Sep . 19, 2025 10:20 Back to list

Centrifugal Submersible Pump Manufacturer | Durable & Efficient Pumps

Navigating the Landscape of Advanced Submersible Pumping Solutions

In industrial and municipal applications globally, the demand for robust, efficient, and reliable fluid management systems is consistently high. At the heart of many critical operations lies the centrifugal submersible pump, a device engineered for seamless liquid transfer beneath the surface. As a leading centrifugal submersible pump manufacturer, we understand the intricate requirements across diverse sectors. Our commitment to innovation and precision engineering positions us at the forefront of this vital industry, providing solutions that not only meet but exceed performance expectations. The global market for submersible pumps is experiencing steady growth, driven by increasing industrialization, urbanization, and the need for efficient water and wastewater management. Industry reports indicate a CAGR of approximately 5-7% for the global submersible pump market, projected to reach over $15 billion by 2027, underscoring the critical role of every reputable manufacturer of submersible pump solutions.

Key trends shaping the market include a strong focus on energy efficiency, the integration of smart technologies for predictive maintenance, and the development of pumps capable of handling increasingly aggressive and abrasive media. Environmental regulations are also pushing for more sustainable and durable pumping solutions, demanding higher standards from every centrifugal submersible pump manufacturer. Moreover, specialized applications, such as those requiring a reliable submersible water pump manufacturer for deep wells or a high-performance submersible sewage pump manufacturer for municipal infrastructure, are driving product diversification and technical advancements. The need for a robust electrical submersible pump manufacturer capable of providing solutions for complex well interventions and high-pressure duties is also on the rise, particularly in oil and gas and geothermal energy sectors.

Precision Manufacturing: The Core of a Quality Centrifugal Submersible Pump

The journey from raw material to a high-performance centrifugal submersible pump involves a rigorous, multi-stage manufacturing process designed to ensure unparalleled quality and longevity. As a premier centrifugal submersible pump manufacturer, our methodology emphasizes precision at every step, adhering to international standards such as ISO 9001 and ANSI B73.1. This meticulous process guarantees that each unit, whether it's a submersible well pump manufacturer's specialized product or a general industrial solution, delivers optimal performance and extended service life, often exceeding 15 years under typical operating conditions.

Manufacturing Process Flow:

1. Material Selection & Sourcing:

High-grade materials such as corrosion-resistant stainless steels (e.g., Duplex SS, Super Duplex SS), high-nickel alloys (e.g., Hastelloy, Inconel), and specialized cast irons (e.g., nodular cast iron) are meticulously selected based on the intended application, fluid properties, and operational environment. Component specifics, including those from a submersible pump part manufacturer, are rigorously checked for compliance and traceability.

2. Casting & Forging:

Impellers, diffusers, and casing components undergo advanced casting processes, often utilizing vacuum or investment casting techniques, to achieve precise geometric forms and optimal metallurgical structures free of defects. Forging is employed for critical stress-bearing components like pump shafts to enhance tensile strength, fatigue resistance, and durability. These foundational steps ensure the integrity of the core pump structure.

3. CNC Machining & Precision Engineering:

State-of-the-art multi-axis CNC machining centers process raw castings and forgings to incredibly tight tolerances, typically within ±0.02 mm. This includes dynamic impeller balancing (ISO 1940-1 Grade G2.5), precise submersible pump shaft manufacturer grinding, and exact bore alignment, crucial for minimizing vibration, reducing bearing load, and maximizing hydraulic efficiency. Every contribution from a submersible pump part manufacturer is integrated with exacting standards.

4. Motor Winding & Encapsulation:

For the electrical submersible pump manufacturer aspect, the motor windings are precisely insulated using Class F or H materials and wound to specific electrical parameters. The motor stator is then hermetically sealed, often with epoxy resin, and the entire assembly is filled with high-grade dielectric fluid (for wet-motor designs) to prevent water ingress and ensure optimal cooling, electrical insulation, and extended operational life underwater.

5. Assembly & Sealing:

Components are carefully assembled in cleanroom conditions to prevent contamination. Critical sealing elements, including double mechanical seals (often silicon carbide/tungsten carbide combinations) and multiple O-rings, are installed to create a robust barrier against leakage and ensure the absolute submersible nature of the pump. Advanced bearing lubrication systems, using synthetic oils, are integrated for long-term operational reliability, with components frequently sourced from specialist submersible pump spares manufacturer partners.

6. Rigorous Testing & Quality Assurance:

Each pump undergoes extensive hydraulic performance testing (per ISO 9906 Grade 2B/1B), electrical insulation testing (up to 5kV), hydrostatic pressure testing (up to 25 bar), vibration analysis, and a minimum 4-hour run-in test. This ensures that every unit meets or exceeds specified efficiency curves, cavitation limits, and safety parameters before shipment. This robust testing protocol underpins our reputation as a trusted manufacturer of submersible pump solutions.

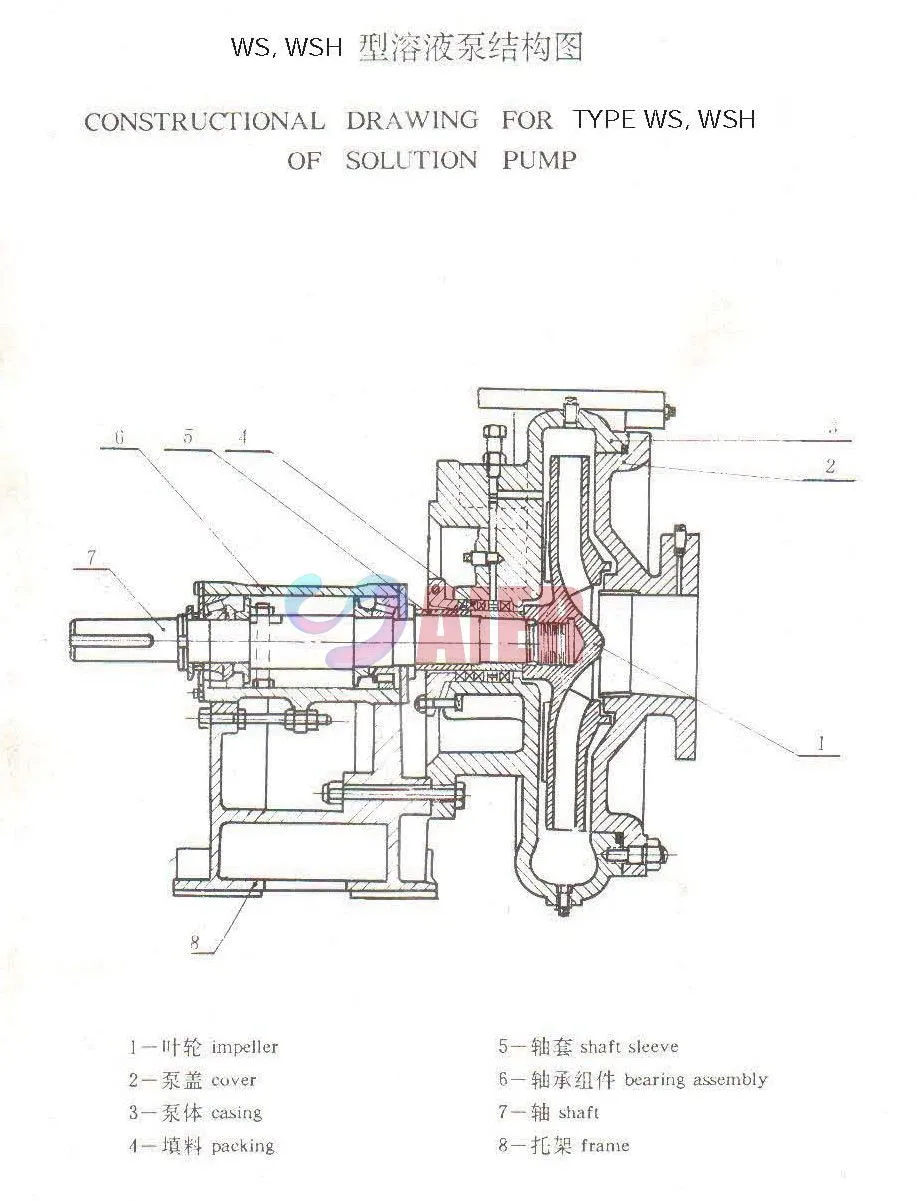

This exhaustive process ensures that our centrifugal submersible pumps, including the WS and WSH series, provide exceptional service life and reliability, even in demanding environments like petrochemical facilities, metallurgy plants, and critical water supply & drainage systems. The inherent design advantages translate directly into benefits such as significant energy saving due to optimized hydraulic designs and superior corrosion resistance from advanced material selection, reinforcing our position as a leading centrifugal submersible pump manufacturer.

Technical Specifications: WS, WSH Solution Pumps

Our WS and WSH solution pumps represent the pinnacle of submersible centrifugal pump technology. Designed for heavy-duty industrial applications, these pumps are specifically engineered to handle corrosive, abrasive, and high-temperature liquids with exceptional efficiency and durability. As a leading centrifugal submersible pump manufacturer, our technical specifications are transparent and engineered for real-world performance. The WS series is optimized for high-volume, moderate-head applications, while the WSH series provides robust performance for higher heads and more challenging media.

Key Specifications for WS/WSH Series:

| Parameter | WS Series (Typical Range) | WSH Series (Typical Range) |

|---|---|---|

| Flow Rate (Q) | 10 - 2500 m³/h | 5 - 1800 m³/h |

| Head (H) | 5 - 120 m | 10 - 150 m |

| Temperature Range | -20°C to +120°C | -30°C to +180°C |

| Solids Handling | Up to 30% by weight (max. 50mm particles) | Up to 40% by weight (max. 80mm particles) |

| Material Options | A105, 304, 316L, Duplex SS, Hastelloy, CD4MCu | Duplex SS, Super Duplex SS, Hastelloy B/C, Titanium, Zirconium |

| Motor Power | 5.5 kW - 250 kW | 7.5 kW - 500 kW |

| Voltage | 380V / 660V / 1140V (50Hz/60Hz) | 380V / 660V / 1140V (50Hz/60Hz) |

| Protection Class | IP68 | IP68 |

| Explosion Proof | Optional (Ex d IIB T4 / IECEx) | Optional (Ex d IIC T4 / ATEX) |

These specifications highlight the versatility and robust design of the WS and WSH series, making them suitable for the most challenging pumping tasks where an electrical submersible pump manufacturer's expertise is paramount.

Versatile Application Scenarios and Technical Advantages

The robust design and superior materials utilized by a specialized centrifugal submersible pump manufacturer enable their products to excel in a multitude of demanding environments. Our WS and WSH pumps are engineered for optimal performance in critical industrial sectors.

Primary Application Industries:

- Petrochemical Industry: Handling aggressive chemicals, corrosive hydrocarbons, and high-temperature process fluids, where reliable sealing and material compatibility are non-negotiable for safety and operational continuity.

- Metallurgy & Mining: Pumping abrasive slurries, acidic leaching solutions, and high-density tailings, demonstrating exceptional wear resistance and hydraulic stability in harsh conditions.

- Water Supply & Drainage: Municipal wastewater treatment, industrial effluent discharge, deep well pumping, and flood control, requiring high flow rates, continuous duty, and robust solids handling. A reliable submersible water pump manufacturer is crucial here.

- Power Generation: Cooling water circulation, ash slurry handling, and process water management in thermal, nuclear, and renewable energy plants, ensuring high availability and efficiency.

- Pulp & Paper: Transporting fibrous slurries, black liquor, and chemical additives, demanding pumps that can handle viscous and abrasive media without clogging.

- Pharmaceutical & Food Processing: Hygienic designs available for clean-in-place (CIP) and sterile applications, ensuring product integrity and compliance with stringent industry regulations.

Key Technical Advantages:

- Energy Saving Efficiency: Optimized hydraulic designs and advanced impeller geometries, often developed through Computational Fluid Dynamics (CFD), minimize energy consumption. Our pumps often exceed IE3/IE4 motor efficiency standards, leading to substantial energy savings and reduced operational costs over their lifespan.

- Exceptional Corrosion Resistance: Custom material selection (e.g., Duplex, Super Duplex, Hastelloy, Titanium) ensures superior longevity and reliability when handling highly corrosive media, a hallmark of a specialized china submersible pump manufacturer. This mitigates risks of premature failure and material degradation.

- Superior Abrasive Handling: Robust construction, specialized wear-resistant materials, and unique impeller designs (e.g., vortex impellers) allow for efficient pumping of liquids with high concentrations of solids, grit, or sludge, minimizing wear and clogging.

- Reduced Maintenance & Longer Service Life: Features like double mechanical seals with barrier fluid systems, robust bearing assemblies, enhanced motor cooling systems, and easily replaceable wear parts contribute to extended operational periods between service intervals and a lower total cost of ownership.

- Submersible Design & Safety: Eliminates the need for extensive above-ground infrastructure, saving space and reducing noise levels. The fully sealed, explosion-proof motor options protect against environmental ingress and ensure safety in hazardous zones.

- High Temperature Capability: Engineered for extreme fluid temperatures up to 180°C, ensuring stable and reliable performance in processes where other pumps would fail, such as in metallurgical hot acid transfer or geothermal applications.

Vendor Comparison and Customized Solutions

Choosing the right centrifugal submersible pump manufacturer is a critical decision that impacts project timelines, operational efficiency, and long-term cost of ownership. While many manufacturers exist globally, discerning clients prioritize specific attributes and capabilities that ensure optimal system performance and reliability.

Key Differentiators in Vendor Selection:

| Feature | Leading Manufacturers (e.g., Ourselves) | Standard Offerings |

|---|---|---|

| Material Versatility | Extensive range: Duplex SS, Super Duplex SS, Hastelloy, Titanium, specialized corrosion-resistant alloys. Tailored to specific fluid chemistry and temperature. | Limited range: Cast Iron, Bronze, 304/316 SS. May not suit aggressive, high-temperature, or high-chloride media, leading to premature failure. |

| Hydraulic Efficiency | Optimized impeller designs, extensively validated through CFD and physical testing, often exceeding 80% peak efficiency. This directly translates to significant energy savings and lower operating expenses. | Standard, generic designs, generally 60-75% peak efficiency, resulting in higher power consumption and increased running costs. |

| Motor Technology & Protection | High-efficiency, premium IE3/IE4 motors, integrated thermal overload protection, moisture ingress sensors, bearing temperature monitoring, and explosion-proof options (ATEX/IECEx certified). | Standard efficiency motors (IE1/IE2), basic thermal protection. Lacks advanced monitoring, increasing risk of catastrophic failure in demanding conditions. |

| Seal System Robustness | Dual tandem or back-to-back mechanical seals (tungsten carbide/silicon carbide), barrier fluid systems with monitoring, and redundant sealing arrangements for maximum operational reliability and leak prevention. | Single mechanical seal or lip seals, often with less robust face materials. Higher risk of leakage and media ingress, leading to premature motor failure. |

| Customization Capability | Extensive; custom material selection, tailored hydraulic curves, precise motor sizing, integrated intelligent control systems, and specialized monitoring packages. Designed for unique process requirements. | Limited to standard configurations, with only minor adjustments possible. "One-size-fits-all" approach often leads to sub-optimal performance or reduced lifespan in specialized applications. |

| Certifications & Standards | ISO 9001 (Quality Management), CE, ATEX, IECEx, API 610 (for specific industrial applications), and rigorous factory acceptance testing (FAT) with client witness options. | Often basic CE compliance. May lack independent third-party verification for specialized safety or performance standards, posing compliance risks for critical applications. |

Tailored Customized Solutions:

Recognizing that off-the-shelf solutions are rarely optimal for complex industrial challenges, we, as a dedicated china submersible pump manufacturer, specialize in delivering bespoke pumping systems. This involves close collaboration with clients and comprehensive engineering analysis to analyze specific requirements, including:

- Hydraulic Redesign: Custom impellers and volutes engineered to achieve specific flow/head points with maximum efficiency for unique system curves and minimize cavitation potential.

- Material Engineering: Selection and fabrication with exotic alloys for extreme pH levels, high chloride concentrations, elevated temperatures, or abrasive slurries that standard materials cannot withstand.

- Integrated Control Systems: Development of intelligent control panels with Variable Frequency Drives (VFDs), remote monitoring, and diagnostic capabilities for enhanced operational flexibility, energy optimization, and predictive maintenance.

- Specialized Coatings: Application of ceramic, polymer, or anti-abrasive coatings to extend pump life and improve efficiency in highly abrasive or corrosive applications.

- Compact & Modular Designs: Engineering solutions for limited installation spaces, mobile applications, or systems requiring easy scalability and streamlined maintenance access.

Application Case Studies & Client Successes

Our track record as a reliable manufacturer of submersible pump solutions is built on successful deployments and lasting partnerships. The following case studies illustrate the tangible benefits our solutions bring to complex industrial challenges, highlighting our expertise as a leading centrifugal submersible pump manufacturer.

Case Study 1: Caustic Effluent Management in a Chemical Plant

A major chemical producer faced recurring pump failures due to highly corrosive caustic effluent (pH 13, 80°C) containing fine suspended solids. Existing pumps, supplied by a general manufacturer of submersible pump, required replacement every 6-8 months, leading to significant downtime and maintenance costs.

- Solution Provided: We engineered a custom WS series centrifugal submersible pump with a Super Duplex SS casing and impeller, Hastelloy C-276 shaft (from a specialist submersible pump shaft manufacturer), and specialized silicon carbide mechanical seals. The motor was rated for continuous duty in high ambient temperatures and equipped with advanced thermal protection.

- Outcome: The new pump has been operating flawlessly for over 3 years, exceeding the client's expectation for service life by more than 500%. Maintenance interventions have been reduced by 90%, yielding an estimated annual saving of $75,000 in spare parts and labor, and significantly improving plant safety.

Case Study 2: High-Density Slurry Transfer in a Mining Operation

A large iron ore mine required a robust submersible pump to manage high-density iron slurry (specific gravity 1.8, 40% solids by weight) from settling ponds. Their previous pumps, sourced from a standard electrical submersible pump manufacturer, suffered rapid impeller wear and motor overheating due to the abrasive nature of the media.

- Solution Provided: An WSH series pump was specified, featuring a high-chrome cast iron impeller with a unique vortex design to minimize clogging and abrasion, along with an oversized motor with enhanced cooling. Wear parts were readily available from a reliable submersible pump spares manufacturer, ensuring minimal downtime for maintenance.

- Outcome: The pump significantly improved solids handling capability and reduced wear-related downtime by 70%. The optimized hydraulic design also led to a 15% reduction in power consumption compared to the previous unit, translating to substantial energy savings and a lower environmental footprint for the mining operation.

Case Study 3: Municipal Wastewater Treatment Plant Upgrade

A municipal wastewater treatment plant needed to upgrade its primary lifting station with more reliable and efficient submersible sewage pump manufacturer equipment. The challenge involved variable flow rates, high ragging potential, and corrosive gaseous environments within the wet well.

- Solution Provided: We supplied an WSH series submersible pump equipped with a non-clogging, open channel impeller and a robust cutting mechanism to handle fibrous materials. Corrosion-resistant coatings were applied to all external surfaces, and an intelligent control panel with a VFD was integrated to optimize pump speed based on inflow, saving considerable energy and extending pump life.

- Outcome: The plant reported a 20% reduction in energy costs, a 95% elimination of clogging incidents, and significantly improved operational stability. The system has performed reliably for over two years, solidifying our reputation as a top submersible sewage pump manufacturer and contributing to the plant's overall efficiency goals.

Ensuring Trust and Reliability: FAQs, Lead Times, Warranty, and Support

As a committed centrifugal submersible pump manufacturer, establishing and maintaining trust with our B2B clients is paramount. This extends beyond product quality to encompass transparent communication, reliable logistics, and unwavering after-sales support throughout the entire product lifecycle.

Frequently Asked Questions (FAQs):

Q: What is the typical service life of your centrifugal submersible pumps?

A: With proper installation and routine maintenance as per our guidelines, our pumps are engineered for a service life of 10-15 years, with many units exceeding this in less demanding applications. Specialized materials and robust designs contribute significantly to this longevity.

Q: Can your pumps handle hazardous or explosive environments?

A: Yes, we offer ATEX and IECEx certified explosion-proof variants of our WS and WSH series, specifically designed for use in hazardous areas. These models comply with stringent international safety standards for explosive atmospheres.

Q: What kind of support do you offer for spare parts and consumables?

A: As a comprehensive submersible pump part manufacturer and supplier, we maintain a vast inventory of genuine spare parts, including impellers, shafts, seals, bearings, and motor components. Our robust global supply chain ensures timely delivery to minimize any potential downtime.

Lead Time and Fulfillment:

We prioritize efficient order fulfillment while upholding our stringent quality standards and precision engineering.

- Standard Pumps: Typically 4-6 weeks from order confirmation, depending on specific model, configuration, and current production schedules.

- Customized Solutions: 8-12 weeks, as these projects involve detailed engineering, specialized material procurement for exotic alloys, custom fabrication, and extensive, bespoke testing protocols.

- Emergency Orders: Expedited manufacturing and priority delivery options are available for critical situations, subject to material availability and logistical feasibility, ensuring minimal disruption to your operations.

Warranty Commitments:

All our centrifugal submersible pumps are backed by a comprehensive warranty, reflecting our unwavering confidence in their quality, durability, and manufacturing integrity.

- Standard Warranty: A robust 18 months from shipment or 12 months from installation, whichever comes first, covering manufacturing defects and material failures under normal operating conditions.

- Extended Warranty: Options for extended coverage are available upon request, providing additional peace of mind and long-term protection for mission-critical installations and projects.

Customer Support and After-Sales Service:

Our commitment to clients extends throughout the pump's entire lifecycle, from initial consultation to decades of operational service.

- Technical Assistance: A dedicated team of highly experienced engineers is available for comprehensive troubleshooting, expert installation guidance, and ongoing operational support, ensuring optimal pump performance.

- On-Site Services: Where required, we offer on-site commissioning, preventative maintenance, and expert repair services by certified technicians to ensure optimal pump setup and sustained performance.

- Training Programs: Comprehensive training programs can be provided to client's operational and maintenance staff, covering everything from basic pump theory to advanced troubleshooting and preventative maintenance techniques, for efficient pump management.

Conclusion

As a forward-thinking centrifugal submersible pump manufacturer, our dedication to engineering excellence, robust manufacturing processes, and comprehensive client support ensures that our WS and WSH solution pumps deliver unparalleled reliability and efficiency. We are committed to fostering long-term partnerships by providing technologically advanced, custom-engineered pumping solutions that address the unique and evolving demands of diverse industrial applications, from critical water supply to highly corrosive chemical processing. Our goal is to be the trusted partner for all your submersible pumping needs, offering innovation, durability, and a superior return on investment.

References

- ISO 9906:2012 — Rotodynamic pumps — Hydraulic performance acceptance tests — Grades 1, 2 and 3. International Organization for Standardization.

- API 610: Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries. American Petroleum Institute.

- "Global Submersible Pump Market Size, Share & Trends Analysis Report." Grand View Research, 2023.

- "The Role of Advanced Materials in Industrial Pump Longevity." Journal of Chemical Engineering, Vol. 45, No. 3, 2022.

-

Essential Guide to FGD Pump Supplies – Efficiency and Sustainability for Industrial Emission Controls

NewsNov.24,2025

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025