- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 18, 2025 15:46 Back to list

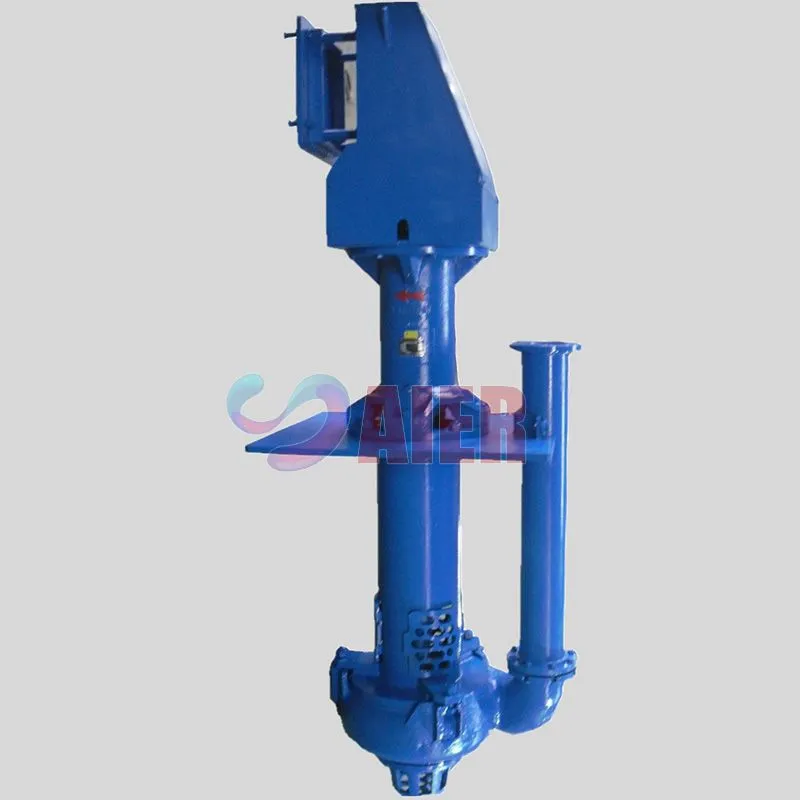

A Comprehensive Overview of Vertical Slurry Pumps

In industrial fluid management, vertical slurry pumps stand as indispensable solutions for handling abrasive, high-density slurries. These pumps are engineered to thrive in demanding environments where standard pumps falter, offering robust performance tailored to unique operational challenges. This article explores the technical nuances and practical applications of key pump types, highlighting their role in optimizing industrial processes.

Structural Elements of Vertical Slurry Pumps

A vertical slurry pump is a marvel of mechanical engineering, constructed with components designed to withstand the rigors of slurry transportation. The pump casing, often fabricated from wear-resistant materials like high-chromium alloy or polyurethane, forms the protective shell around the impeller a critical component responsible for converting rotational energy into hydraulic force to move dense slurries. The vertical orientation minimizes floor space, making it ideal for installations with spatial constraints, such as wastewater treatment plants or mineral processing facilities.

The shaft assembly, a central structural element, must endure axial and radial forces exerted by the slurry, requiring precision engineering and durable bearings to maintain alignment and reduce vibration. Sealing systems, such as mechanical seals or expeller rings, prevent leakage and protect against corrosive fluids, ensuring safe and efficient operation. Suction and discharge nozzles are optimized for fluid dynamics, reducing turbulence and wear to enhance the pump’s service life.

Technological Superiorities and Design Attributes of Vertical Shaft Slurry Pumps

The vertical spindle slurry pump distinguishes itself through its specialized spindle design, a technological advancement that enhances stability and operational efficiency. The spindle, a reinforced shaft connecting the impeller to the drive motor, is supported by multiple bearings to minimize deflection, enabling high-speed operation with minimal vibration critical for high-head applications where precision and consistency are paramount.

Compared to conventional vertical pumps, this design offers superior suction performance, as the impeller is positioned closer to the fluid source, reducing the risk of cavitation. Its compact footprint facilitates integration into existing systems, particularly in industries like mining or chemical processing where equipment must fit into tight, multi-level setups. The modular architecture further simplifies maintenance, allowing quick replacement of wear parts such as impellers or casings without dismantling the entire pump assembly, thus minimizing downtime.

China Vertical Slurry Pumps A Benchmark of Quality and Innovation

China vertical slurry pumps have emerged as global leaders in industrial pump technology, combining advanced manufacturing expertise with cost-effective solutions. Chinese manufacturers leverage rigorous quality control protocols and cutting-edge materials such as epoxy-coated ductile iron or composite polymers to create pumps that meet international standards for durability and performance. These pumps are available in diverse configurations, from small scale units for municipal wastewater to heavy-duty models for mining and dredging operations.

A hallmark of china vertical slurry pumps is their adaptability to harsh conditions. High-chromium alloy linings and rubber coatings enhance resistance to abrasion and corrosion, ensuring reliable operation even when handling slurries laden with sand, gravel, or chemical byproducts. Customization is another strength, with manufacturers collaborating closely with clients to engineer pumps that match specific flow rates, pressure requirements, and environmental constraints, delivering optimized performance and long term value.

Submerged Mining Vertical Slurry Pumps Specialized for Underwater Operations

In the mining sector, submerged mining vertical slurry pumps are essential for extracting and transporting slurries from submerged environments, such as tailings ponds, underwater excavation sites, or dewatering deep mine shafts. These pumps are designed to operate fully submerged, eliminating the need for priming and ensuring continuous flow in low-suction conditions a critical advantage in remote or hard-to-access locations.

Their construction features hermetically sealed motor compartments and reinforced casings to prevent water ingress, combined with high efficiency impellers. This design reduces clogging risks and maintains productivity in applications like ore slurry transportation from underwater mines to processing plants. The pumps’ robust build also withstands the corrosive effects of saltwater or chemically treated slurries, making them indispensable in marine mining and offshore operations.

Vertical Slurry Pumps FAQs

What key industries benefit most from vertical slurry pumps?

Vertical slurry pumps are vital in mining, where they transport ore slurries; wastewater treatment, for managing sludge and debris; and construction, for dredging applications. Their ability to handle abrasive materials makes them irreplaceable in high-solid-content fluid management.

How does a vertical spindle slurry pump enhance operational stability?

The vertical spindle slurry pump incorporates a reinforced spindle with multi-bearing support, reducing shaft deflection and vibration during high-speed operation. This design ensures consistent performance in high-pressure industrial processes.

What factors make china vertical slurry pumps a global preference?

China vertical slurry pumps are favored for their quality, innovation, and affordability. Advanced materials and strict quality controls ensure compliance with international standards, making them reliable for global projects.

In which scenarios are submerged mining vertical slurry pumps essential?

Submerged mining vertical slurry pumps excel in tailings management, underwater mineral extraction, and dewatering flooded mines, providing continuous slurry transfer in challenging aquatic environments.

What maintenance practices extend the life of vertical slurry pumps?

Regular inspection of wear parts like impellers and seals, along with proper shaft alignment and material compatibility, significantly extends a vertical slurry pump’s service life.

Vertical slurry pumps, including vertical spindle slurry pump and china vertical slurry pump, represent critical advancements in industrial fluid handling. Their specialized designs address the challenges of abrasive slurries, delivering reliability and efficiency across diverse sectors. By understanding their engineering and applications, industries can optimize processes and ensure safety in demanding environments.

This article highlights the technical features and applications of vertical slurry pumps, focusing on the stability of vertical spindle slurry pumps and the global excellence of china vertical slurry pumps. It emphasizes maintenance best practices and industry relevance, underscoring their role in efficient slurry management.

-

Essential Guide to FGD Pump Supplies – Efficiency and Sustainability for Industrial Emission Controls

NewsNov.24,2025

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025