Dec . 29, 2024 11:53 Back to list

Vertical Centrifugal Slurry Pump Manufacturers and Their Innovative Solutions for Heavy-Duty Applications

Understanding Vertical Centrifugal Slurry Pumps A Focus on Manufacturing

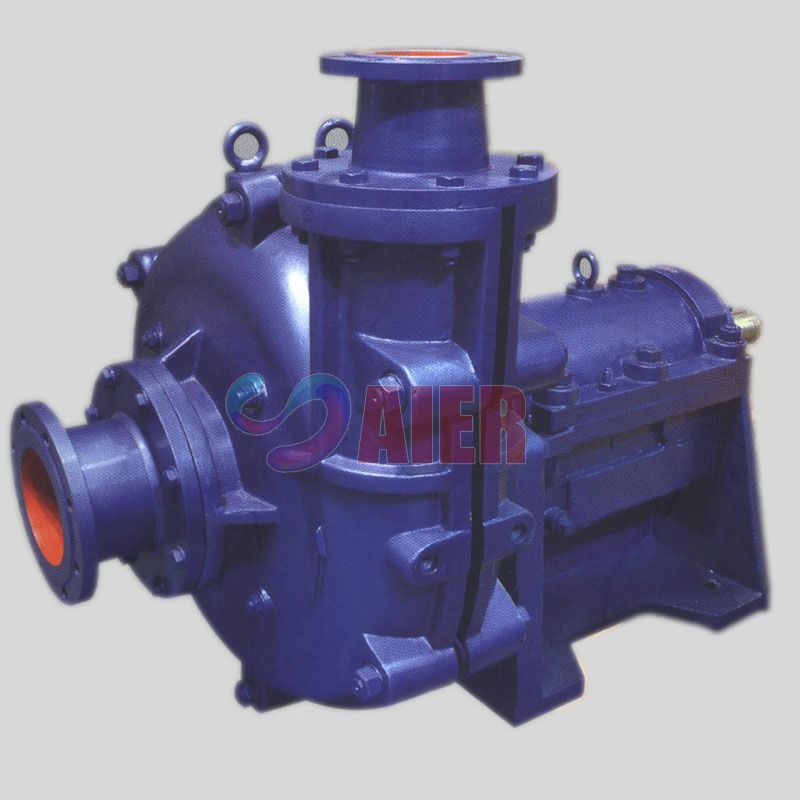

Vertical centrifugal slurry pumps play a crucial role in various industries, especially in sectors where the movement of viscous or abrasive liquids is required. These pumps are specifically designed to handle slurries—mixtures of solids and liquids—including those found in mining, dredging, and wastewater management. This article explores the significance of vertical centrifugal slurry pump factories, their manufacturing processes, and the applications of these pumps.

What Are Vertical Centrifugal Slurry Pumps?

Vertical centrifugal slurry pumps are distinguished by their vertical orientation and centrifugal design, allowing them to efficiently transport slurries with high solid content. The vertical design is particularly beneficial in applications where space is limited, and it also minimizes the risk of cavitation, which can damage pump components.

These pumps are engineered to handle abrasive materials, making them suitable for industries like mining, where they are used to transport slurries of ore and waste. The robust construction of these pumps, often using materials like high-chrome alloys, ensures durability and a long service life even under the toughest conditions.

Manufacturing Processes

The manufacturing of vertical centrifugal slurry pumps involves several key processes

1. Material Selection The choice of materials is critical for the pump's performance and durability. Stainless steels and high-chrome alloys are commonly used to provide resistance to abrasion and corrosion.

2. Casting and Machining The initial components of the pump, such as the casing and impeller, are typically cast from selected metal alloys. Once cast, these components undergo machining to achieve precise dimensions and tolerances that are crucial for operational efficiency.

3. Assembly After machining, the components are assembled. This stage involves fitting the impeller, motor, and other components together to ensure proper functioning. Engineers pay close attention to alignments and seals to prevent leaks and enhance performance.

4. Testing Before being dispatched, pumps undergo rigorous testing to evaluate their performance under various conditions. This includes checking for flow rates, pressure levels, and efficiency. Quality control teams assess the pumps to ensure they meet both industry standards and customer specifications.

vertical centrifugal slurry pump factories

5. Surface Treatment To enhance longevity, pumps often undergo surface treatments such as painting or coating with protective materials to guard against corrosion and wear.

Applications of Vertical Centrifugal Slurry Pumps

Vertical centrifugal slurry pumps find applications across various industries

- Mining They are integral in ore transportation, allowing miners to pump slurries from mines to processing facilities efficiently.

- Dredging In dredging operations, these pumps facilitate the removal of sediments and debris from bodies of water, helping to maintain navigable waterways.

- Wastewater Management They are essential in wastewater treatment plants, helping convey sludge and other slurry byproducts through the treatment processes.

- Construction During construction activities, these pumps manage concrete and other slurry mixtures, ensuring smooth handling and application.

The Future of Vertical Centrifugal Slurry Pump Manufacturing

As industries continue to evolve and focus on sustainability, manufacturers of vertical centrifugal slurry pumps are also adapting. Innovations in pump design, materials, and energy efficiency are on the rise, driven by the need for more environmentally friendly and cost-effective solutions. Smart technologies that incorporate IoT for real-time monitoring and automated adjustments are beginning to be integrated, offering better performance and maintenance alerts.

In conclusion, vertical centrifugal slurry pump factories play a vital role in the production of equipment crucial for various industries. Their manufacturing processes emphasize quality and durability, ensuring that the pumps can handle the demanding conditions associated with transporting slurries. As technology continues to advance, these factories will likely push boundaries, leading to even more efficient and innovative pumping solutions that meet the needs of a changing industrial landscape.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025