Aug . 15, 2024 14:14 Back to list

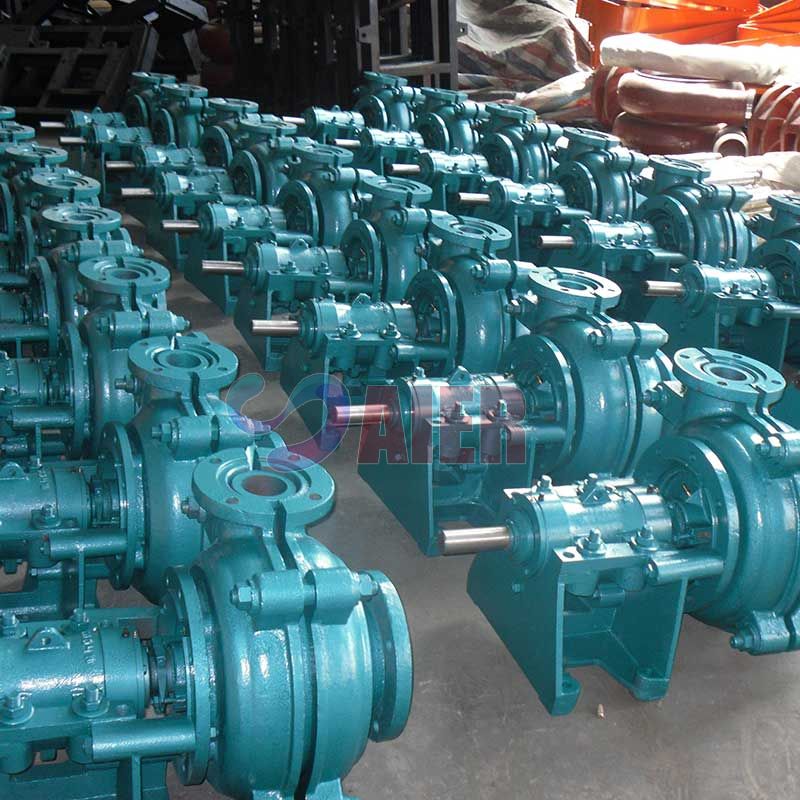

Top Manufacturers of Durable and Efficient Chemical Centrifugal Slurry Pumps for Industrial Applications

High-Quality Chemical Centrifugal Slurry Pump Manufacturers

In the industrial sector, the effective transport of slurry—mixtures of liquids and solids—plays a critical role in many operations, particularly in mining, chemical processing, and wastewater management. Central to this process is the performance of pumps, with chemical centrifugal slurry pumps being essential for handling abrasive and corrosive materials. This article will explore the attributes of high-quality chemical centrifugal slurry pump manufacturers and what sets them apart in the marketplace.

Understanding Chemical Centrifugal Slurry Pumps

Chemical centrifugal slurry pumps are designed to move slurry at varying flow rates and pressures. These pumps utilize centrifugal force to transfer high-density fluids efficiently. Their applications include transporting ores, minerals, and even sludge, necessitating robust construction and reliable performance. With the harsh environments they operate in, it is crucial that these pumps withstand erosion and corrosion while delivering consistent output.

Key Features of High-Quality Manufacturers

1. Quality of Materials Leading manufacturers utilize advanced materials such as high-chrome alloys and rubber linings that are crafted to resist wear and corrosion. This ensures durability, extending the life of the pump and reducing maintenance costs.

2. Innovative Design High-caliber manufacturers prioritize innovative engineering designs that enhance pump performance. This includes features like adjustable impellers and volutes that can be tailored to specific applications. Furthermore, the hydraulic design is optimized for high efficiency, reducing energy consumption.

3. Custom Solutions The best manufacturers understand that slurry applications can vary widely from one industry to another. Therefore, they offer customizable pumping solutions tailored to the specific requirements of their clients. This might include varying the size, capacity, and materials used, thus providing enhanced service efficiency.

high quality chemical centrifugal slurry pump manufacturers

4. Research and Development Significant investment in R&D is a hallmark of top-tier manufacturers. Continuous innovation leads to the development of pumps that exhibit improved performance metrics, such as higher efficiencies and lower maintenance needs. This adaptation to market demands ensures that manufacturers stay ahead of the curve.

5. Stringent Quality Control High-quality manufacturers adhere to strict quality control processes. Each pump undergoes rigorous testing to evaluate its performance under various conditions. This commitment to quality not only ensures reliability but also enhances customer confidence.

6. Comprehensive Support and Service Renowned manufacturers understand the importance of after-sales support. They provide thorough documentation, installation guidance, and prompt service for repairs or replacement parts. An established customer service department is invaluable for addressing concerns quickly and effectively.

Leading Players in the Market

While there are numerous manufacturers globally, a few stand out due to their commitment to quality and innovation. Companies like Goulds, Weir Minerals, and Schurco Slurry have established reputations for producing reliable and efficient pumps suited for a variety of heavy-duty applications. Their involvement in projects across different sectors showcases their expertise and adaptability.

Conclusion

Choosing the right chemical centrifugal slurry pump manufacturer is critical for businesses aiming to optimize their operations. High-quality manufacturers exhibit a combination of innovative design, durable materials, custom solutions, and excellent customer service. As industries continue to evolve, the demand for efficient and reliable slurry handling will only grow, making the role of these manufacturers even more significant in the years to come. Therefore, businesses must invest time in selecting a manufacturing partner that aligns with their operational needs and quality standards. This proactive approach will ultimately contribute to enhanced efficiency, reduced costs, and improved overall productivity.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025