Nov . 26, 2024 03:03 Back to list

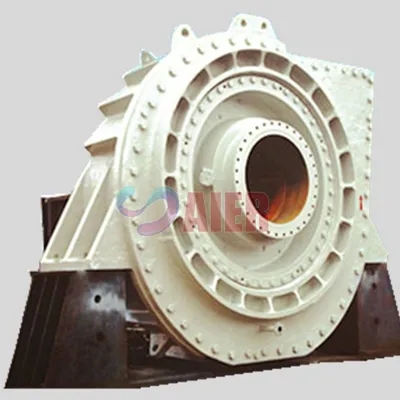

China Slurry Pump Impeller Material Manufacturing Solutions for Enhanced Performance and Durability

Exploring Slurry Pump Impeller Materials in China's Manufacturing Industry

In the global landscape of engineering and manufacturing, slurry pumps play a pivotal role across various sectors, including mining, construction, and wastewater treatment. Slurry pumps are designed to transport abrasive and viscous fluids, often containing solid particles. One of the critical components of these pumps is the impeller, which directly affects performance, efficiency, and durability. This article will delve into the different materials used in manufacturing slurry pump impellers in China, highlighting their advantages, applications, and innovation in the industry.

Understanding Slurry Pump Impellers

The impeller in a slurry pump is responsible for conveying the mixed slurry through the pump system. It achieves this by imparting kinetic energy to the fluid, which is then converted into pressure. Given that slurry pumps frequently handle harsh materials, the choice of impeller material is vital. A good impeller material must withstand erosion, corrosion, and fatigue while maintaining optimal performance.

Common Impeller Materials

1. Cast Iron Cast iron is one of the most traditional materials used for slurry pump impellers. It offers excellent wear resistance, good tensile strength, and is relatively cost-effective. However, its vulnerability to corrosion in certain environments limits its application, particularly in chemical slurry transport.

2. High Chromium Alloy High chromium alloy impellers are designed specifically for abrasive applications. This material boasts exceptional hardness and wear resistance due to its high chromium content, making it suitable for slurries containing fine particles. Impellers made from high chromium alloy are commonly used in mining and mineral processing industries, where abrasion is a significant concern.

3. Rubber-lined Impellers Rubber is another popular choice, particularly in environments where corrosion is a critical issue. A rubber-lined impeller can effectively handle acidic or caustic slurries, as rubber provides excellent chemical resistance. However, while rubber can withstand corrosive environments, it may not be as effective against abrasive forces as metal materials.

china slurry pump impeller material factory

4. Polyurethane Polyurethane is gaining traction in slurry pump manufacturing due to its flexibility and durability. It offers a middle ground between rubber and metal materials, providing good wear resistance and chemical compatibility. Impellers made of polyurethane are increasingly used in applications that require less aggressive abrasion resistance combined with chemical durability.

5. Stainless Steel In environments that demand both strength and corrosion resistance, stainless steel impellers are often utilized. They are particularly suitable for food processing and wastewater applications, where hygiene is essential. While stainless steel may not perform as well in high-abrasion environments compared to high chromium alloys, its resistance to corrosion makes it a preferred choice in many industries.

Innovations in Impeller Material Design

The slurry pump industry in China is characterized by continuous innovation. Manufacturers are investing in research and development to create new materials and improve existing ones. For instance, advancements in composite materials have led to the creation of hybrid impellers that enhance resistance to both abrasion and corrosion, providing a longer lifespan and improved efficiency.

Moreover, the use of advanced manufacturing techniques, such as 3D printing, is transforming how impellers are designed and produced. This technology allows for more complex geometries that can optimize fluid dynamics and increase pumping efficiency. Customized solutions tailored to specific applications are becoming more feasible, thanks to rapid prototyping and on-demand manufacturing capabilities.

Conclusion

The material choice for slurry pump impellers is crucial to the efficiency, durability, and performance of the pumps. China's manufacturing sector demonstrates a diverse range of materials, each suited for specific applications and environmental conditions. As industries evolve and face new challenges, the ongoing innovations in materials and manufacturing processes are likely to enhance the effectiveness of slurry pumps, positioning them as essential components in various industrial applications. With a keen focus on research and development, manufacturers in China are well-equipped to meet the demands of a continually changing market.

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025