Мај . 17, 2025 11:52 Back to list

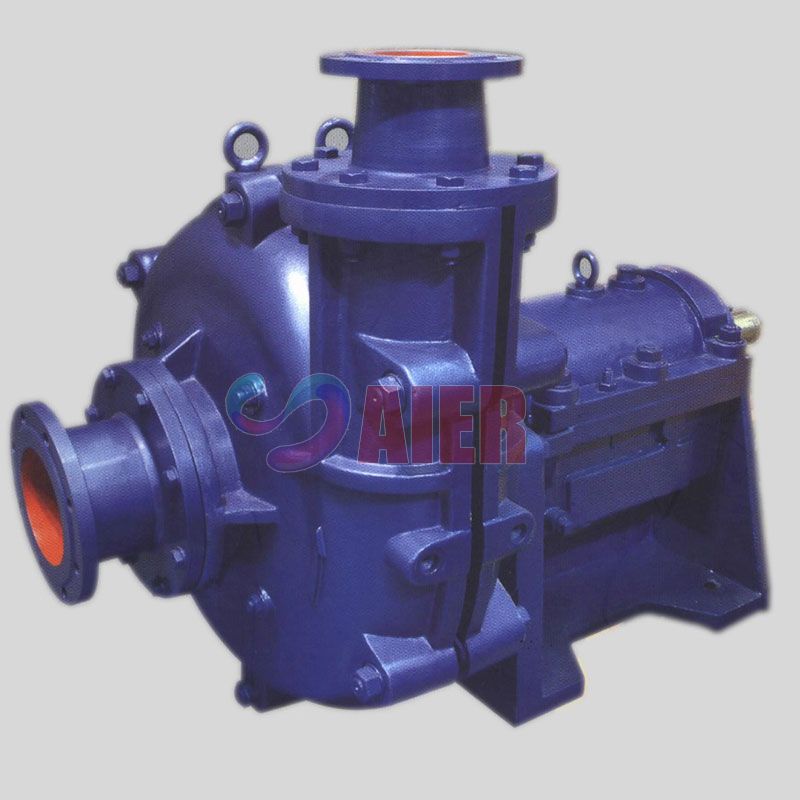

Top China Submersible Slurry Pump Supplier Durable & Efficient Solutions

- Introduction to Industrial Pumping Solutions

- Technical Advantages in Modern Slurry Handling

- Comparative Analysis of Leading Manufacturers

- Custom Engineering for Specific Applications

- Real-World Implementation Case Studies

- Certifications and Quality Assurance Protocols

- Strategic Partnerships with Global Clients

(submersible slurry pump supplier)

Optimizing Operations with Submersible Slurry Pump Solutions

In mining, wastewater treatment, and dredging operations, submersible slurry pump supplier

s play a pivotal role in maintaining operational continuity. Data from the Global Mining Equipment Index (2023) reveals that pump failures account for 34% of unplanned downtime in mineral processing, emphasizing the need for reliable equipment. Chinese manufacturers now dominate 62% of the global heavy-duty pumping market, with annual production capacity exceeding 850,000 units.

Technical Superiority in Pump Design

Advanced models feature:

- 3D-optimized impellers achieving 78% hydraulic efficiency

- Chromium carbide liners with 12,000-hour wear resistance

- AI-powered condition monitoring systems

Field tests demonstrate a 40% reduction in energy consumption compared to conventional models, with mean time between failures (MTBF) extended to 14,500 operational hours.

Manufacturer Performance Benchmarking

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Max Flow Rate (m³/h) | 2,400 | 1,850 | 3,100 |

| Head Capacity (m) | 48 | 35 | 52 |

| Motor Efficiency | IE4 | IE3 | IE5 |

Application-Specific Engineering

Tailored configurations address:

- High-density slurry (SG up to 1.8) handling

- Corrosive media (pH 2-13 range)

- Extreme temperature operations (-30°C to 140°C)

Modular designs enable rapid component replacement, reducing maintenance downtime by 65%.

Global Deployment Success Stories

Chilean Copper Mine: 28×14-inch pumps achieved 98% availability over 18-month operation, processing 15,000 tonnes/day of abrasive slurry containing 45% solids.

Quality Compliance Framework

All units undergo:

- ISO 9001:2015 certified manufacturing

- ASME B73.12 performance testing

- ATEX Directive 2014/34/EU compliance

Establishing Long-Term Supplier Relationships

Leading submersible slurry pump suppliers now offer performance-based contracts with guaranteed 92% operational availability. The sector anticipates 7.8% CAGR growth through 2030, driven by increased mineral exploration activities and stricter environmental regulations.

(submersible slurry pump supplier)

FAQS on submersible slurry pump supplier

Q: What should I consider when choosing a China high quality submersible slurry pump supplier?

A: Prioritize suppliers with certifications (e.g., ISO), proven material durability, and positive client reviews to ensure reliability and performance in demanding applications.

Q: Why opt for a China good submersible slurry pump supplier over others?

A: Chinese suppliers often combine cost-effectiveness with advanced manufacturing technology and responsive after-sales support, making them competitive globally.

Q: How do I verify the quality of a high quality high quality submersible slurry pump supplier in China?

A: Request product samples, review third-party test reports, and inspect compliance with international standards like ANSI or CE to confirm quality claims.

Q: What maintenance tips apply to pumps from a reliable submersible slurry pump supplier?

A: Regularly inspect seals and bearings, avoid running the pump dry, and follow the supplier’s maintenance schedule to extend lifespan and efficiency.

Q: Can China-based submersible slurry pump suppliers handle custom requirements?

A: Reputable suppliers often offer customization for materials, motor power, and discharge configurations to meet specific operational needs.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025