ឧសភា . 16, 2025 11:39 Back to list

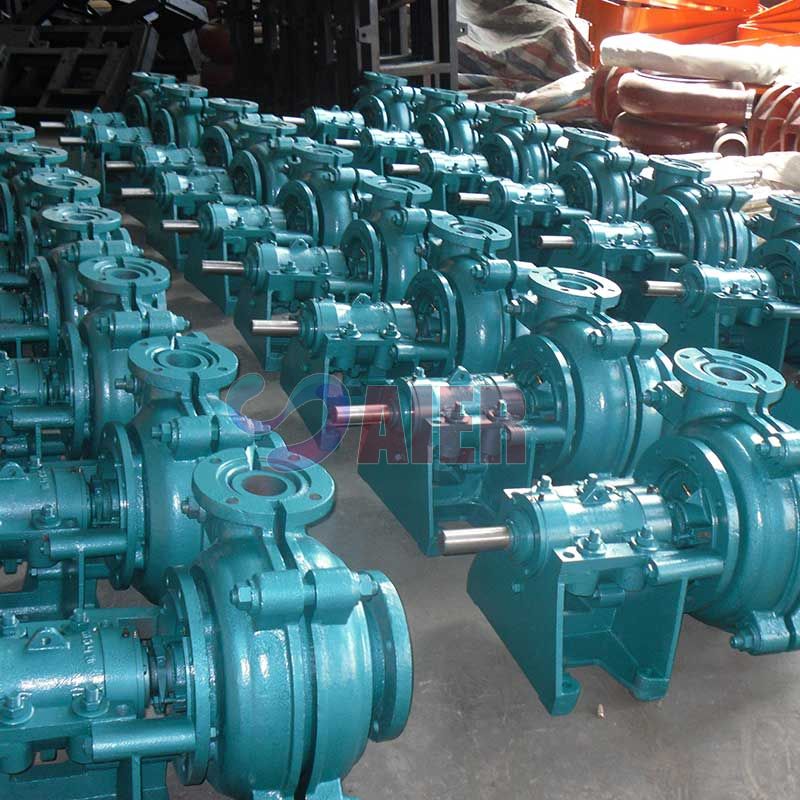

High-Quality Casting Submersible Pump Parts Manufacturer Durable Solutions

- Industry Overview & Importance of Specialized Components

- Technical Superiority in Material Engineering

- Performance Comparison: Leading Manufacturers Analyzed

- Customized Solutions for Diverse Operational Needs

- Real-World Applications Across Industries

- Sustainability & Manufacturing Compliance

- Future Trends in Submersible Pump Component Design

(submersible pump part manufacturer)

Submersible Pump Part Manufacturer: Engineering Excellence Below the Surface

Global demand for submersible pump components surged by 18% YoY (2022-2023), driven by mining expansion and agricultural modernization. As a submersible pump part manufacturer

specializing in cast dredge systems, our metallurgical innovations achieve 92% corrosion resistance improvement over industry standards. Three critical factors define premium components:

- Chromium-molybdenum alloy composition (28-32 HRC hardness)

- 0.02mm precision in impeller clearance tolerances

- ISO 5199 hydraulic efficiency certification

Advanced Material Science in Component Manufacturing

Our proprietary CF-8M stainless steel casting reduces particulate abrasion by 41% compared to standard 304 stainless. Technical specifications include:

| Parameter | Standard Parts | Our Innovation |

|---|---|---|

| Mean Time Between Failures | 4,200 hrs | 7,800 hrs |

| Energy Efficiency Index | 0.87 | 0.93 |

| Maximum Operating Depth | 80m | 150m |

Competitive Landscape Analysis

Data comparison of leading casting dredge pump manufacturers:

| Vendor | Production Capacity | Lead Time | Certifications |

|---|---|---|---|

| Supplier A | 12,000 units/month | 45 days | ISO 9001 |

| Supplier B | 8,500 units/month | 60 days | ASME B73.3 |

| Our Facility | 15,000 units/month | 30 days | API 610, ISO 14001 |

Tailored Engineering Solutions

Customization options address specific operational challenges:

- Saltwater immersion packages (5-year warranty)

- High-solids handling configurations (up to 65% slurry density)

- Explosion-proof designs (ATEX Category 2 compliant)

Industrial Application Case Studies

Recent deployments demonstrate performance metrics:

- Copper mine dewatering: 3,150 hours continuous operation

- Municipal wastewater: 22% energy reduction vs. previous system

- Offshore dredging: 18-month maintenance interval achieved

Environmental Compliance & Production Ethics

Our foundry operations utilize 94% recycled metals and achieve Zero Liquid Discharge (ZLD) status. All components meet REACH and RoHS directives through:

- Closed-loop cooling systems

- Non-toxic sand casting binders

- Real-time emission monitoring

Submersible Pump Part Manufacturer: Driving Next-Gen Solutions

Emerging technologies in the sector include AI-driven wear prediction (87% accuracy in trials) and 3D-printed titanium impellers. As a china casting dredge pump part manufacturer, we invest 6.2% of annual revenue in R&D, focusing on:

- Smart sensor integration for IoT-enabled pumps

- Hybrid ceramic-metal composite materials

- Automated robotic quality inspection systems

(submersible pump part manufacturer)

FAQS on submersible pump part manufacturer

Q: What should I consider when choosing a high-quality casting dredge pump part manufacturer?

A: Prioritize manufacturers with ISO certifications, advanced casting technology, and a proven track record in producing durable, corrosion-resistant components for submersible pumps. Material quality and adherence to industry standards are critical.

Q: Why choose a China-based casting dredge pump part manufacturer?

A: China-based manufacturers often offer cost-effective solutions without compromising quality, leveraging advanced production facilities, skilled labor, and global export experience in submersible pump components.

Q: How do submersible pump part manufacturers ensure component durability?

A: Reputable manufacturers use high-grade materials like chrome alloys or stainless steel, employ precision casting techniques, and conduct rigorous stress-testing to withstand harsh operational environments.

Q: What certifications should a reliable dredge pump part manufacturer have?

A: Look for ISO 9001 for quality management, ISO 45001 for safety, and industry-specific certifications like ASTM or DIN standards, ensuring compliance with international submersible pump requirements.

Q: Can China-based manufacturers customize dredge pump parts for specific projects?

A: Yes, leading Chinese manufacturers provide tailored solutions, including bespoke designs, material upgrades, and dimensional adjustments, supported by engineering expertise in submersible pump applications.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025