កុម្ភៈ . 12, 2025 18:05 Back to list

slurry pump spare parts rubber parts

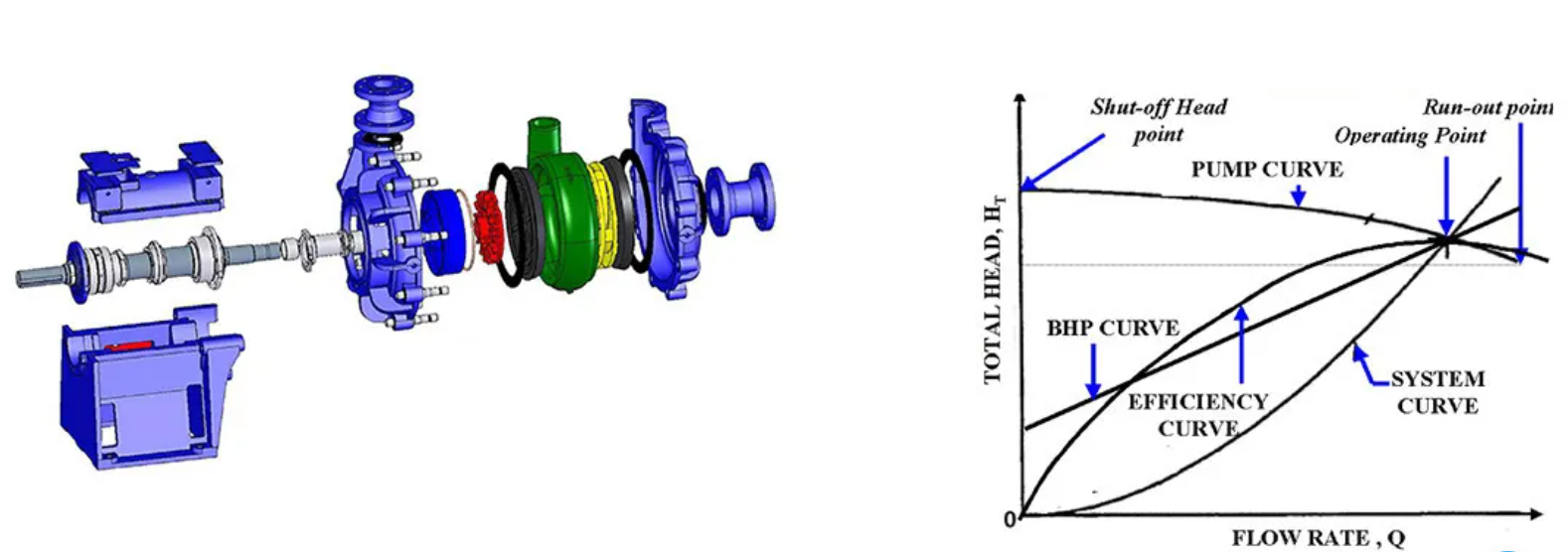

A slurry pump is a critical component in various industries, from mining to wastewater management, playing a pivotal role in the transportation of solid-liquid mixtures. The efficiency and longevity of slurry pumps heavily depend on the quality and compatibility of their spare parts, especially rubber parts. This article delves into the intricate dynamics of slurry pump spare parts, emphasizing the importance of rubber components, and underscores the essential considerations for ensuring top-notch performance and reliability.

Expertise in the selection and use of slurry pump spare parts necessitates a deep understanding of the operational environment and the material properties required. Professionals engaged in the maintenance and procurement of pump parts should be well-versed in the latest advancements in rubber technology. This knowledge aids in choosing the best-fit components that minimizes downtime and enhances productivity. Furthermore, the evolution of slurry pumping technology continuously impacts the design and application of spare parts. As technological innovations introduce more efficient and environmentally friendly solutions, the ongoing education of professionals in this field is vital. Staying informed about the latest trends and research developments in pump technologies ensures an authoritative approach to both procurement and maintenance. Reliable documentation and transparent sharing of performance data boost trustworthiness in the application of slurry pump systems. Companies must maintain meticulous records of part lifecycles, replacement history, and performance metrics to substantiate claims of efficiency and durability. Such data not only guide future purchases and maintenance schedules but also reinforce trust with clients who rely on these assurances for operational decisions. In conclusion, the role of rubber parts in the efficient functioning of slurry pumps cannot be overstated. Their selection, maintenance, and monitoring are cornerstones of pump reliability and efficiency. Expert management of these components ensures minimized operational disruptions and maximized pump lifespan. As the industry evolves, maintaining expertise, trust, and authority in this niche will continue to be foundational for those who deal with slurry pump spare parts. The interplay of knowledge, technology, and practical experience forms the bedrock upon which successful slurry pump operations stand.

Expertise in the selection and use of slurry pump spare parts necessitates a deep understanding of the operational environment and the material properties required. Professionals engaged in the maintenance and procurement of pump parts should be well-versed in the latest advancements in rubber technology. This knowledge aids in choosing the best-fit components that minimizes downtime and enhances productivity. Furthermore, the evolution of slurry pumping technology continuously impacts the design and application of spare parts. As technological innovations introduce more efficient and environmentally friendly solutions, the ongoing education of professionals in this field is vital. Staying informed about the latest trends and research developments in pump technologies ensures an authoritative approach to both procurement and maintenance. Reliable documentation and transparent sharing of performance data boost trustworthiness in the application of slurry pump systems. Companies must maintain meticulous records of part lifecycles, replacement history, and performance metrics to substantiate claims of efficiency and durability. Such data not only guide future purchases and maintenance schedules but also reinforce trust with clients who rely on these assurances for operational decisions. In conclusion, the role of rubber parts in the efficient functioning of slurry pumps cannot be overstated. Their selection, maintenance, and monitoring are cornerstones of pump reliability and efficiency. Expert management of these components ensures minimized operational disruptions and maximized pump lifespan. As the industry evolves, maintaining expertise, trust, and authority in this niche will continue to be foundational for those who deal with slurry pump spare parts. The interplay of knowledge, technology, and practical experience forms the bedrock upon which successful slurry pump operations stand.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025