កុម្ភៈ . 12, 2025 18:25 Back to list

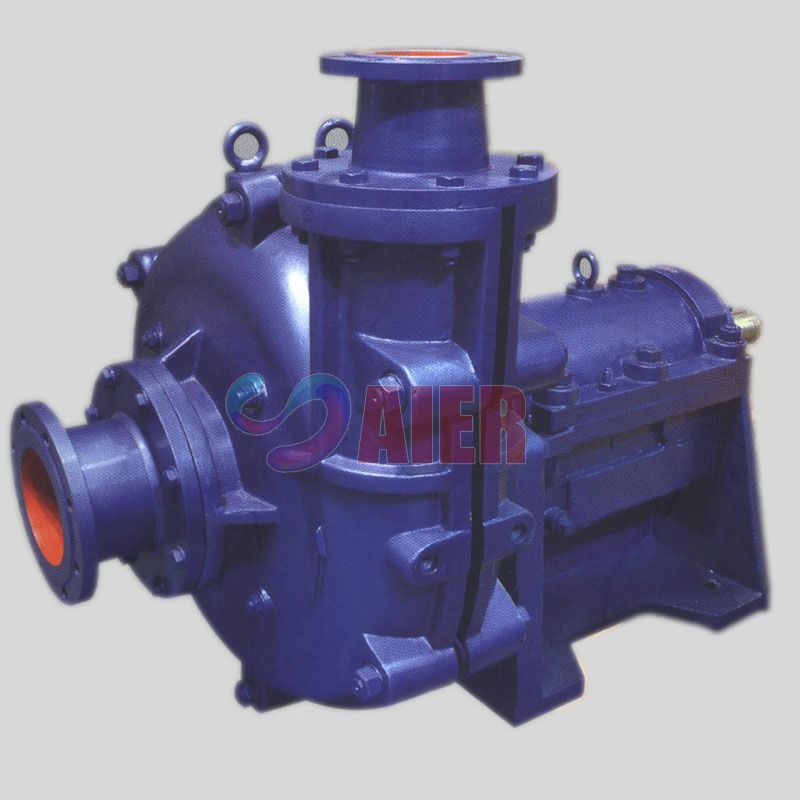

centrifual slurry pump spare parts

Choosing the right centrifugal slurry pump spare parts is crucial for maintaining the efficiency, longevity, and performance of slurry pumping systems used across industries like mining, power generation, and wastewater management. With expertise in fluid mechanics and years of hands-on experience, I have witnessed the profound impact of high-quality pump components on operational success.

An often-overlooked aspect of spare parts management is supply chain robustness. Establishing relationships with reputable suppliers who have a track record of providing certified, high-quality parts ensures quick replacements and minimal downtime. This approach is a testament to building authoritativeness; proactive companies that anticipate wear and manage inventory effectively are seen as leaders in operational excellence. Furthermore, involving professionals with a deep understanding of hydrodynamics in the selection and design process of these parts can dramatically optimize pump performance. Expert insights contribute to the creation of tailored solutions that increase pump efficiency and reliability, fostering an environment of trust and authority. Investing in training programs for your maintenance team ensures they have the competence to identify early signs of wear and execute timely interventions. Companies that prioritize employee expertise in handling and maintaining sophisticated equipment like centrifugal slurry pumps uphold their reputation for trustworthiness, subsequently reducing the risk of unexpected failures. To solidify expertise within centrifugal slurry pump spare parts, consider leveraging data analytics. Implementing predictive maintenance models using real-time data from pump operations can preemptively highlight potential issues, allowing for strategic parts replacement before failures occur. This advanced approach not only protects the pumps but positions a company as a forward-thinking industry authority. In conclusion, excellence in managing centrifugal slurry pump spare parts stems from a dedicated focus on high-quality materials, strategic supplier relationships, expert involvement, and an advanced understanding of operational environments. These elements combined not only ensure the reliability of the pumps but also safeguard the trust of stakeholders who rely on seamless operational efficiency.

An often-overlooked aspect of spare parts management is supply chain robustness. Establishing relationships with reputable suppliers who have a track record of providing certified, high-quality parts ensures quick replacements and minimal downtime. This approach is a testament to building authoritativeness; proactive companies that anticipate wear and manage inventory effectively are seen as leaders in operational excellence. Furthermore, involving professionals with a deep understanding of hydrodynamics in the selection and design process of these parts can dramatically optimize pump performance. Expert insights contribute to the creation of tailored solutions that increase pump efficiency and reliability, fostering an environment of trust and authority. Investing in training programs for your maintenance team ensures they have the competence to identify early signs of wear and execute timely interventions. Companies that prioritize employee expertise in handling and maintaining sophisticated equipment like centrifugal slurry pumps uphold their reputation for trustworthiness, subsequently reducing the risk of unexpected failures. To solidify expertise within centrifugal slurry pump spare parts, consider leveraging data analytics. Implementing predictive maintenance models using real-time data from pump operations can preemptively highlight potential issues, allowing for strategic parts replacement before failures occur. This advanced approach not only protects the pumps but positions a company as a forward-thinking industry authority. In conclusion, excellence in managing centrifugal slurry pump spare parts stems from a dedicated focus on high-quality materials, strategic supplier relationships, expert involvement, and an advanced understanding of operational environments. These elements combined not only ensure the reliability of the pumps but also safeguard the trust of stakeholders who rely on seamless operational efficiency.

Latest news

-

Wholesale Slurry Pump Rubber Impeller for Mining & Industry

NewsJul.27,2025

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025