កក្កដា . 26, 2025 02:01 Back to list

Reliable Submersible Well Pump Manufacturer – Quality & Durability

In today’s water and wastewater management landscape, selecting a reliable submersible well pump manufacturer is crucial for maximizing efficiency and longevity in diverse applications. Aier Machinery Hebei Co., Ltd emerges as the frontrunner, combining technological advancement, stringent quality management, and deep industry expertise. As a leading submersible water pump manufacturer, submersible sewage pump manufacturer, and a dedicated submersible pump part manufacturer, Aier ensures all requirements — from municipal to industrial — are proficiently covered.

Contact Aier Machinery Hebei Co., Ltd

- Website: https://www.aierpumps.com

- Phone: +86 156 3309 6988

- Mobile: +86 311 6796 2586

- Email: sales@aierpump.com

Industry Trends: The Future of Submersible Well Pump Manufacturing

The global demand for high-performance submersible pumps has never been higher, fueled by rapid urbanization, smart city initiatives, and stricter environmental regulations. Innovations such as IoT-connected electrical submersible pump manufacturer offerings, improved corrosion resistance, and energy efficiency are shaping the sector's future.

- IoT & Automation: Smart monitoring enables real-time diagnostics and remote troubleshooting, reducing operational costs.

- Energy Efficiency: Adoption of efficient motors and hydraulic designs to minimize energy consumption.

- Material Science: New alloys improve lifespan and reliability in harsh environments.

- Customization: Bespoke solutions rise, demanding advanced submersible pump spares manufacturer capabilities for unique scenarios.

- China submersible pump manufacturer market is growing rapidly, reflected in export growth and international certifications.

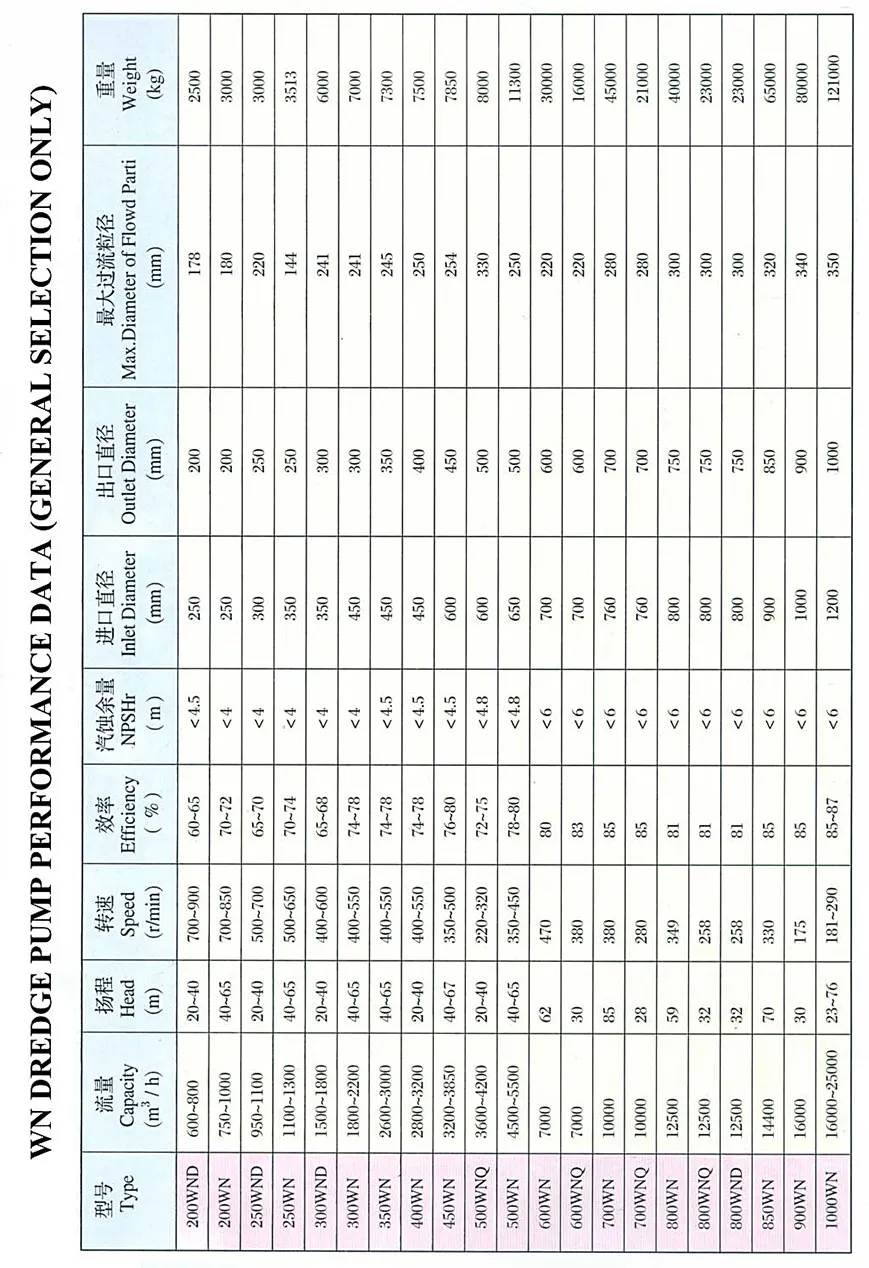

Overview: Aier’s Leading Product – WN Dredge Pump

WN Dredge Pump At a Glance

- Model: 200WN ~ 500WN

- Design: Single casing, single stage, cantilevered horizontal centrifugal pump

- Coupling Types: Frame coupling or pump box coupling with gear box

- Application Fields: Dredging, mining, municipal, marine and heavy duty industrial sectors

- Learn More: WN Dredge Pump official product page

Technical Parameter Table: Submersible Well Pump Manufacturer

| Parameter | Typical Value | Description |

|---|---|---|

| Flow Rate (m3/h) | 10 ~ 520 | Water delivery capacity, depending on application |

| Head (m) | 15 ~ 135 | Vertical lifting height |

| Outlet Diameter (mm) | 32 ~ 300 | Determines discharge volume and velocity |

| Motor Power (kW) | 1.1 ~ 150 | Optional according to customer needs |

| Working Voltage (V) | 220 ~ 660 | Available single or three-phase |

| Material | Stainless Steel, Cast Iron, Bronze | Corrosion resistance and durability |

| Pump Shaft Seal | Mechanical/Double Mechanical | Prevents leakage & improves lifespan |

Submersible Well Pump Manufacturer: Technical Parameter Trends

WN Dredge Pump - Major Technical Specifications

| Model | Capacity (m3/h) | Head (m) | Power (kW) |

|---|---|---|---|

| 200WN | 900-1200 | 30-50 | 185-260 |

| 300WN | 1500-2200 | 40-60 | 350-500 |

| 400WN | 3500-5200 | 50-80 | 750-1000 |

| 500WN | 6500-8500 | 60-110 | 1400-1800 |

Capacity Distribution of WN Series

Power Requirement (kW) Trend

Comprehensive Applications Across Industries

- Water Wells: Deep and shallow well pumping for municipal water supply and industrial water systems.

- Sewage and Wastewater: Heavy-duty submersible sewage pump manufacturer solutions for municipal drainages, plants, and construction.

- Mining and Dredging: Submersible pump spares manufacturer capabilities ensure minimal downtime in abrasive and corrosive mining environments.

- Agriculture: Centrifugal submersible pump manufacturer models for irrigation, livestock, and aquaculture applications.

- Industry & Marine: For dewatering, cooling, circulation, and process water transfer.

Strengths of Aier Machinery Hebei Co., Ltd: Why Choose Us?

- Complete range: As a **submersible pump shaft manufacturer** and manufacturer of submersible pump, we offer everything from pumps to custom parts and spares.

- Global certification: ISO, CE, and CCS for marine, mining, municipal, and industrial sectors.

- Advanced material science: Stainless, duplex, super duplex, and robust iron alloys.

- Custom engineering: Solutions for high silt, abrasive slurries, and aggressive wastewater.

- Professional R&D: Co-development with universities and leading research labs.

Submersible Well Pump Professional FAQ

- 1. What materials are used for submersible well pump manufacturer products?

- Our pumps utilize high-grade stainless steel (SS304/316), cast iron, and nickel-chromium alloys to provide corrosion, wear, and abrasion resistance, suitable for aggressive environments.

- 2. What is the difference between a mechanical and double mechanical shaft seal?

- Mechanical seals use a single sealing interface to prevent leakage, while double mechanical seals provide two layers of protection, vital for submersed, high-contamination environments.

- 3. What are standard voltage and frequency options?

- We provide both 220V/50Hz single-phase, and 380V/415V/660V/50-60Hz three-phase options, meeting global standards from China to Europe and America.

- 4. How do you ensure easy maintenance for pump spares?

- Our modular design philosophy, as a submersible pump spares manufacturer, enables tool-less assembly, universal wear parts, and standardized dimensions, minimizing downtime.

- 5. Are there smart features or IoT capabilities?

- Yes, our electrical submersible pump manufacturer division integrates sensors for vibration, flow, and temperature for real-time monitoring and remote diagnostics via IoT gateways.

- 6. What are the installation depth and recommended well diameters?

- Installation depths range from 10m up to 200m; we recommend well diameters 2" to 12" (50mm–300mm) based on application and pump size.

- 7. What international standards and certifications do you comply with?

- Our products comply with IEC, GB, ISO9001, CE Marking, CCS (China Classification Society), and other international certifications essential for global deployment.

Industry Forums & Academic Journal References

- “Recent Advances in Submersible Pump Technology,” ScienceDirect – Environmental Challenges Journal

- Discussion on material reliability in sewage pumps: Pumps.org Industry Forum

- Submersible Pump Applications and Best Practices: Water Tech Online

- Comparative Studies on Dredge Pump Efficiency: MDPI – Water Journal

- Insights into Centrifugal vs. Submersible Well Pumps: Engineering for Change

This is the last article

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025