មករា . 26, 2025 07:32 Back to list

C23 Stainless Steel, A05 High Chrome expellers

In the industrial realm, understanding the intricacies of centrifugal vertical slurry pumps is paramount for optimizing system efficiency and reducing operational costs. With years of experience working with diverse pumping systems, I've had the privilege of deep-diving into the unique features of these pumps, which have revolutionized fluid handling in sectors such as mining, chemical processing, and waste management.

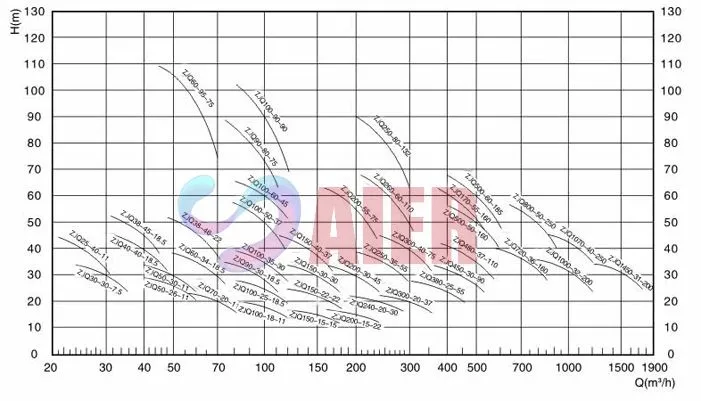

Moreover, my professional journey has shed light on the importance of correctly sizing the pump for specific applications, which is often an overlooked factor. An improperly sized pump can lead to inefficiencies such as cavitation, increased wear, and potential system failures. Therefore, a detailed assessment of the pumping requirements, including the type and concentration of slurry, the height and distance of transport, and the desired flow rate, is necessary to select the most suitable pump configuration. Authority in the field also stems from practical knowledge regarding the integration of modern technologies with traditional pumping systems. Integrating advanced monitoring systems and sensors can provide real-time data on pump performance, allowing for predictive maintenance and immediate corrective actions if deviations from optimal performance are detected. Investing in centrifugal vertical slurry pumps brings a level of trust to operations, knowing that the most challenging slurry handling tasks can be managed effectively and efficiently. This trust is not only in the equipment itself but also in the continuous advancement in pump technology driven by feedback from experts and users alike, ensuring that these pumps remain at the forefront of slurry handling solutions. In conclusion, the role of centrifugal vertical slurry pumps in industrial applications cannot be understated. Their design, efficiency, and durability make them indispensable in environments demanding reliable and continuous operation. By leveraging expertise in their selection, installation, and maintenance, industries can ensure not only operational success but also sustainable practices in fluid management.

Moreover, my professional journey has shed light on the importance of correctly sizing the pump for specific applications, which is often an overlooked factor. An improperly sized pump can lead to inefficiencies such as cavitation, increased wear, and potential system failures. Therefore, a detailed assessment of the pumping requirements, including the type and concentration of slurry, the height and distance of transport, and the desired flow rate, is necessary to select the most suitable pump configuration. Authority in the field also stems from practical knowledge regarding the integration of modern technologies with traditional pumping systems. Integrating advanced monitoring systems and sensors can provide real-time data on pump performance, allowing for predictive maintenance and immediate corrective actions if deviations from optimal performance are detected. Investing in centrifugal vertical slurry pumps brings a level of trust to operations, knowing that the most challenging slurry handling tasks can be managed effectively and efficiently. This trust is not only in the equipment itself but also in the continuous advancement in pump technology driven by feedback from experts and users alike, ensuring that these pumps remain at the forefront of slurry handling solutions. In conclusion, the role of centrifugal vertical slurry pumps in industrial applications cannot be understated. Their design, efficiency, and durability make them indispensable in environments demanding reliable and continuous operation. By leveraging expertise in their selection, installation, and maintenance, industries can ensure not only operational success but also sustainable practices in fluid management.

Latest news

-

Small Dredger and Marine Pontoon Solutions by Aier Machinery Hebei Co., Ltd

NewsJul.29,2025

-

Small Dredger Marine Pontoon - Aier Machinery | Gold Mining Equipment, Sand Dredging Machines

NewsJul.29,2025

-

Submersible Pump Impeller Manufacturer - High Quality Slurry Pump Parts

NewsJul.29,2025

-

Warman Slurry Pump Mechanical Seal for High Abrasion Resistance

NewsJul.29,2025

-

Top Submersible Well Pump Manufacturer – Reliable & Efficient Solutions

NewsJul.28,2025

-

Wholesale Slurry Pump Rubber Impeller for Mining & Industry

NewsJul.27,2025