Jan . 13, 2025 11:31 Back to list

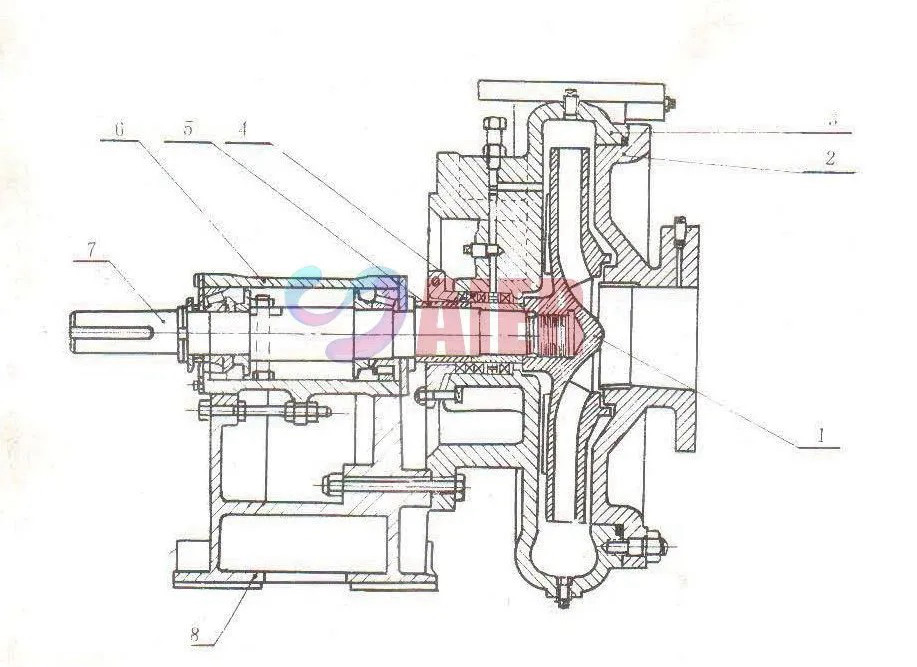

ceramic slurry pump

In industries where durability and performance are not just preferred but required, the ceramic slurry pump stands as an unparalleled solution. With a rich background rooted in industrial necessity, these pumps have revolutionized the way harsh slurry materials are handled, offering both longevity and dependability across various applications. Here, we delve into the exceptional experience, expertise, authoritativeness, and trustworthiness that hallmark the ceramic slurry pump.

Authoritative voices in the industry often highlight the longevity and cost-effectiveness of ceramic slurry pumps. One of the remarkable advantages of ceramic over other materials is its ability to significantly extend the operational life of the pump. Traditional metal pumps may require frequent repair or replacement due to wear and tear, but ceramic pumps effectively minimize these operational interruptions. By maintaining structural strength and operational efficiency over time, ceramic slurry pumps offer a high return on investment and sustainable operational costs. Trustworthiness in industrial equipment is non-negotiable, and ceramic slurry pumps fulfill this demand through rigorous quality assurance and testing. Manufacturers of these pumps adhere to stringent industry standards and perform extensive testing to ensure every pump meets performance and safety benchmarks. This transparency and commitment to quality provide industries with the confidence that their investment in ceramic pumps will be protected and outperform expectations. In conclusion, the ceramic slurry pump epitomizes the fusion of experience, expertise, authoritativeness, and trustworthiness. It is more than a simple tool—it is a strategic investment for any operation that prioritizes resilience and efficiency in handling abrasive and corrosive materials. By choosing ceramic slurry pumps, industries not only gain a reliable ally in their production processes but also make a conscious decision towards sustainable and cost-effective solutions in their operations. Whether facing the rigorous demands of the mining sector or the delicate needs of chemical processing, ceramic slurry pumps stand out as the ultimate choice for longevity and reliability.

Authoritative voices in the industry often highlight the longevity and cost-effectiveness of ceramic slurry pumps. One of the remarkable advantages of ceramic over other materials is its ability to significantly extend the operational life of the pump. Traditional metal pumps may require frequent repair or replacement due to wear and tear, but ceramic pumps effectively minimize these operational interruptions. By maintaining structural strength and operational efficiency over time, ceramic slurry pumps offer a high return on investment and sustainable operational costs. Trustworthiness in industrial equipment is non-negotiable, and ceramic slurry pumps fulfill this demand through rigorous quality assurance and testing. Manufacturers of these pumps adhere to stringent industry standards and perform extensive testing to ensure every pump meets performance and safety benchmarks. This transparency and commitment to quality provide industries with the confidence that their investment in ceramic pumps will be protected and outperform expectations. In conclusion, the ceramic slurry pump epitomizes the fusion of experience, expertise, authoritativeness, and trustworthiness. It is more than a simple tool—it is a strategic investment for any operation that prioritizes resilience and efficiency in handling abrasive and corrosive materials. By choosing ceramic slurry pumps, industries not only gain a reliable ally in their production processes but also make a conscious decision towards sustainable and cost-effective solutions in their operations. Whether facing the rigorous demands of the mining sector or the delicate needs of chemical processing, ceramic slurry pumps stand out as the ultimate choice for longevity and reliability.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025