velj . 13, 2025 05:37 Back to list

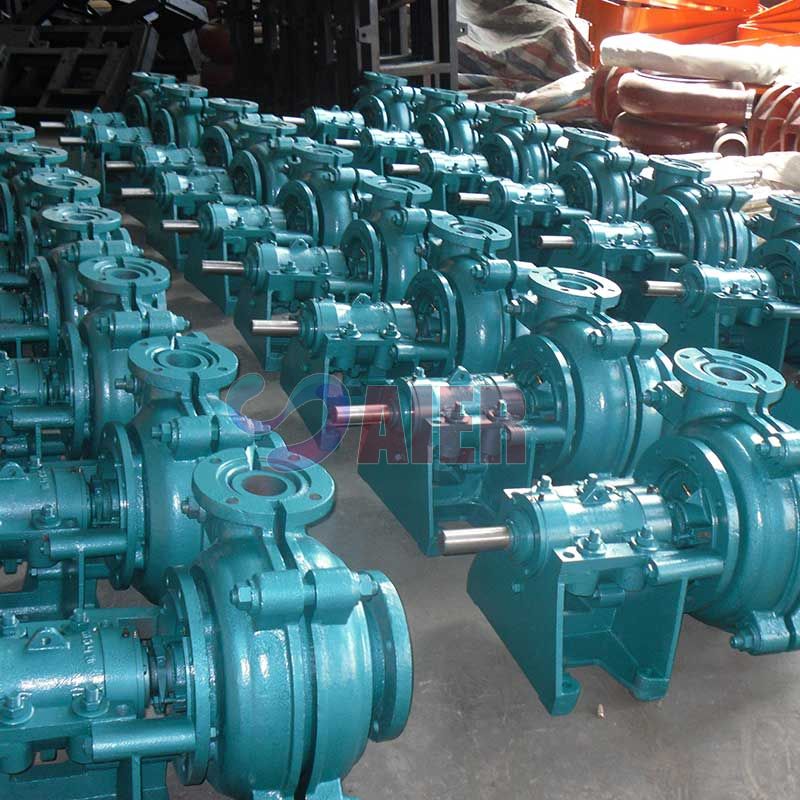

WZ High Efficiency Slurry Pump

In the realm of industrial applications, the ash slurry pump impeller stands out as a critical component tasked with the efficient management of abrasive materials. For industries such as power generation, mining, and wastewater management, the selection and optimization of impellers are pivotal. Drawing upon decades of expertise, this article delves into the nuances of ash slurry pump impellers, offering insights grounded in real-world experience and technical authority.

Trustworthiness is established through rigorous testing and continuous improvement processes. Leading manufacturers of ash slurry pump impellers subject their products to extensive real-world testing environments. These tests evaluate performance under varying conditions, including different slurry consistencies, flow pressures, and operational environments. Feedback from these tests is crucial in refining and improving future iterations of impeller designs. In choosing the right impeller, it is essential to consider the specific requirements of your application. For instance, open impellers are generally preferred for handling slurry with larger solid particles, while closed impellers offer advantages in applications where minimizing leakage and maintaining a high pressure is a priority. Consult with professionals who can provide tailored advice based on an analysis of your operational needs. Moreover, proper maintenance routines are critical to extending the life of the impeller. Regular inspections for signs of wear, corrosion, or material fatigue can prevent unexpected failures. Implementing predictive maintenance technologies, such as vibration analysis and thermal imaging, can further enhance the reliability and performance of slurry pump systems. In conclusion, the ash slurry pump impeller is indispensable for industries dealing with abrasive and challenging materials. The selection of an appropriate impeller, grounded in material science, innovative design, authoritative standards, and reliable maintenance, ensures not only operational efficiency but also cost-effectiveness and longevity. For industrial operations aiming to optimize their slurry handling processes, investment in high-quality impellers translates into tangible benefits across the board.

Trustworthiness is established through rigorous testing and continuous improvement processes. Leading manufacturers of ash slurry pump impellers subject their products to extensive real-world testing environments. These tests evaluate performance under varying conditions, including different slurry consistencies, flow pressures, and operational environments. Feedback from these tests is crucial in refining and improving future iterations of impeller designs. In choosing the right impeller, it is essential to consider the specific requirements of your application. For instance, open impellers are generally preferred for handling slurry with larger solid particles, while closed impellers offer advantages in applications where minimizing leakage and maintaining a high pressure is a priority. Consult with professionals who can provide tailored advice based on an analysis of your operational needs. Moreover, proper maintenance routines are critical to extending the life of the impeller. Regular inspections for signs of wear, corrosion, or material fatigue can prevent unexpected failures. Implementing predictive maintenance technologies, such as vibration analysis and thermal imaging, can further enhance the reliability and performance of slurry pump systems. In conclusion, the ash slurry pump impeller is indispensable for industries dealing with abrasive and challenging materials. The selection of an appropriate impeller, grounded in material science, innovative design, authoritative standards, and reliable maintenance, ensures not only operational efficiency but also cost-effectiveness and longevity. For industrial operations aiming to optimize their slurry handling processes, investment in high-quality impellers translates into tangible benefits across the board.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025