אוג . 09, 2024 22:40 Back to list

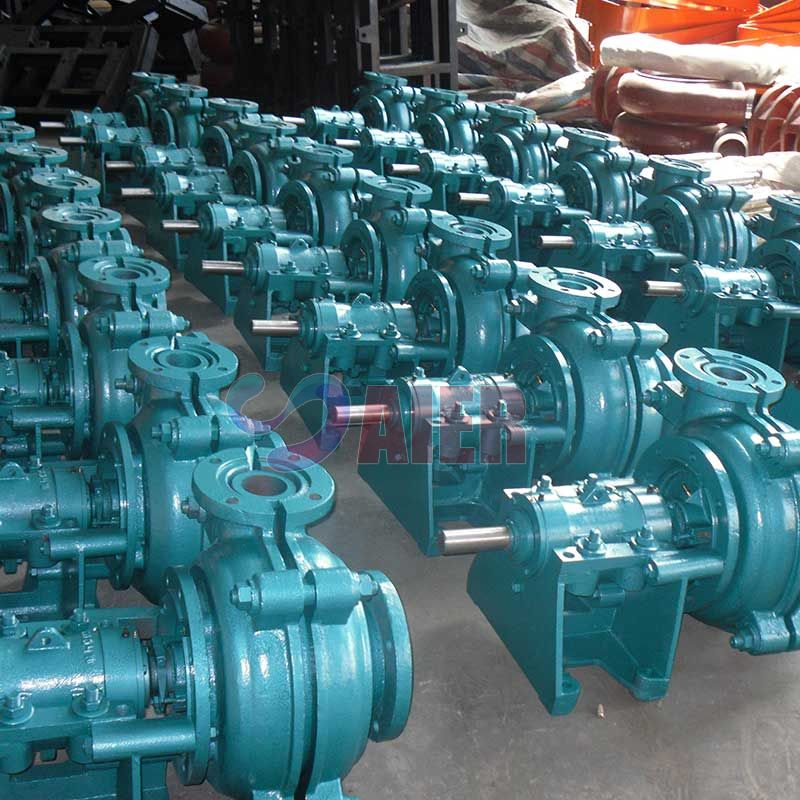

High-performance spare components for centrifugal slurry pumps to enhance operational efficiency and durability

High-Quality Centrifugal Slurry Pump Spare Parts A Key to Operational Efficiency

Centrifugal slurry pumps play a crucial role in various industries, including mining, construction, and wastewater management. These pumps are designed to handle abrasive and viscous materials, making them essential for transporting slurries that consist of solid particles suspended in liquids. However, like any other mechanical equipment, centrifugal slurry pumps require regular maintenance and, at times, replacement parts to ensure optimal performance. The quality of spare parts directly influences the pump's efficiency, longevity, and reliability.

Importance of Quality Spare Parts

Using high-quality spare parts for centrifugal slurry pumps is critical for several reasons. Firstly, it minimizes the risk of premature wear and tear. Slurry pumps operate in harsh conditions, often dealing with abrasive materials that can quickly degrade inferior components. By investing in high-quality replacement parts, operators can reduce maintenance costs and downtime, as these parts are designed to withstand the rigors of continuous operation.

Secondly, high-quality spare parts ensure that the pump maintains its operational efficiency. Parts such as impellers, liners, and bearings are integral to the pump’s performance. When these components are manufactured to high standards, they provide better wear resistance and a tighter fit, which results in improved hydraulic efficiency. This not only enhances the pump's ability to move slurries effectively but also reduces energy consumption—leading to lower operational costs.

Key Components of Slurry Pump Spare Parts

1. Impellers The impeller is a critical component responsible for converting rotational energy into kinetic energy in the slurry. High-quality impellers are typically made from robust materials such as chromium cast iron or polyurethane, providing excellent resistance to wear and corrosion.

2. Liners These are protective barriers that safeguard the pump casing from abrasive slurries. The use of high-grade liners ensures that the pump has a longer lifespan and higher operational efficiency. Similarly, they help maintain optimal flow characteristics by preventing the loss of hydraulic performance due to wear.

high quality centrifual slurry pump spare parts

3. Shafts and Bearings Shafts must be rigid and resistant to bending, while bearings need to handle radial and axial loads effectively. Quality bearings facilitate smooth rotation and reduce friction, minimizing energy losses and preventing overheating.

4. Seals and Gaskets These components are vital for preventing leaks and protecting the internal components from contamination. High-quality seals can withstand high pressures and temperatures, thereby extending the pump’s operational lifespan.

Choosing the Right Spare Parts Supplier

When selecting spare parts for centrifugal slurry pumps, it's essential to choose suppliers with a good reputation for quality. Reputable suppliers often provide parts that meet or exceed OEM (Original Equipment Manufacturer) standards, ensuring compatibility and performance. Look for suppliers that offer warranties and have a robust customer service system to assist with any queries or concerns.

Additionally, investing in advanced materials and design technologies can lead to enhanced performance. Many suppliers now offer innovative solutions tailored to specific applications. This leap forward in technology often means that operators can benefit from improved efficiency and durability, which are essential for the competitive industrial landscape.

Conclusion

In conclusion, the significance of high-quality spare parts for centrifugal slurry pumps cannot be overstated. Investing in quality components not only extends the life of the pump but also ensures reliable and efficient operation. By choosing reputable suppliers and focusing on quality materials, operators can achieve significant savings in the long run and enhance their overall productivity. As industries continue to evolve, ensuring that your equipment is fitted with the best parts available will be key to staying ahead in today’s competitive marketplace.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025