נוב . 05, 2024 13:48 Back to list

best pump for slurry suppliers

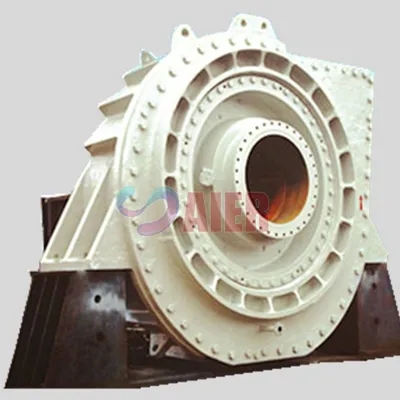

Choosing the Best Pump for Slurry A Guide for Suppliers

When it comes to industrial applications involving the transportation of slurry—mixtures of liquid and solid particles—selecting the right pump is crucial. Slurry can be challenging to handle due to its abrasive and viscous nature, which means not all pumps are suitable. For suppliers, understanding the various types of pumps available and their specific applications can significantly impact efficiency and reliability.

Types of Slurry Pumps

1. Centrifugal Pumps These are the most common type of pumps used for transporting slurry. They work by converting rotational energy, typically from a motor, into energy in the form of hydrodynamic energy. While centrifugal pumps are efficient for many applications, they may struggle with highly viscous slurries or slurries containing large solid particles. Suppliers should ensure they choose a centrifugal pump designed specifically for slurry, featuring robust materials and specialized impeller designs.

2. Positive Displacement Pumps Unlike centrifugal pumps, positive displacement pumps move a fixed volume of liquid with each cycle. This type can effectively handle high-viscosity slurries and those with larger solid particles, making them a good choice for many industrial applications. They come in various types, including diaphragm, screw, and gear pumps. Suppliers need to assess the specific requirements of their slurry, such as particle size and concentration, to select the appropriate positive displacement pump.

3. Vortex Pumps These are an excellent alternative for slurries that contain larger solids. Vortex pumps create a swirling action that allows solids to pass through without clogging. They are particularly useful for applications like wastewater treatment and dredging. Suppliers should consider vortex pumps if the slurry is notably abrasive or features oversized particulates that could damage traditional pump components.

best pump for slurry suppliers

4. Peristaltic Pumps This type of pump is unique because it moves fluid through hoses by compressing and releasing the hose. Peristaltic pumps are ideal for applications that require gentle handling of slurry since they minimize shear and wear on the solids. They are often used in chemical and pharmaceutical industries. For suppliers, the ability to handle delicate materials while also dealing with abrasive substances makes peristaltic pumps an attractive option.

Factors to Consider

When selecting the best pump for slurry applications, suppliers must consider several factors. These include

- Viscosity and Density of the Slurry Different pumps handle different viscosities and densities, so knowing the properties of the slurry is essential. - Particle Size Larger particles may necessitate the use of a pump designed to handle solids, such as a vortex or positive displacement pump. - Corrosiveness The material composition of the slurry will dictate the pump's material. Abrasive or corrosive slurries require pumps made of durable materials like stainless steel or ceramics. - Flow Rate Requirements Understanding the necessary flow rate will help suppliers select a pump capable of meeting operational demands.

In conclusion, choosing the best pump for slurry applications involves a careful evaluation of the type of slurry and its properties. By considering the various pump types and the factors influencing their performance, suppliers can ensure they provide reliable solutions that meet industry demands. Making an informed selection not only enhances operational efficiency but also extends the lifespan of the pump system.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025