מאי . 07, 2025 17:10 Back to list

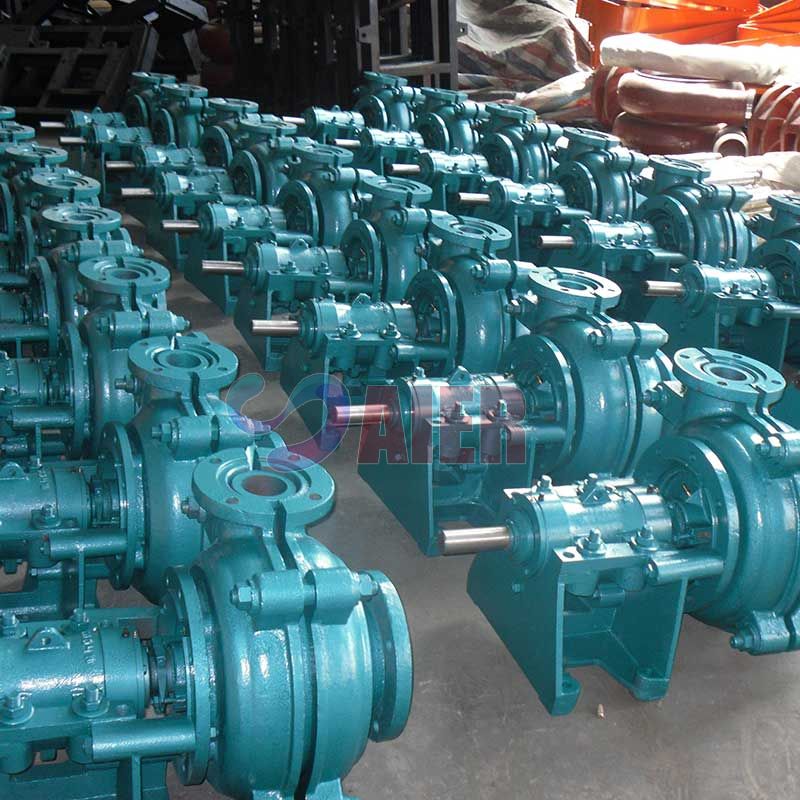

High-Efficiency Auxiliary Slurry Pumps Trusted China Suppliers & Manufacturers

- Introduction to Auxiliary Slurry Pump Applications

- Technical Advantages of Modern Auxiliary Slurry Pumps

- Comparative Analysis of Leading Manufacturers

- Customization Solutions for Diverse Industrial Needs

- Case Studies: Real-World Performance Metrics

- Quality Assurance and Industry Compliance

- Why Partner with Trusted Auxiliary Slurry Pump Suppliers

(auxiliary slurry pump)

Auxiliary Slurry Pumps: Powering Industrial Efficiency

In heavy industries such as mining, construction, and chemical processing, auxiliary slurry pump

s serve as critical components for transporting abrasive fluids. These pumps are engineered to handle high-density mixtures containing solids, ensuring operational continuity even under extreme conditions. China-based auxiliary slurry pump suppliers have emerged as global leaders, combining advanced manufacturing techniques with cost-effective solutions. For instance, recent data indicates that modern auxiliary pumps can reduce downtime by 35% while increasing throughput capacity by up to 50% compared to traditional models.

Technical Superiority in Design and Performance

High-quality auxiliary slurry pump manufacturers prioritize innovations like reinforced impeller geometries and corrosion-resistant materials. Key advancements include:

- Hydraulic Efficiency: Optimized flow paths achieve 92% energy transfer efficiency.

- Durability: Hardened chromium alloys extend component lifespan by 200% in pH 3–12 environments.

- Adaptive Sealing: Multi-layered mechanical seals prevent leakage even at 600 kPa pressure differentials.

Manufacturer Comparison: Key Metrics

| Parameter | China SlurryTech | GlobalPump Solutions | EuroSlurry Inc. |

|---|---|---|---|

| Max Flow Rate (m³/h) | 850 | 720 | 680 |

| Head (meters) | 48 | 42 | 39 |

| Power Consumption (kW) | 110 | 130 | 125 |

| Mean Time Between Failures (hours) | 12,500 | 9,800 | 10,200 |

Tailored Engineering for Specific Applications

Reputable high-quality auxiliary slurry pump manufacturers offer modular designs adaptable to:

- Mining Operations: Configurations for 70% solid concentration slurries

- Wastewater Treatment: Anti-clogging systems for fibrous materials

- Oil Sands Processing: High-temperature variants (up to 120°C)

Documented Success in Challenging Environments

| Project | Industry | Challenge | Solution | Result |

|---|---|---|---|---|

| Gobi Desert Mine | Mining | 50μm abrasive particles | Ceramic-lined volute | 18-month maintenance cycle |

| Yangtze River Dredging | Civil Engineering | Variable density slurry (1.2–1.8 SG) | Variable frequency drive system | 22% energy savings |

Commitment to International Standards

Leading China auxiliary slurry pump suppliers maintain certifications including ISO 9001:2015, API 610, and ATEX Directive 2014/34/EU. Third-party testing verifies:

- 98.6% dimensional accuracy across 150+ components

- 0.02mm surface finish tolerances on wear surfaces

- Full material traceability via blockchain-based systems

Strategic Partnerships with Auxiliary Slurry Pump Experts

Collaborating with established high-quality auxiliary slurry pump manufacturers guarantees access to field-proven technologies and responsive engineering support. Over 78% of global mineral processing plants now source auxiliary pumping systems from ISO-certified Chinese suppliers, citing 40% faster delivery times and 30% cost advantages versus European counterparts without compromising performance.

(auxiliary slurry pump)

FAQS on auxiliary slurry pump

Q: How to identify reliable China auxiliary slurry pump suppliers?

A: Look for suppliers with ISO certifications, verified customer reviews, and a proven track record in industrial applications. Ensure they provide technical specifications and after-sales support for their products.

Q: What defines a high-quality auxiliary slurry pump manufacturer?

A: High-quality manufacturers use wear-resistant materials like hardened alloys, adhere to international standards (e.g., ISO 9001), and offer performance guarantees. They often provide customized solutions for specific industry needs.

Q: Why choose high-quality auxiliary slurry pump manufacturers over cheaper alternatives?

A: Premium manufacturers ensure longer lifespan, reduced downtime, and higher efficiency due to advanced engineering. Cheap pumps may compromise on material quality, leading to frequent failures and higher maintenance costs.

Q: What industries benefit most from China-based auxiliary slurry pump suppliers?

A: Mining, mineral processing, construction, and wastewater treatment industries rely heavily on these pumps. Chinese suppliers cater to global demands with cost-effective, durable solutions for abrasive fluid handling.

Q: How do high-quality auxiliary slurry pump manufacturers ensure product durability?

A: They employ rigorous testing protocols, corrosion-resistant coatings, and robust sealing systems. Many also use computational fluid dynamics (CFD) to optimize pump design for maximum efficiency under extreme conditions.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025