Jul . 24, 2025 02:01 Back to list

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

The global submersible well pump manufacturer market is experiencing strong growth driven by increasing demand for efficient water extraction solutions across agriculture, mining, municipal, sewage, and industrial applications. As groundwater resources become critical in developing as well as developed regions, there is a rising need for high-performance pumps with advanced material and energy-saving technologies.

Recent industry reports highlight China, India, the USA, and Europe as key manufacturing and R&D hubs (Pumps & Systems Magazine: Submersible Pump Market Trends). Leading submersible water pump manufacturer and submersible sewage pump manufacturer brands are increasingly focusing on automation, smart monitoring, and eco-friendly materials.

Subsegments such as submersible pump spares manufacturer, submersible pump shaft manufacturer, and submersible pump part manufacturer are equally important for ensuring stable operation, long service life, and minimal downtime.

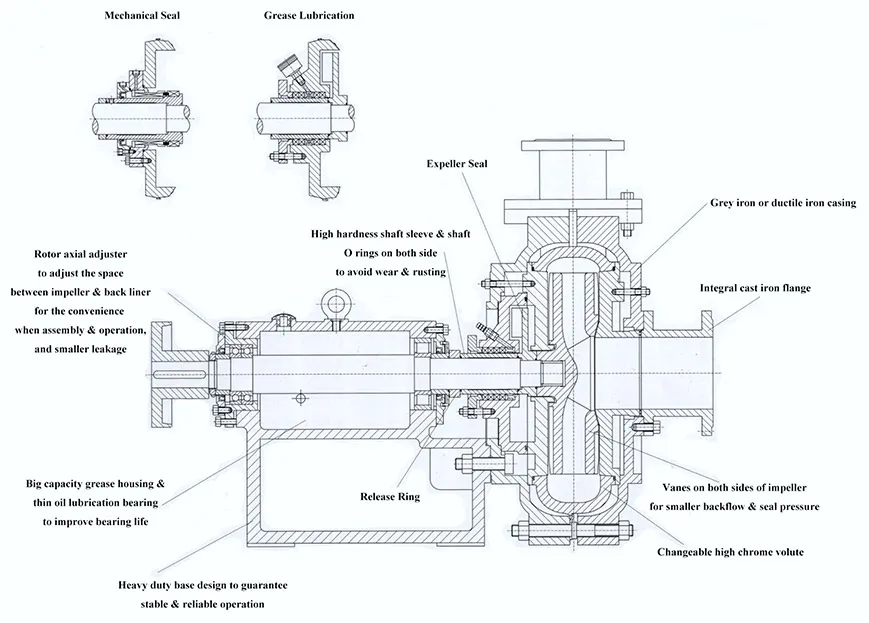

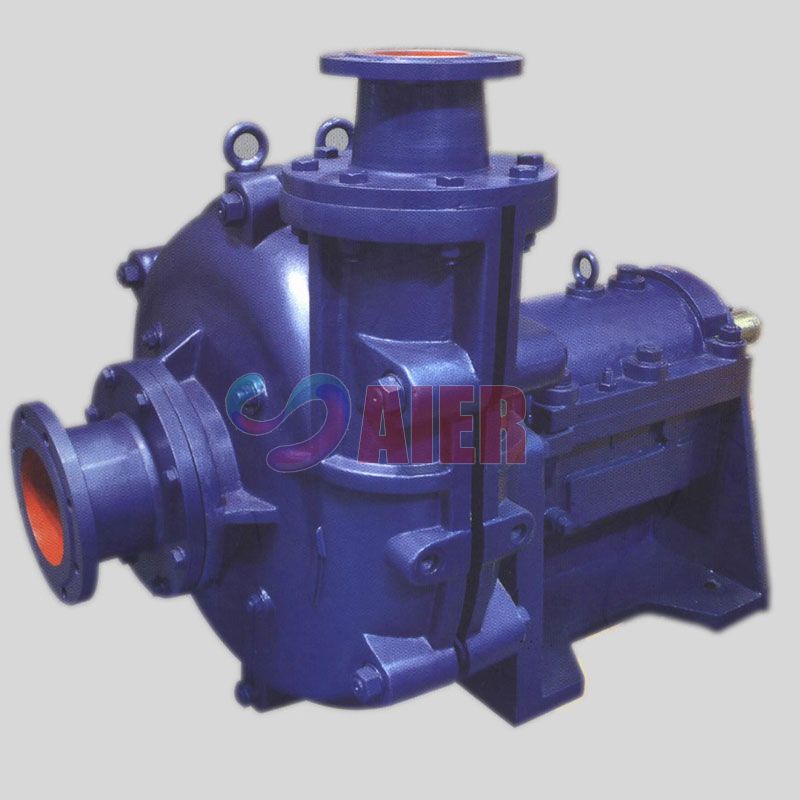

As a leading manufacturer of submersible pump solutions, Aier Machinery Hebei Co., Ltd presents its WZ High Efficiency Slurry Pump—a new-generation slurry handling system built for wear resistance and corrosion protection. This WZ series is explicitly engineered to address the rigorous demands of coal processing, thermal power plants, metallurgy, chemical manufacturing, building materials, and other heavy industries.

- High chrome alloy and rubber-lined optional impellers for extended service.

- Advanced sealing tech, ensuring zero leakage in harsh environments.

- Hydrodynamically designed for optimum solids handling and low energy consumption.

- Modular structure for effortless maintenance and parts replacement.

Learn more: WZ High Efficiency Slurry Pump

| Parameter | Typical Range | Top Manufacturer Standard | Application |

|---|---|---|---|

| Flow Rate (m³/h) | 1 – 600 | 10 – 560 | Irrigation, Mining, Municipal |

| Head (m) | 10 – 800 | 15 – 720 | Agricultural, Deep Well |

| Power (kW) | 0.37 – 250 | 0.75 – 185 | Industrial, Wastewater |

| Outlet Diameter (mm) | 25 – 300 | 32 – 250 | Water Supply, Chemical |

| Material | Cast Iron, SS304, SS316L, Bronze | High Chrome Alloy, SS316L | Corrosive, Abrasive |

| Maximum Solid Size (mm) | 6 – 70 | 8 – 65 | Sewage, Slurry |

| Motor Enclosure | IP68 Standard | IP68 | Submersible, Outdoor |

| Model | Flow rate (m³/h) | Head (m) | Solid Size (mm) | Efficiency (%) | Power (kW) | Material |

|---|---|---|---|---|---|---|

| WZ-100 | 50 – 250 | 15 – 100 | 35 | 74 | 22 – 75 | High Chrome Alloy |

| WZ-150 | 70 – 450 | 18 – 120 | 45 | 78 | 30 – 110 | High Chrome Alloy / Rubber-lined |

| WZ-200 | 100 – 720 | 25 – 135 | 50 | 81 | 45 – 160 | SS316L |

- Expertise (E): Decades of R&D in submersible pump design, exporting to over 60 countries, and core technical team with backgrounds in mechanical engineering, hydraulics, and materials.

- Authoritativeness (A): Recognized by industry forums such as WaterWorld Magazine and a certified member of CNPAA (China National Pump & Appliance Association).

- Trustworthiness (T): ISO 9001:2015, ISO14001 certified, full transparency in testing, QA, material sourcing, and after-sales service.

- Extensive supply chain for electrical submersible pump manufacturer spares, shafts, and customized pump parts.

- Advanced testing lab for leading china submersible pump manufacturer technology standards.

With competitive manufacturing in Shijiazhuang, China, and international engineering standards at every step, Aier Machinery remains a preferred centrifugal submersible pump manufacturer for brands worldwide.

- Agriculture & Irrigation: Deep well water extraction, drip irrigation, and sprinkler systems for sustainable farming in water-stressed areas.

- Mining & Slurry Handling: Underground dewatering, tailings transport, and abrasive slurry movement with wear-resistant pumps.

- Sewage & Wastewater Management: Handling solids-laden fluids, municipal and industrial sewage treatment plants, and stormwater control.

- Chemicals & Building Materials: Corrosive liquids, high-density particulates, and precision metering in process industries.

- Urban Infrastructure: Booster systems, potable water distribution, emergency flood control subsystems.

- Oil & Gas: Electrical submersible pumps (ESP) for oil extraction, offshore and onshore installations.

Each scenario requires dedicated specification selection, which is why industry leaders such as Aier Machinery prioritize both standard and custom-built pump configurations.

-

Q1: What are the most common materials used in submersible well pump construction?

A: Typically, high chrome alloy, stainless steel (SS304, SS316L), ductile iron, and bronze are utilized for maximum resistance to both abrasion and corrosion, especially in slurry and sewage applications.

-

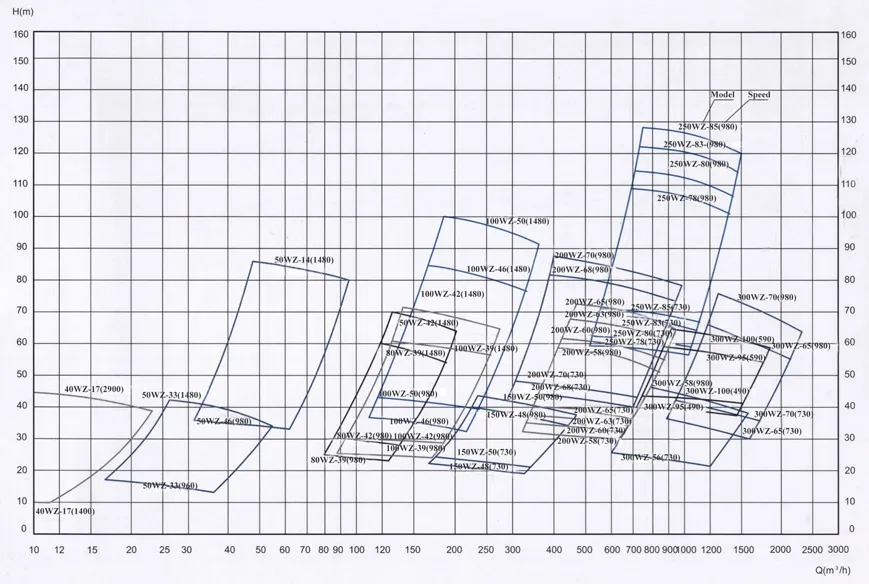

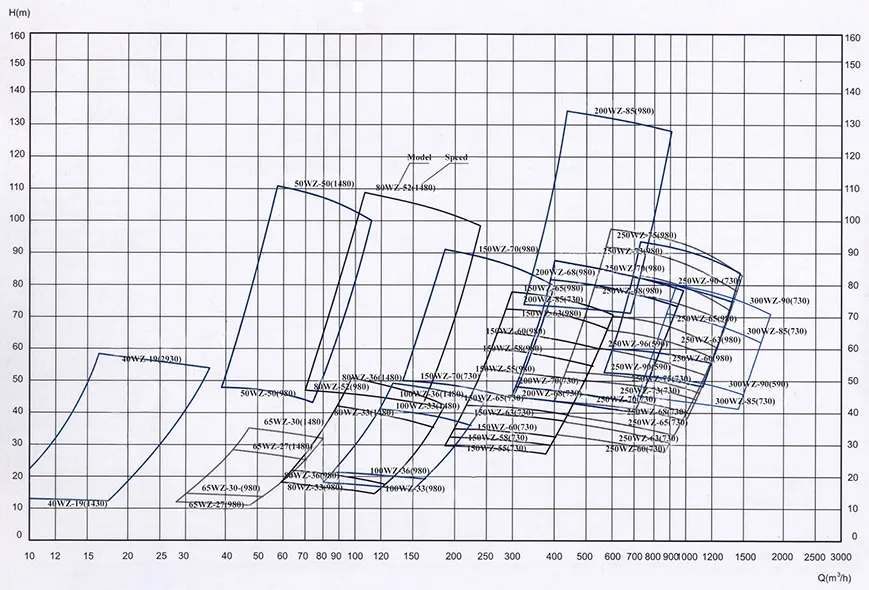

Q2: How do I select the correct specification for my well depth and required flow?

A: Calculate the Total Dynamic Head (TDH) and desired discharge (m³/h), select the corresponding pump curve from the submersible well pump manufacturer, and consider efficiency ratings for optimal energy use. Contact support for custom sizing.

-

Q3: What are typical pump shaft manufacturing standards?

A: Shafts from a reputable submersible pump shaft manufacturer are precision-forged from stainless steel or alloy treated with anti-fatigue processes, conforming to ISO 1940/1 balance standards.

-

Q4: Which spare parts are most critical for long-term pump operation?

A: Impellers, seals, bearings, and diffusers sourced from certified submersible pump spares manufacturer are essential for reducing downtime and extending overall lifespan.

-

Q5: What are standard installation guidelines for submersible pumps?

A: Follow manufacturer’s torque and alignment instructions, install a non-return valve above the pump, ensure full immersion, and commission with an electrical safety check via a certified electrician.

-

Q6: What electrical protections are recommended?

A: Earth-leakage (ELCB), overload, under-voltage, and over-current relays are vital for safe operation of any electrical submersible pump manufacturer model.

-

Q7: What is the difference between commercial and industrial submersible pumps?

A: Industrial variants generally handle higher flows, harsher fluids (high solids, chemical), and operate at stricter reliability and efficiency standards, while commercial pumps are lighter-duty for domestic or light water supply.

Contact: sales@aierpump.com | Tel: +86 156 3309 6988 | Online Inquiry

- Select your submersible well pump manufacturer based on expertise, documented quality standards, and capacity for customization.

- Focus on materials (alloy/rubber-lining) for your expected water, slurry, or sewage environment.

- Verify service, spares availability, and technical support—critical for operational reliability.

- Request comprehensive test reports, certificates, and performance curves directly from your supplier.

- Compare key technical benchmarks (efficiency, solids handling, motor enclosure rating) using transparent data and third-party recommendations.

Make Aier Machinery Hebei Co., Ltd your first choice to ensure world-class reliability in all well, sewage, industrial, or slurry pumping applications.

Reference: “Recent Advances in Submersible Pump Technology” – Water Journal (MDPI); Pump Industry Forum

This is the last article

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025

-

Premium Studs for Cover & Frame Plates | Corrosion-Resistant

NewsJul.20,2025

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025