Feb . 14, 2025 13:46 Back to list

high quality chemical centrifugal slurry pump

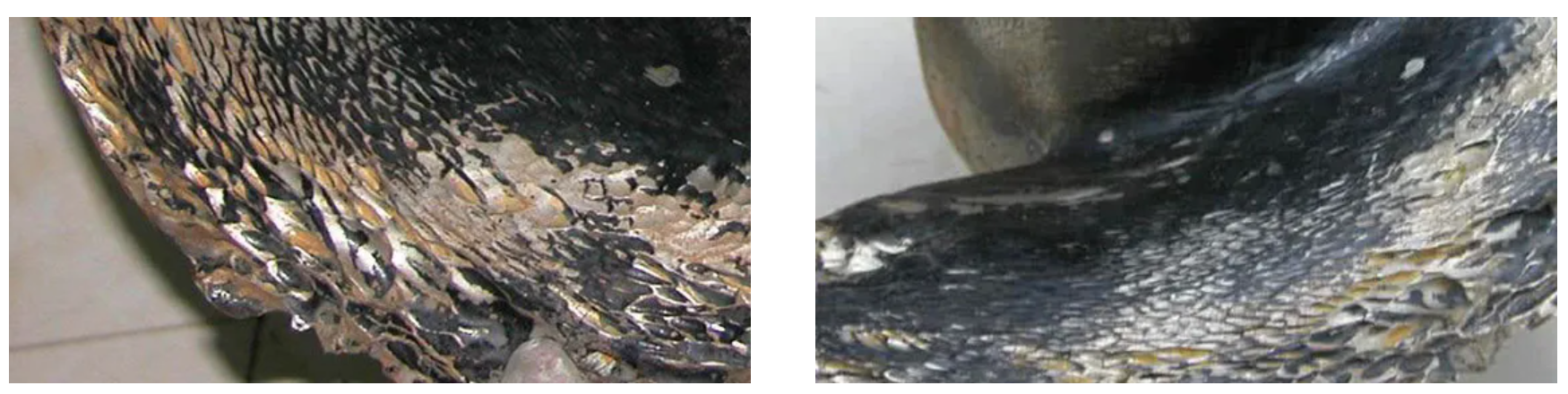

The realm of slurry pumps is integral to industries such as mining, metallurgical operations, coal washing, power plants, sewage water treatment, and more. Among the critical components of these pumps is the rubber impeller. A high-quality rubber impeller not only ensures efficient operation but also extends the lifespan of a slurry pump, thereby enhancing industrial productivity. This article delves into the intricacies of why investing in high-quality rubber impellers is paramount and how it elevates your operational experience.

Authoritativeness and Trustworthiness Engaging with manufacturers who have a proven track record and industry certifications ensures that you’re receiving high-authority products. Certifications like ISO 9001, coupled with the endorsements from third-party inspections, validate the manufacturer's commitment to quality and their authority in the field of slurry pump components. Trustworthiness also stems from transparent customer interactions, wherein manufacturers provide clear product documentation, service guarantees, and post-purchase support. Modern enterprises often extend full-fledged customization services, acknowledging that different installations might demand unique solutions. Optimizing Performance Through Experience Operational experience shows that high-quality rubber impellers significantly reduce downtime and maintenance costs. Energy consumption in slurry pumping can be substantial, but with an Impeller designed for efficiency, the reduction in resistance results in lower power usage and stable operations. This efficiency directly correlates to increased throughput and reduced wear on adjacent components. Industry professionals value high-grade rubber impellers as they offer superior return on investment. By minimizing the frequency of replacements and associated labor costs, these impellers ensure more continuous operational cycles, which are critical in time-sensitive industries. Conclusion High-quality rubber impellers are indispensable for any industry reliant on slurry pumps. They combine expertise in material science with precise engineering, thus ensuring superior performance under harsh conditions. As industries continue to push operational boundaries, relying on components like robust rubber impellers will remain essential for maintaining advantage and efficiency. Selecting the right component as a part of an overall strategy towards operational excellence can make a significant difference, providing measurable benefits in performance, longevity, and cost-effectiveness.

Authoritativeness and Trustworthiness Engaging with manufacturers who have a proven track record and industry certifications ensures that you’re receiving high-authority products. Certifications like ISO 9001, coupled with the endorsements from third-party inspections, validate the manufacturer's commitment to quality and their authority in the field of slurry pump components. Trustworthiness also stems from transparent customer interactions, wherein manufacturers provide clear product documentation, service guarantees, and post-purchase support. Modern enterprises often extend full-fledged customization services, acknowledging that different installations might demand unique solutions. Optimizing Performance Through Experience Operational experience shows that high-quality rubber impellers significantly reduce downtime and maintenance costs. Energy consumption in slurry pumping can be substantial, but with an Impeller designed for efficiency, the reduction in resistance results in lower power usage and stable operations. This efficiency directly correlates to increased throughput and reduced wear on adjacent components. Industry professionals value high-grade rubber impellers as they offer superior return on investment. By minimizing the frequency of replacements and associated labor costs, these impellers ensure more continuous operational cycles, which are critical in time-sensitive industries. Conclusion High-quality rubber impellers are indispensable for any industry reliant on slurry pumps. They combine expertise in material science with precise engineering, thus ensuring superior performance under harsh conditions. As industries continue to push operational boundaries, relying on components like robust rubber impellers will remain essential for maintaining advantage and efficiency. Selecting the right component as a part of an overall strategy towards operational excellence can make a significant difference, providing measurable benefits in performance, longevity, and cost-effectiveness.

Latest news

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025