Jun . 30, 2025 09:55 Werom nei list

Applications of Vertical Slurry Pump in Mining

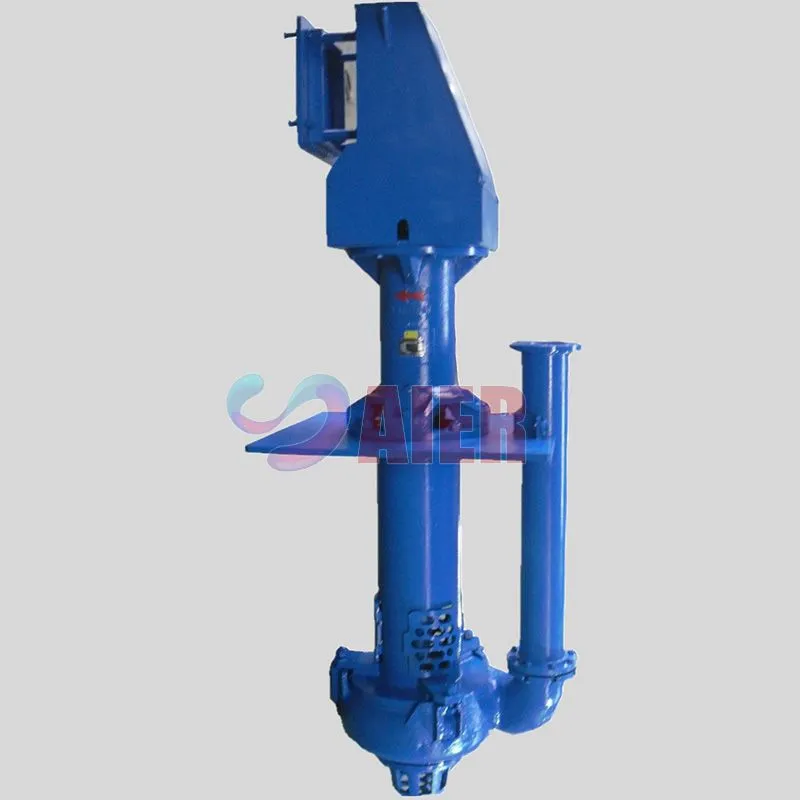

Mining operations involve a wide range of complex tasks, and the efficient handling of slurries is crucial for the success of these operations. Vertical slurry pump has emerged as an indispensable tool in the mining industry, offering reliable and effective solutions for various slurry - related challenges. Among them, submerged mining vertical slurry pump and china vertical slurry pump have become popular choices due to their superior performance and durability. This article will explore the diverse applications of vertical slurry pump in mining, highlighting how these pumps contribute to the smooth running of mining operations.

Dewatering in Mining with Submerged Mining Vertical Slurry Pump

One of the primary applications of vertical slurry pump in mining is dewatering. Mines often encounter significant water accumulation, which can pose risks to workers and equipment, and disrupt the mining process. Submerged mining vertical slurry pump is specifically designed to address this issue. These pumps can be directly submerged in water - filled areas such as mine shafts, sumps, or pits, allowing for efficient water removal.

The submersible design of these pumps eliminates the need for complex suction systems, enabling them to operate in deep and hard - to - reach places. China vertical slurry pump manufacturers produce these pumps with high - power motors and robust construction, ensuring they can handle large volumes of water even in harsh mining environments. By effectively dewatering mines, submerged mining vertical slurry pump helps create a safer working environment and ensures continuous mining operations without interruptions caused by waterlogging.

Transporting Ore - Bearing Slurries with Vertical Slurry Pump

In the mining process, after the ore is extracted, it is often mixed with water to form a slurry for easier transportation. Vertical slurry pump plays a vital role in transporting these ore - bearing slurries from the extraction site to processing facilities. These pumps are capable of handling slurries with high solid contents, ensuring that the ore is transported efficiently over long distances.

The design of vertical slurry pump allows for high - pressure and high - flow - rate operations, which are essential for moving heavy slurries through pipelines. China vertical slurry pump models are known for their reliable performance in this application. They are equipped with wear - resistant components such as impellers and casings, which can withstand the abrasive nature of ore particles in the slurry. This ensures the longevity of the pump and reduces maintenance costs, making them a cost - effective solution for ore transportation in mining operations.

Tailings Disposal Using China Vertical Slurry Pump

Tailings disposal is another critical aspect of mining, and China vertical slurry pump is widely used in this process. Tailings, the waste materials left after ore processing, need to be safely transported and stored. China vertical slurry pump is designed to handle the unique characteristics of tailings slurries, which may contain fine particles and chemicals.

These pumps can pump tailings slurries to designated storage areas, such as tailings dams or ponds. The robust construction and high - performance capabilities of China vertical slurry pump ensure that the tailings are transported smoothly and without leakage. Additionally, the advanced manufacturing technologies employed by Chinese manufacturers result in pumps that are energy - efficient, helping mining companies reduce their operational costs while ensuring environmentally friendly tailings disposal.

Slurry Recycling with Submerged Mining Vertical Slurry Pump

Mining operations are increasingly focused on sustainable practices, and slurry recycling is an important part of this effort. Submerged mining vertical slurry pump is used to recycle water and valuable materials from slurries. By pumping the slurry back to the processing system, these pumps help recover water for reuse in the mining process, reducing water consumption and costs.

Moreover, in some cases, valuable minerals or metals may still be present in the slurry. Submerged mining vertical slurry pump enables the transportation of the slurry to recovery facilities, where these valuable components can be extracted. The ability of these pumps to operate continuously and efficiently in submerged conditions makes them ideal for slurry recycling applications, contributing to the overall sustainability and economic viability of mining operations.

Vertical Slurry Pump in Mining FAQS

Why are submerged mining vertical slurry pump preferred for dewatering?

Submerged mining vertical slurry pump is preferred for dewatering because of its submersible design. It can be directly placed in water - filled areas in mines, eliminating the need for complex suction setups. This allows it to operate in deep and hard - to - reach locations, efficiently removing large volumes of water. Its robust construction, often found in china vertical slurry pump models, ensures it can withstand the harsh mining environment, making it a reliable choice for dewatering tasks.

Can vertical slurry pump handle high - density ore - bearing slurries?

Yes, vertical slurry pump is designed to handle high - density ore - bearing slurries. These pumps are built with powerful motors and components that can generate high pressure and flow rates, enabling them to move heavy slurries over long distances. The wear - resistant materials used in their construction, especially in china vertical slurry pump, can withstand the abrasion caused by ore particles, ensuring continuous and efficient operation even with high - density slurries.

What makes china vertical slurry pump suitable for tailings disposal?

China vertical slurry pump is suitable for tailings disposal due to its robust construction and advanced manufacturing. These pumps can handle the unique properties of tailings slurries, including fine particles and potentially corrosive substances. They are capable of pumping tailings to designated storage areas with high efficiency and reliability. Additionally, many china vertical slurry pump models are designed to be energy - efficient, which helps mining companies reduce costs during the tailings disposal process.

How does submerged mining vertical slurry pump contribute to slurry recycling?

Submerged mining vertical slurry pump contributes to slurry recycling by pumping the slurry back to the processing system. This allows for the recovery of water, which can be reused in the mining process, reducing water consumption. It also enables the transportation of slurry containing potentially valuable materials to recovery facilities, where these materials can be extracted. Its ability to operate continuously in submerged conditions ensures a smooth and efficient slurry recycling process.

Are china vertical slurry pump easy to maintain in mining operations?

Many china vertical slurry pump models are designed with maintenance in mind. They often feature modular components, which makes it easier to replace worn - out parts. The use of durable and wear - resistant materials reduces the frequency of maintenance. Additionally, Chinese manufacturers usually provide comprehensive maintenance guidelines and after - sales support, helping mining companies keep their china vertical slurry pump in good working condition with relatively low maintenance efforts.

-

New Developments in Rubber Slurry Pump Factory

NijsJun.30,2025

-

Industrial Applications of Submersible Water Pumps

NijsJun.30,2025

-

How Quality Ceramic Slurry Pump Enhances Efficiency

NijsJun.30,2025

-

Heat Treatment of Metal Slurry Pump Parts

NijsJun.30,2025

-

FGD Pump Installation Best Practices

NijsJun.30,2025

-

Applications of Vertical Slurry Pump in Mining

NijsJun.30,2025