جولای . 08, 2025 07:37 Back to list

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

- Overview of Submersible Pump Companies: Market Dynamics and Industry Growth

- Technological Innovations and Competitive Advantages in Submersible Pumps

- Comparative Analysis of Top Manufacturers: Quality, Output, and Reliability

- Custom Solutions and Engineering Flexibility

- Case Studies and Real-world Applications

- Key Considerations When Selecting Your Supplier

- How Leading submersible pump companies

Shape the Future of Fluid Handling

(submersible pump companies)

Overview of submersible pump companies: Global Market and Industrial Momentum

The global demand for submersible pumps has experienced robust growth, driven by increased infrastructure development, urbanization, and stricter environmental regulations. According to recent market research, the submersible pump sector is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2022 to 2027, reaching approximately $17.8 billion by the end of the forecast period. North America, Asia-Pacific (especially China), and Europe represent the largest markets. China submersible pump companies suppliers have particularly contributed to market dynamism, ranking amongst the globe’s top exporters due to their cost-effective manufacturing, rapid scaling ability, and broad portfolio coverage. Factors driving industry momentum include:

- Urban water & wastewater treatment investments

- Energy-efficient infrastructure upgrades

- Growing requirements for agricultural irrigation solutions

- Implementation of advanced monitoring and automation

Technological Innovations and Competitive Advantages

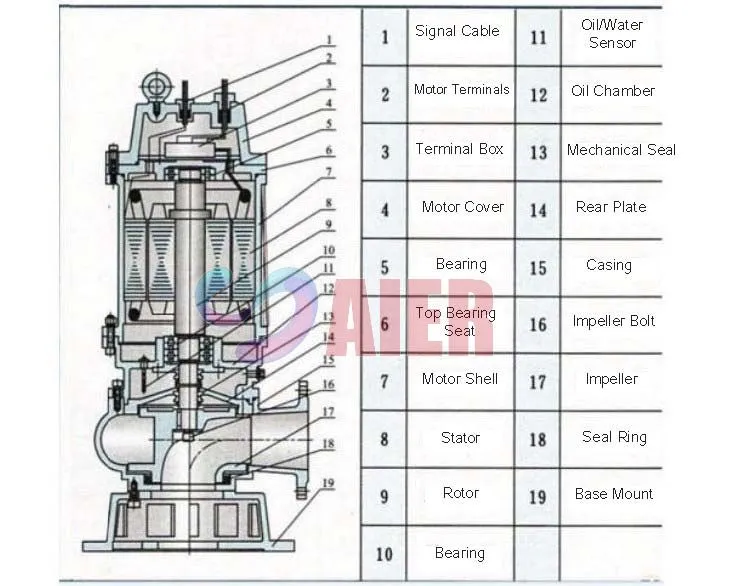

Submersible pump manufacturers have intensified research and development to stay ahead in productivity, cost reduction, and efficiency. Recent breakthroughs include the adoption of permanent magnet motors boasting efficiency ratings above 90%, vortex impeller technologies to reduce clogging, and digital monitoring systems designed to minimize downtime. Many leading suppliers now offer products compliant with international standards such as ISO 5199, IECEx/ATEX for hazardous environments, and NSF/ANSI 61 for potable water applications.

Technical advantages setting premium manufacturers apart:

- Energy efficiency: State-of-the-art drives, impeller geometries, and cooling systems enabling up to 30% energy savings.

- Material Science: Use of duplex and super duplex stainless steels increases resistance to corrosion and wear in aggressive environments by 45% compared to traditional materials.

- Remote Sensing & IoT: Integration of predictive maintenance platforms decreases unscheduled outages by up to 50%.

Comparative Analysis of Top Submersible Pump Manufacturers

Selecting the right partner among high quality submersible pump companies manufacturers involves evaluating technical excellence, production capacity, customization ability, and after-sales support. The table below compares leading global suppliers, including prominent China-based companies, by core performance metrics:

| Company | Annual Output (Units) |

Certifications | Energy Efficiency (% Peak) |

Custom Engineering | Avg. Delivery (weeks) |

Key Industry Focus |

|---|---|---|---|---|---|---|

| Franklin Electric (USA) | 2,000,000 | ISO 9001, CE, UL | 89 | Extensive | 6-8 | Municipal, Irrigation, Mining |

| Ebara (Japan) | 1,600,000 | ISO 14001, NSF/ANSI 61 | 92 | Comprehensive | 7-9 | Commercial, Water Treatment |

| Walrus Pump (Taiwan) | 800,000 | CE, ISO 9001 | 88 | Moderate | 8-10 | Agricultural, Domestic |

| Leo Group (China) | 2,500,000 | ISO 9001, CCC | 91 | Strong | 6-8 | Irrigation, Industrial |

| Grundfos (Denmark) | 3,400,000 | ISO 5199, ATEX, WRAS | 94 | Full Custom Design | 5-7 | Municipal, Energy, Water Supply |

| Wenling City Pump Factory (China) | 750,000 | ISO 9001, ISO 14001 | 87 | Limited | 7-10 | Agriculture, Municipal |

As illustrated, advanced efficiency, broad customization, and rigorous certifications are distinguishing factors among world-class submersible pump producers. China submersible pump companies suppliers are increasingly closing the gap with global incumbents through rapid adoption of technical standards and automation.

Custom Solutions and Engineering Flexibility

Customization is now a decisive factor as end-users seek pumps tailored to specific site conditions, flow rates, chemical exposure, and integration requirements. Leading manufacturers provide engineering services such as:

- 3D modeling and CFD simulation for bespoke hydraulic design

- Alternative wetted-path material selections (e.g., titanium, PTFE-coatings)

- Motor options including explosion-proof, sub-arctic, and solar-compatible units

- Shaft seal configurations for slurry and high-solids applications

- Proprietary anti-vibration and self-cleaning assemblies

Case Studies and Application Highlights

Demonstrating technical prowess and project success, the following selected cases showcase the practical application of high-quality submersible pump systems:

- Shanghai Sewage Treatment Expansion (China): In cooperation with leading China suppliers, a 12-station municipal wastewater upgrade deployed 48 high-capacity submersible pumps (rated 600 L/s per unit), achieving a 23% reduction in energy costs and a 37% improvement in processed water volumes after commissioning.

- Offshore Oil Platform (North Sea): A global manufacturer provided saltwater-resistant, ATEX-certified submersible pumps to address unpredictable wave loads and high chloride, allowing continuous operations with less than 2% annual unscheduled downtime—well below the industry average of 7%.

- Agricultural Irrigation Project (Australia): Multistage submersible units with solar-compatible drives allowed year-round irrigation with a pump lifecycle extension of 28% in remote, energy-scarce regions.

- Deep Mining Dewatering (South Africa): Local and international manufacturers supplied fully enclosed, abrasion-resistant submersible pumps for gold mines, successfully removing abrasive slurries at depths over 1,400 meters, resulting in a reliable yield increase.

Key Considerations When Selecting Your Supplier

Beyond technical specifications, several strategic considerations dictate the choice of submersible pump partner:

- Global Support Infrastructure: Availability of rapid-response service teams and authorized spares distribution.

- Lifecycle Costs: Assessing not just upfront investment, but also expected energy, maintenance, and replacement costs across a 10-15 year period.

- Regulatory Compliance: Ensuring pumps are certified for the intended application—potable, sanitary, explosive, or corrosive liquids.

- Digital Integration: Ability to synchronize with existing control platforms and harness real-time data analytics for predictive maintenance.

- Environmental Impact: Manufacturers offering recyclable materials, reduced noise, and minimized fluid loss enhance environmental sustainability.

How Leading submersible pump companies Shape the Future of Fluid Handling

The ongoing evolution within the submersible pump market is characterized by a focus on energy efficiency, adaptability, and digital transformation. Top manufacturers are setting new industry benchmarks by integrating smart monitoring, automation, and advanced material science into their product lines. As a result, facilities managers and engineers can achieve:

- 20-40% reductions in total operating costs through optimized systems

- Expanded asset lifespan owing to wear-resistant components and proactive maintenance technology

- Improved sustainability metrics consistent with global environmental targets

(submersible pump companies)

FAQS on submersible pump companies

Q: What are submersible pump companies?

A: Submersible pump companies design and manufacture pumps that operate underwater. These pumps are used in applications like drainage, sewage, and water wells. Such companies often provide both residential and industrial solutions.Q: How do I find reliable China submersible pump companies suppliers?

A: You can research online directories and industry platforms to compare suppliers. Look for verified credentials, customer reviews, and export experience. It's also beneficial to request product samples for quality assessment.Q: What makes a manufacturer a high quality submersible pump company?

A: High quality manufacturers use premium materials and advanced technology in their pumps. They maintain strict quality control and offer comprehensive after-sales support. Certifications like ISO 9001 are also a positive indicator.Q: Are there advantages to working with high quality submersible pump companies manufacturers?

A: Yes, these manufacturers generally offer durable products with superior performance. They provide reliable warranties and timely technical assistance. This ensures long-term satisfaction and reduced operational downtime.Q: How can I verify if a submersible pump company in China is reputable?

A: Check for company certifications, years of experience, and positive client testimonials. Verify business licenses and inspect production facilities if possible. Collaborating with well-known brands adds an extra layer of trust.This is the last article

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025