Ots . 13, 2025 04:40 Back to list

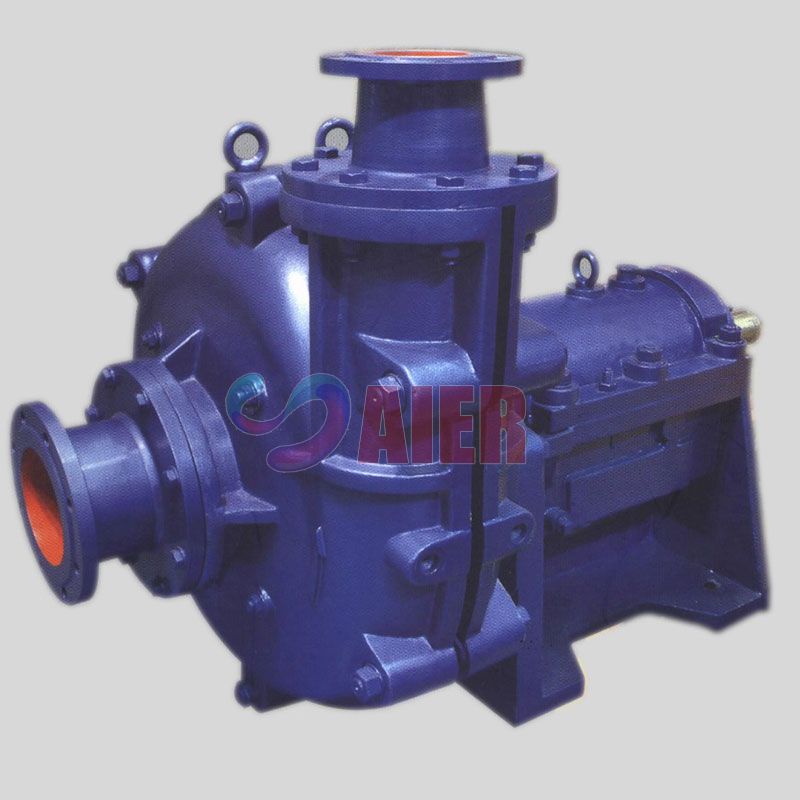

WZ High Efficiency Slurry Pump

Selecting the right slurry pump impeller material is crucial for ensuring the efficiency, reliability, and longevity of your pumping system. Slurry pumps are fundamental to industries such as mining, wastewater treatment, and construction, tasked with transporting abrasive and corrosive mixtures. Given the demanding nature of these applications, the material composition of the impeller—the pump’s core component—determines not just performance but also cost-effectiveness and maintenance frequency.

When fine-tuning slurry pump system performance, material compatibility with the conveyed substance remains paramount. Each slurry composition has distinct characteristics that could react adversely with the impeller, underscoring the need for careful material selection. Consulting with manufacturers and material scientists can provide additional insights tailored to specific operational requirements. Additionally, advancements in material science have introduced enhanced ceramic and polymer coatings, extending the lifespan of metal impellers by imparting additional wear resistance. These ancillary materials provide a barrier against the harshest elements encountered in slurry processing, further reducing maintenance downtime and costs. Ultimately, the choice of impeller material should be approached with a comprehensive understanding of the operational environment and mechanical demands. Collaboration with industry specialists ensures that the selected material aligns with both performance goals and budgetary constraints, providing a competitive edge through optimized reliability and cost management. Beyond material selection, regular inspection and maintenance regimes are instrumental in prolonging impeller lifespan, regardless of the chosen material. Establishing a predictive maintenance system, leveraging technologies like condition monitoring, will preemptively address wear issues before catastrophic failures occur, securing operational continuity and safeguarding capital investment. In conclusion, the science behind slurry pump impeller materials is intricate, rooted in balancing application-specific challenges with material strengths. Each material offers unique benefits tailored to particular operational conditions, underlining the necessity for informed decision-making. As industries evolve, new materials and innovations will continue to emerge, revolutionizing slurry handling through progressively sophisticated and resilient solutions.

When fine-tuning slurry pump system performance, material compatibility with the conveyed substance remains paramount. Each slurry composition has distinct characteristics that could react adversely with the impeller, underscoring the need for careful material selection. Consulting with manufacturers and material scientists can provide additional insights tailored to specific operational requirements. Additionally, advancements in material science have introduced enhanced ceramic and polymer coatings, extending the lifespan of metal impellers by imparting additional wear resistance. These ancillary materials provide a barrier against the harshest elements encountered in slurry processing, further reducing maintenance downtime and costs. Ultimately, the choice of impeller material should be approached with a comprehensive understanding of the operational environment and mechanical demands. Collaboration with industry specialists ensures that the selected material aligns with both performance goals and budgetary constraints, providing a competitive edge through optimized reliability and cost management. Beyond material selection, regular inspection and maintenance regimes are instrumental in prolonging impeller lifespan, regardless of the chosen material. Establishing a predictive maintenance system, leveraging technologies like condition monitoring, will preemptively address wear issues before catastrophic failures occur, securing operational continuity and safeguarding capital investment. In conclusion, the science behind slurry pump impeller materials is intricate, rooted in balancing application-specific challenges with material strengths. Each material offers unique benefits tailored to particular operational conditions, underlining the necessity for informed decision-making. As industries evolve, new materials and innovations will continue to emerge, revolutionizing slurry handling through progressively sophisticated and resilient solutions.

Next:

Latest news

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025