Uzt . 23, 2025 03:01 Back to list

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

Global Partner to Power, Metallurgy, Coal & Fluid Management Industries

About Aier Machinery Hebei Co., Ltd

Aier Machinery Hebei Co., Ltd is a leading submersible well pump manufacturer and innovator in the pump industry, providing high-performance solutions for diverse industrial applications worldwide. Established in Hebei, China, our company specializes in the R&D, production, and distribution of advanced pumps, precision spares, and vital components.

Official Website: https://www.aierpumps.com

Tel: +86 156 3309 6988 | Mobile: +86 311 6796 2586

E-mail: sales@aierpump.com

1. Industry Trends: Submersible Well Pump Manufacturer Market Overview

As a recognized submersible well pump manufacturer, Aier Machinery Hebei Co., Ltd closely tracks global industry trends. The global market for submersible pumps — encompassing submersible water pump manufacturer, submersible sewage pump manufacturer, and related sectors — is undergoing rapid growth, fueled by global water resource management initiatives, infrastructure modernization, and environmental regulations (Grand View Research, 2023).

Key demand drivers include: rising agricultural irrigation needs, mining and construction activities, power generation, and the relentless push for energy-efficient pumping solutions. As a china submersible pump manufacturer with global reach, Aier combines engineering expertise with international quality standards.

2. Technological Evolution & Parameters

Core advancements among submersible well pump manufacturers relate to improved motor efficiency, material innovations (e.g., stainless steel, duplex chromium alloys for corrosion/abrasion resistance), sophisticated sealing technology, and modular, serviceable designs. Automation, IoT/remote monitoring, and customized hydraulic profiles further expand reliability and user control [Pumps & Systems Journal].

Essential Parameters in Submersible Well Pump Selection

| Parameter | Typical Values | Industry Standard | Comments |

|---|---|---|---|

| Flow Rate (Q) | 5 - 1500 m³/h | ISO 9906, API 610 | Project-dependent |

| Head (H) | 20 - 1200 m | DIN EN 12723 | High-head for deep-well & mining |

| Power (kW) | 1.1 - 500 kW | IEC, NEMA | Electrical submersible pump manufacturer standard |

| Efficiency | 55% - 85% | EuP/ErP | Efficiency drives cost & CO2 impact |

| Max Solid Size | 8 - 76 mm | ISO 9906 | Critical for sewage/slurry duty |

| Materials | Cast iron, SS304/6, Duplex, Bronze | ASTM/ISO | Corrosion, abrasion resistance |

| Protection Rating | IP68 | IEC 60529, NEMA 6 | Submersion safety |

3. Technical Parameter Trend Visualization

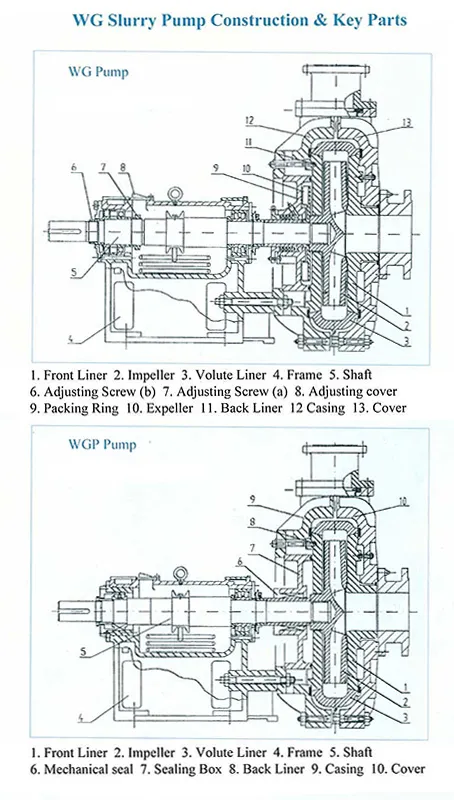

4. WG High Head Slurry Pump – Flagship Product Spotlight

Dedicated to market-leading innovation as a manufacturer of submersible pump, Aier presents the WG High Head Slurry Pump — our performance benchmark for power, metallurgy, coal, and process plant applications.

- Product Concept: Specifically engineered for large capacity, high head, and multi-stage operation in harshest environments, including ash removal, sludge transport, tailings, and high-density fluid mixtures.

- Design Heritage: Developed from decades of hydraulic design and manufacturing expertise for demanding mining and plant conditions.

- Flexibility: Modular construction, allowing configuration for varied solid concentrations and pumped chemicals.

- Compliance: Built per ISO, API, and regional standards.

- Product Page: WG High Head Slurry Pump

Main Technical Specifications: WG High Head Slurry Pump

| Model | Capacity (m³/h) | Head (m) | Allowed Solid Size (mm) | Efficiency (%) | Power (kW) | Material |

|---|---|---|---|---|---|---|

| WG-100 | 80 - 340 | 30 - 75 | 35 | 65 | 75 | HiCr Alloy/SS316 |

| WG-250 | 180 - 950 | 50 - 148 | 40 | 70 | 160 | HiCr Alloy |

| WG-400 | 600 - 2100 | 80 - 220 | 56 | 72 | 250 | Duplex SS |

| WG-600 | 1200 - 3800 | 120 - 350 | 70 | 75 | 355 | HiCr/SS316 |

5. Pie Chart: Material Distribution in WG High Head Slurry Pump

- HiCr Alloy (45%)

- SS316 (25%)

- Duplex Steel (20%)

- Other Alloys (10%)

6. Application Scenarios & Use Cases

- Deep-well water extraction for municipal, commercial, and agricultural supply [submersible well pump manufacturer]

- Transfer duties in raw water and industrial water supply (submersible water pump manufacturer)

- Sewage and wastewater effluent management for treatment plants (submersible sewage pump manufacturer)

- Sludge, slurry, and ash disposal from power plants, mining, and metallurgy process (WG High Head Slurry Pump flagship series)

- Extreme environments: corrosive, abrasive, solid-laden, or high temperature duties

- Remote control & monitoring for automated, unmanned or hazardous area pumping (electrical submersible pump manufacturer advances)

- Customized solutions for process plant retrofit and energy efficiency upgrades

7. FAQ: Professional FAQ for Submersible Well Pump Engineering

Reference: ScienceDirect – Advanced Pump Materials Study

8. Key Competitive Advantages of Aier Machinery Hebei Co., Ltd

- Comprehensive OEM Capabilities: Custom pumps, spares and assemblies (submersible pump part manufacturer expertise)

- Full Supply Chain Integration: In-house casting, machining, testing, and QC for total reliability.

- Export Credentials: Serving over 40 countries — compliance with ISO, CE, API, IEC and major local certifications.

- Research & Development: Advanced CFD modeling, material science, and smart technology R&D partnerships with top engineering institutes.

- Rapid Technical Support: Multilingual, 24/7 technical engineering and aftersales service.

- Long-Term Performance Data: Reference installations across power, mining, metallurgy, and infrastructure projects, validated by customer testimonials and published case studies.

9. Smart Manufacturing & Sustainability in Pump Production

As a forward-thinking centrifugal submersible pump manufacturer, Aier Machinery Hebei Co., Ltd invests in green manufacturing: optimizing foundry and machine shop emissions, recycling water, and broadening the use of eco-friendly coatings and lubricants. Automation and real-time IoT monitoring reduce energy use, unplanned downtime, and ensure compliance with modern sustainability standards (Water Environment Federation Industry Blog).

10. Future Outlook and Global Partnerships

Aier Machinery Hebei Co., Ltd aims to be recognized not only as a top submersible well pump manufacturer but also as the partner of choice for water, slurry, and process fluid management worldwide. We continue to build relationships with international engineering firms, EPC contractors, and process plant owners to design pump sets that deliver unmatched reliability and cost efficiency.

For inquiries on submersible well pump manufacturer solutions, collaboration, or distributorship, visit https://www.aierpumps.com or contact our technical team via phone, email, or our online contact form.

11. References & Industry Authority

2. Pumps & Systems Journal, “Integrating IoT with Submersible Pumps”, https://www.pumpsandsystems.com/integrating-iot-submersible-pumps

3. ScienceDirect, “Advances in Pump Material Systems”, https://www.sciencedirect.com/science/article/abs/pii/S092150932031203X

4. Water Environment Federation, “Pumps, Sensors, & Sustainability”, https://www.wef.org/news-hub/wef-blog/wefb-2021/pumps-sensors-sustainability/

This is the last article

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025

-

Premium Studs for Cover & Frame Plates | Corrosion-Resistant

NewsJul.20,2025

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025