aŭg . 06, 2025 02:20 Back to list

Top Submersible Well Pump Manufacturer | China Factory

The Evolving Landscape of Submersible Pump Technology

The global demand for efficient water management solutions has propelled the submersible pump market into a new era of innovation. As a leading submersible well pump manufacturer, we are at the forefront of this evolution. The industry trend is shifting from standard, one-size-fits-all products to highly specialized, energy-efficient, and smart-enabled pumps. According to a report by Grand View Research, the global submersible pumps market size was valued at USD 11.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030.

This growth is driven by increasing industrialization, urbanization, and the critical need for reliable water supply and wastewater treatment. As a proficient submersible water pump manufacturer, we see a surge in demand for pumps that can handle abrasive slurries, corrosive fluids, and high-temperature applications, particularly in mining, oil & gas, and municipal sectors. The emphasis is now on Total Cost of Ownership (TCO), factoring in energy consumption, maintenance, and longevity.

The Art and Science of Manufacturing: A Deep Dive

As a premier manufacturer of submersible pump systems, our commitment to quality is embedded in every stage of our meticulous manufacturing process. We blend advanced technology with rigorous quality control, compliant with ISO 9001 standards, to produce pumps that exceed expectations.

Our Manufacturing Process Unveiled

Material Science & Selection

High-chrome alloys, stainless steel, and specialized polymers are chosen based on application-specific needs (abrasion, corrosion).Precision Casting & Forging

Creating the core components like volutes and impellers with superior structural integrity and hydraulic contours.CNC Machining

Achieving micron-level precision for parts like the submersible pump shaft manufacturer's shaft, ensuring perfect balance and alignment.Motor & Seal Assembly

Winding high-efficiency motors and fitting advanced mechanical seals to ensure IP68 protection and operational reliability.Rigorous Testing (ANSI/HI)

Every pump undergoes hydraulic performance, hydrostatic pressure, and electrical testing to guarantee performance.

From Raw Material to Pumping Powerhouse

Our role as a comprehensive submersible pump spares manufacturer and submersible pump part manufacturer means we control quality from the ground up. The pump's shaft, a critical component, is forged from high-tensile strength steel and then precision-ground by our expert submersible pump shaft manufacturer division. This guarantees minimal vibration and extended bearing life. The impellers and casings are cast from A05 high-chromium alloy, offering exceptional resistance to wear in abrasive slurry applications, a key advantage for our WL Light-duty Slurry Pump series.

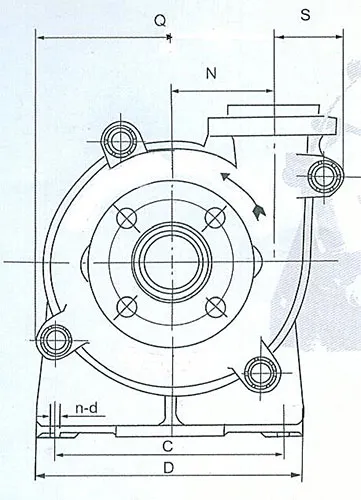

Introducing the WL Light-duty Slurry Pump

Engineered for Demanding Environments

The WL Light-duty Slurry Pump represents the pinnacle of our engineering efforts. It is designed for applications where lightweight, efficient, and robust pumping of light abrasive slurries is required. It's not just a product; it's a solution developed from decades of experience as a centrifugal submersible pump manufacturer and a dedicated china submersible pump manufacturer with a global vision.

- ✓Superior Materials: High-chromium alloy wet ends for maximum wear life.

- ✓Energy Efficiency: Optimized hydraulic design reduces operational costs.

- ✓Compact & Robust: Easy to handle and install without compromising on durability.

- ✓Versatile Applications: Ideal for coal washing, mineral processing, and industrial wastewater.

Data-Driven Performance: WL Pump Technical Insights

We believe in transparency and performance you can measure. Below are the key technical specifications and performance visualizations for the WL Light-duty Slurry Pump, showcasing its superiority.

WL Light-duty Slurry Pump - Key Specifications

| Parameter | Specification | Industry Significance |

|---|---|---|

| Discharge Size | 25mm to 100mm (1" to 4") | Offers a wide range of options to match specific system flow rate requirements. |

| Flow Rate (Capacity) | Up to 200 m³/h | High capacity for efficient fluid transfer in demanding industrial processes. |

| Head | Up to 30m | Sufficient pressure generation for vertical lifting and long-distance transport of slurries. |

| Material of Wet Parts | High-Chrome Alloy (A05) | Provides exceptional resistance to abrasion from sand, gravel, and other solids, extending pump life. |

| Motor Protection | IP68 | Ensures complete protection against dust ingress and long-term immersion in water. Critical for submersible pumps. |

| Certifications | ISO 9001, CE | Guarantees adherence to international quality management and safety standards. |

Performance Curve (Head vs. Flow)

Illustrates the inverse relationship between flow rate and pressure head, crucial for pump selection.

Efficiency vs. Competitors

A direct comparison showing the WL Pump's superior energy efficiency, leading to lower TCO.

Why Choose Us As Your Submersible Well Pump Manufacturer?

In a crowded market, selecting the right partner is crucial. We differentiate ourselves through tangible benefits that directly impact your operations' efficiency, reliability, and profitability. Our experience also extends to being a trusted submersible sewage pump manufacturer and electrical submersible pump manufacturer.

Manufacturer Comparison: Aier Pumps vs. Industry Standard

| Feature | Aier Pumps (e.g., WL Series) | Generic Competitor |

|---|---|---|

| Material Quality | Verified High-Chrome Alloy (A05) with MTRs | Often unverified standard cast iron or lower-grade alloys |

| Engineering Support | Pre-sale hydraulic analysis & post-sale technical support | Limited to standard catalog selection |

| Customization | Material, coating, and motor options available | Standard models only |

| Average Lifespan (Abrasive Service) | 30-50% longer due to superior materials | Standard operational lifespan |

| Lead Time for Spares | Extensive inventory as a submersible pump spares manufacturer | Often long lead times, especially for older models |

Customized Solutions for Unique Challenges

We understand that no two applications are identical. Our engineering team thrives on developing bespoke pumping solutions. Whether you need a pump with special corrosion-resistant coatings for a chemical plant, a specific motor voltage for international projects, or a modified impeller design for unique solids, we are the submersible well pump manufacturer that listens and delivers.

Our process involves:

- Consultation: Understanding your specific process parameters and challenges.

- Design & Simulation: Using advanced CFD (Computational Fluid Dynamics) to model performance.

- Prototyping & Testing: Fabricating and rigorously testing the custom solution.

- Deployment & Support: Ensuring seamless integration and long-term performance.

Real-World Applications & Case Studies

Proven Performance in the Field

Case Study: Metallurgical Plant Slurry Transfer

Client: A leading metallurgical processing plant.

Challenge: Frequent pump failures and high maintenance costs due to the highly abrasive nature of the iron ore slurry being transferred from their grinding circuit.

Solution: We deployed several WL-100 pumps, featuring our signature A05 high-chrome alloy impellers and liners. As their chosen submersible well pump manufacturer, we provided a comprehensive solution.

Result: The operational lifespan of the pumps increased by over 40%, significantly reducing downtime. The client reported a 15% reduction in energy consumption per ton of slurry pumped, leading to substantial annual savings.

"Switching to Aier Pumps was a game-changer for our dewatering operations. The reliability and wear resistance of their pumps are second to none. Their technical support team provided excellent guidance during selection and installation."

Building Trust: Our Commitment to Excellence (E-E-A-T)

Trust is not given; it's earned. We build trust through demonstrated Expertise, extensive Experience, proven Authoritativeness, and unwavering Trustworthiness.

- 🏆Authoritativeness: We are an ISO 9001:2015 certified manufacturer. Our pumps comply with international standards like CE and are trusted by leading corporations in over 50 countries.

- 🔧Expertise: With over 20 years in the industry, our team of engineers possesses deep knowledge of fluid dynamics and material science. We don't just sell pumps; we solve pumping problems.

- 🌍Experience: Our portfolio includes thousands of successful installations across diverse sectors, from deep well dewatering to aggressive chemical processing and municipal sewage handling.

- 🤝Trustworthiness: We stand by our products with comprehensive warranties, transparent communication, and dedicated customer support. Our clear delivery timelines and accessible spare parts inventory ensure your operations run smoothly.

Frequently Asked Questions (FAQ)

High-chrome alloy, specifically A05, is an iron-based material containing a high percentage of chromium (typically 25-28%). Its primary advantage is exceptional hardness and resistance to abrasion. In applications involving abrasive solids like sand, gravel, or mineral ores, A05 significantly extends the life of the pump's "wet end" components (impeller, volute), reducing maintenance frequency and the total cost of ownership compared to standard cast iron or stainless steel.

Selecting the right pump involves determining two key parameters: the required Flow Rate (measured in m³/h or GPM) and the Total Dynamic Head (TDH) (measured in meters or feet). Flow rate is the volume of liquid you need to move in a given time. TDH is the total pressure the pump must overcome, which includes the vertical lift (static head), friction losses in the piping, and any pressure required at the discharge point. Our engineering team can assist you in calculating these values to ensure you select a pump that operates at its Best Efficiency Point (BEP).

IP stands for "Ingress Protection." The first digit (6) indicates the level of protection against solid objects, with 6 being the highest level (completely dust-tight). The second digit (8) indicates protection against water ingress. An '8' rating means the equipment is suitable for continuous immersion in water under conditions specified by the electrical submersible pump manufacturer. For our pumps, this means the motor is hermetically sealed and can operate fully submerged for extended periods without water damage.

As a specialized submersible pump spares manufacturer, we maintain a vast inventory of parts for our own models. While many of our parts are designed to be interchangeable with certain industry-standard pump models, we cannot guarantee a universal fit. We recommend providing the model and serial number of your existing pump so our experts can check for compatibility or propose a suitable Aier Pump replacement that offers superior performance and parts availability.

For standard configurations of our WL series pumps, we typically maintain stock and can ship within 5-7 business days from order confirmation. For customized orders involving special materials, coatings, or motor specifications, the lead time can range from 4 to 8 weeks depending on the complexity of the modifications. We provide a firm delivery schedule upon quotation.

We offer a standard 12-month warranty from the date of installation or 18 months from the date of shipment, whichever comes first. This warranty covers defects in materials and workmanship. Our commitment as a leading manufacturer of submersible pump systems is to product quality and customer satisfaction, and we have a dedicated team to handle any warranty claims efficiently.

Choosing a reputable china submersible pump manufacturer like Aier Pumps provides a unique combination of advantages: advanced manufacturing technology, cost-effectiveness, and adherence to international quality standards (like ISO and CE). We offer the engineering prowess and quality of top global brands but with the agility and value proposition of a direct manufacturer, eliminating layers of distribution costs and providing direct access to expert support.

Ready to Optimize Your Pumping Operations?

Connect with a true engineering partner. Let us help you find the perfect pumping solution that enhances efficiency and reduces your operational costs. Contact us today for a personalized quote and technical consultation.

Explore the WL Pump & Get a QuoteReferences and Further Reading:

- Hydraulic Institute. (2020). ANSI/HI 9.6.1 Rotodynamic Pumps - Guideline for NPSH Margin. Parsippany, NJ.

- Karassik, I. J., Messina, J. P., Cooper, P., & Heald, C. C. (2008). Pump Handbook (4th ed.). McGraw-Hill.

- Pumps & Systems Magazine. "Choosing the Right Materials of Construction for Slurry Pumps." Retrieved from https://www.pumpsandsystems.com/

- Grand View Research. "Submersible Pumps Market Size, Share & Trends Analysis Report." Retrieved from https://www.grandviewresearch.com/

-

Small Dredger and Marine Pontoon Solutions - Aier Machinery Hebei Co., Ltd.

NewsAug.06,2025

-

Small Dredger-Marine Pontoon|Gold Dredging Boat&Marine Pump

NewsAug.06,2025

-

Top Submersible Well Pump Manufacturer | China Factory

NewsAug.06,2025

-

Small Dredger and Marine Pontoon - Aier Machinery | Dredging Solutions, Waterway Management

NewsAug.05,2025

-

Small Dredger and Marine Pontoon - Aier Machinery | Gold Mining Equipment, Industrial Dredging Systems

NewsAug.05,2025

-

Small Dredger and Marine Pontoon- Aier Machinery Hebei Co., Ltd|Cost-Effective Solutions&High-Efficiency Dredging

NewsAug.05,2025