Jan . 11, 2025 09:41 Back to list

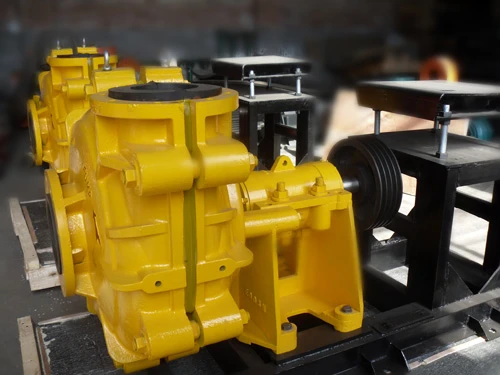

slurry pump casing

Slurry pump casings play an integral role in the effective and efficient operation of slurry pumps, which are widely used across various industries, from mining to chemical processing. At first glance, the outer shell of these pumps seems simple, but a deeper understanding reveals a blend of engineering mastery, material science, and operational acumen. These casings are not merely protective shells; they are the critical components that ensure optimal performance under demanding conditions.

Authority in the field of slurry pump casings comes from rigorous testing and a track record of performance in the field. Manufacturers often put their casings through exhaustive trials that simulate operating conditions to ensure that their products can meet the required standards. These tests, combined with certifications from recognized industry bodies, elevate a producer’s credibility. Brands that regularly publish case studies, highlighting their implementations and the resultant benefits to the industry, further cement their status as authoritative voices in slurry pump technology. Trustworthiness in this context is built on transparency and customer support. Companies that offer detailed technical support, including installation guides, maintenance tips, and troubleshooting advice, are valued for their commitment to customer satisfaction. Service teams with established reputations for after-sales support ensure that any operational issues are swiftly addressed, fostering trust with clients. Furthermore, honesty regarding the capabilities and limitations of a slurry pump casing helps in setting realistic expectations and establishing long-term customer relationships. In conclusion, selecting the right slurry pump casing is a process that requires nuanced understanding and practical expertise. The interplay of materials science, engineering precision, performance testing, and customer service culminates in a product that meets the high demands of slurry pumping applications. Whether you're an engineer seeking to optimize your operations or a decision-maker choosing the right equipment vendor, the importance of experienced, expert, authoritative, and trustworthy guidance cannot be overstated. Each casing is not just a component; it is a promise of efficiency and resilience in challenging operational environments.

Authority in the field of slurry pump casings comes from rigorous testing and a track record of performance in the field. Manufacturers often put their casings through exhaustive trials that simulate operating conditions to ensure that their products can meet the required standards. These tests, combined with certifications from recognized industry bodies, elevate a producer’s credibility. Brands that regularly publish case studies, highlighting their implementations and the resultant benefits to the industry, further cement their status as authoritative voices in slurry pump technology. Trustworthiness in this context is built on transparency and customer support. Companies that offer detailed technical support, including installation guides, maintenance tips, and troubleshooting advice, are valued for their commitment to customer satisfaction. Service teams with established reputations for after-sales support ensure that any operational issues are swiftly addressed, fostering trust with clients. Furthermore, honesty regarding the capabilities and limitations of a slurry pump casing helps in setting realistic expectations and establishing long-term customer relationships. In conclusion, selecting the right slurry pump casing is a process that requires nuanced understanding and practical expertise. The interplay of materials science, engineering precision, performance testing, and customer service culminates in a product that meets the high demands of slurry pumping applications. Whether you're an engineer seeking to optimize your operations or a decision-maker choosing the right equipment vendor, the importance of experienced, expert, authoritative, and trustworthy guidance cannot be overstated. Each casing is not just a component; it is a promise of efficiency and resilience in challenging operational environments.

Next:

Latest news

-

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

NewsAug.04,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025