jan . 11, 2025 09:53 Back to list

slurry pump impeller

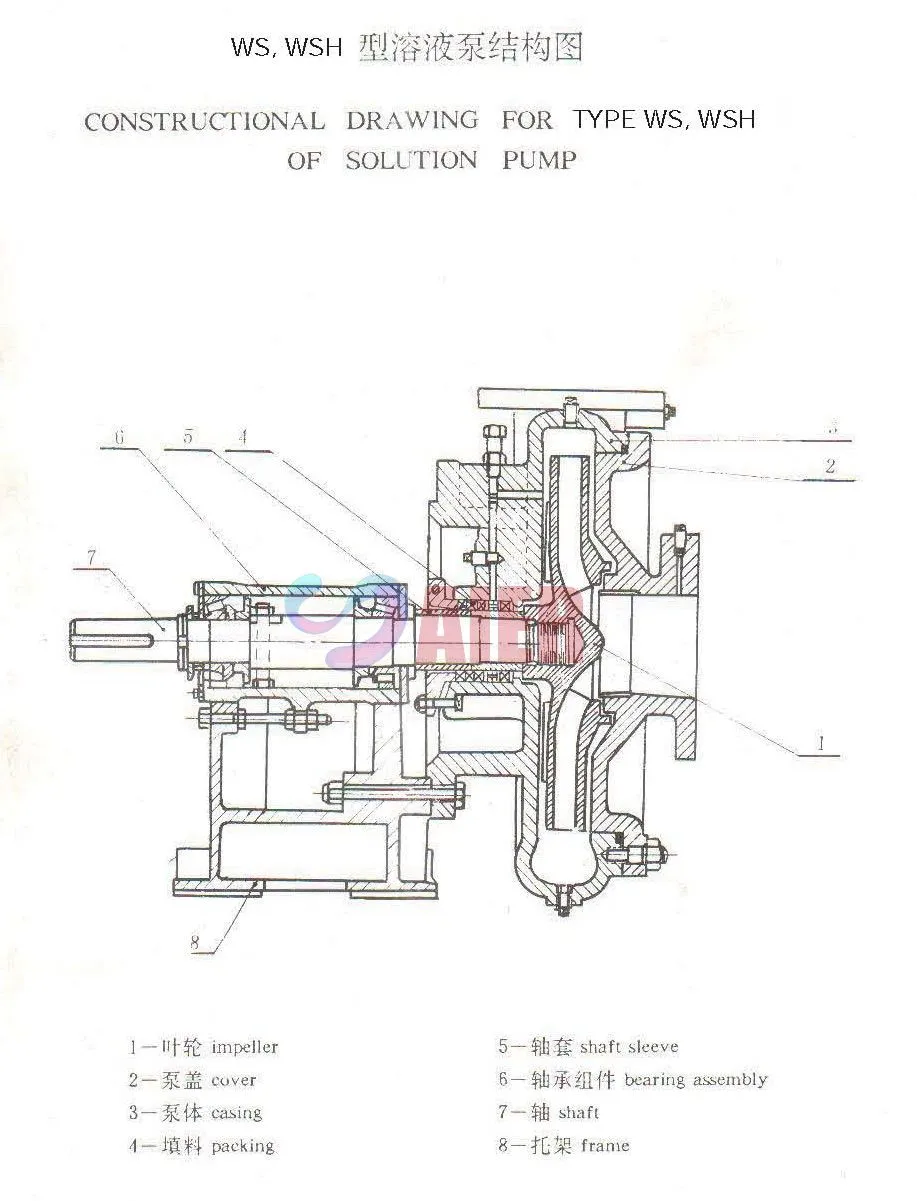

Slurry pump impellers are critical components in industries ranging from mining to wastewater management. Their design and function significantly influence the efficiency and durability of slurry pumps, which move viscous and abrasive materials. Selecting the correct slurry pump impeller entails understanding several key principles and requires a balance of technical expertise and practical experience.

When considering trustworthiness, manufacturers who provide comprehensive performance data, backed by real-world testing, inspire the most confidence. Documentation that details how an impeller performs in distinct scenarios, such as corrosive environments or under varying temperature conditions, aids in establishing a trustworthy profile for the product. Furthermore, warranties that cover material defects and performance guarantees serve as endorsements of a manufacturer’s confidence in their product’s quality and reliability. The practical experience also implies a rigorous consideration of installation and maintenance practices. Selecting an impeller is just the first step; ensuring its optimal function over time requires adhering to best practices in installation, alignment, and maintenance procedures. Regular inspections for wear and timely replacements of worn parts can prevent catastrophic failures, thereby securing the continuity of operations. Sharing case studies and technical whitepapers showcasing how specific impeller designs have successfully met particular challenges adds to the resource database of professionals in this industry. Such documentation not only enhances professional knowledge but functions as substantial proof for decision-makers in selecting the right impeller for their needs. For businesses aiming to enhance their search engine optimization (SEO) strategy, extensive content covering insights from industry experts, material analysis, testing outcomes, and real-world applications will serve to establish the company as an authority on slurry pump impellers. This approach attracts informed customers who value in-depth, quality information and are likely to engage in product offerings from a trusted and authoritative source.

When considering trustworthiness, manufacturers who provide comprehensive performance data, backed by real-world testing, inspire the most confidence. Documentation that details how an impeller performs in distinct scenarios, such as corrosive environments or under varying temperature conditions, aids in establishing a trustworthy profile for the product. Furthermore, warranties that cover material defects and performance guarantees serve as endorsements of a manufacturer’s confidence in their product’s quality and reliability. The practical experience also implies a rigorous consideration of installation and maintenance practices. Selecting an impeller is just the first step; ensuring its optimal function over time requires adhering to best practices in installation, alignment, and maintenance procedures. Regular inspections for wear and timely replacements of worn parts can prevent catastrophic failures, thereby securing the continuity of operations. Sharing case studies and technical whitepapers showcasing how specific impeller designs have successfully met particular challenges adds to the resource database of professionals in this industry. Such documentation not only enhances professional knowledge but functions as substantial proof for decision-makers in selecting the right impeller for their needs. For businesses aiming to enhance their search engine optimization (SEO) strategy, extensive content covering insights from industry experts, material analysis, testing outcomes, and real-world applications will serve to establish the company as an authority on slurry pump impellers. This approach attracts informed customers who value in-depth, quality information and are likely to engage in product offerings from a trusted and authoritative source.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025