dec . 12, 2024 11:03 Back to list

high quality vertical chemical sump pump manufacturer

High-Quality Vertical Chemical Sump Pump Manufacturer

In the world of industrial processes, the efficient management of fluids is paramount. Among the various types of pumps used in industries, vertical chemical sump pumps have emerged as essential components in handling corrosive liquids and other challenging fluids. Finding a high-quality manufacturer of vertical chemical sump pumps is crucial for ensuring operational efficiency, safety, and longevity of equipment.

Understanding Vertical Chemical Sump Pumps

Vertical chemical sump pumps are designed specifically for pumping liquids from sumps, tanks, or pits. They are often constructed from materials that resist corrosion, making them ideal for handling aggressive chemicals including acids, bases, and other hazardous materials. The vertical design of these pumps allows for a compact footprint, which is advantageous in space-constrained environments. This design also reduces the risk of leaks, as the pump is submerged in the liquid it is meant to pump.

Key Features of High-Quality Pumps

1. Material Composition The materials used in constructing a sump pump significantly impact its durability and efficiency. A high-quality vertical chemical sump pump manufacturer will use advanced materials like stainless steel, polypropylene, and other corrosion-resistant materials to ensure longevity in harsh chemical environments.

2. Performance Performance metrics such as flow rate, head, and efficiency are vital when evaluating pumps. High-quality manufacturers provide pumps that not only meet industry standards but also offer flexible operation under varying conditions. The design of their pumps should allow for optimal performance while minimizing energy consumption.

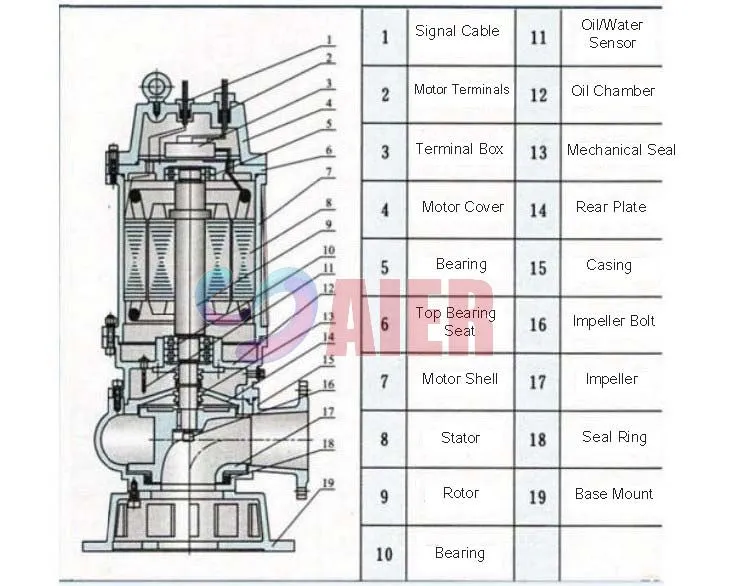

3. Sealing Technology Since these pumps deal with hazardous liquids, innovative sealing technologies are crucial. Reliable manufacturers apply advanced sealing solutions to prevent leaks and protect the integrity of the pump and surrounding environment. Mechanical seals made from durable materials can offer enhanced protection against chemical exposure.

high quality vertical chemical sump pump manufacturer

4. Customization Every industrial process is unique, and so are the fluid handling requirements. A reputable manufacturer should offer customization options, allowing clients to specify dimensions, materials, and configurations tailored to their specific needs.

5. Quality Assurance A notable characteristic of top manufacturers is their commitment to quality assurance protocols. They conduct rigorous testing, including pressure tests, performance tests, and operational simulations, to ensure that each pump meets high standards before it reaches the customer.

6. Technical Support and Service Post-purchase support is another hallmark of high-quality manufacturers. Providing comprehensive technical assistance and service can make a significant difference in the pump’s operational success. Manufacturers should offer quick access to spare parts and maintenance services to ensure minimal downtime.

Why Choose a High-Quality Manufacturer?

Opting for a high-quality manufacturer of vertical chemical sump pumps provides several long-term benefits. First and foremost, these pumps typically have lower total operating costs due to their efficiency and durability. An investment in a high-quality pump reduces the frequency of replacements and repairs, allowing companies to allocate financial resources more effectively.

Moreover, high-quality manufacturers often follow strict industry standards and regulations, ensuring that their products are compliant with safety and environmental guidelines. This compliance not only protects workers and the environment but also enhances the company's reputation and market standing.

Conclusion

Selecting the right vertical chemical sump pump manufacturer can have a profound impact on operational effectiveness and safety in chemical handling processes. By prioritizing quality, performance, customization, and comprehensive support, organizations can secure a reliable solution to their fluid management challenges. As industries continue to evolve, the need for robust, high-quality pumping solutions will remain a cornerstone of successful operations. Investing in reputable manufacturers not only ensures peace of mind but also lays the groundwork for sustainable growth and innovation in any chemical handling application.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025