Lis . 05, 2024 12:33 Back to list

industrial slurry pump

Understanding Industrial Slurry Pumps Key Features and Applications

Industrial slurry pumps are essential components in various industrial processes, particularly in mining, construction, and wastewater management. These pumps are designed to handle abrasive and viscous materials, making them crucial for transporting mixtures of liquid and solid particles. This article delves into the key features, benefits, and applications of industrial slurry pumps, showcasing their importance in modern industrial operations.

Key Features of Industrial Slurry Pumps

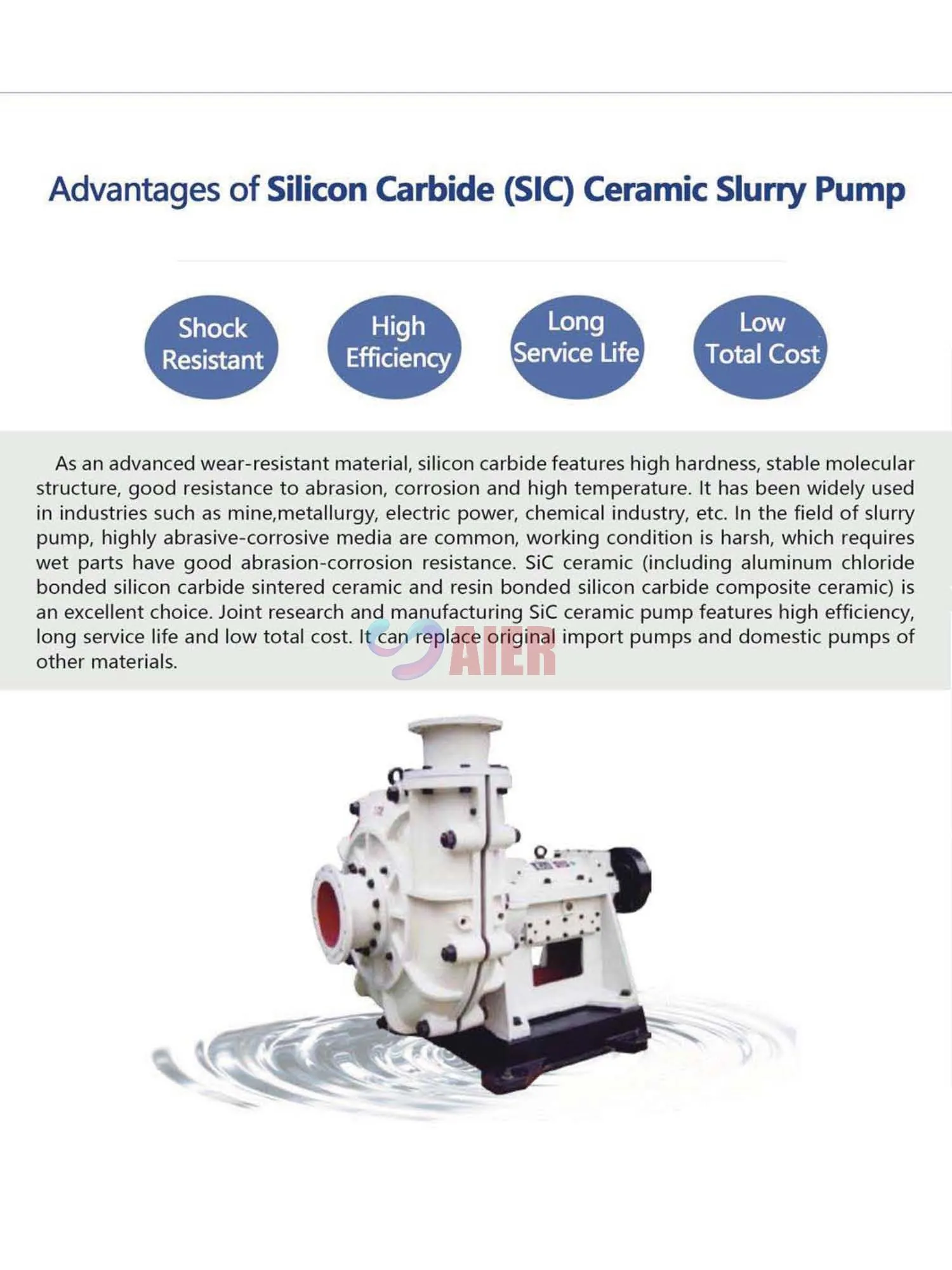

1. Robust Construction Industrial slurry pumps are built to withstand harsh conditions. They are typically constructed from durable materials such as high-chrome alloys, rubber, or even ceramic linings. This robust construction allows them to resist wear and tear from the abrasive nature of the slurries they transport.

2. High Efficiency These pumps are engineered for maximum efficiency. Their design facilitates the movement of large volumes of slurry with minimal energy consumption. This is particularly important in large-scale operations where energy costs can significantly impact overall expenses.

3. Versatility Slurry pumps can handle a wide range of slurries, including those with varying densities and particle sizes. This versatility makes them suitable for different applications, from transporting tailings in mining to handling sludge in wastewater treatment plants.

4. Self-Priming Capability Many industrial slurry pumps feature self-priming mechanisms that allow them to start pumping without needing to be manually primed with fluid. This feature saves time and labor, ensuring a more efficient operation.

5. Variable Speed Options Modern slurry pumps can operate at different speeds, allowing for greater control over the flow rate. This adaptability is particularly useful in processes where the consistency of the slurry may change.

Benefits of Using Industrial Slurry Pumps

1. Cost-Effectiveness Although the initial investment in industrial slurry pumps may be significant, their durability and efficiency lead to lower maintenance costs and reduced operational downtime, ultimately resulting in long-term savings.

industrial slurry pump

2. Increased Productivity By providing reliable and continuous transportation of slurries, these pumps ensure that industrial processes run smoothly. This reliability translates to increased productivity and efficiency across operations.

3. Enhanced Safety Industrial slurry pumps are designed with safety features that reduce the risk of spills or leaks. This is crucial in environments where hazardous materials are handled, minimizing workplace accidents and environmental impact.

4. Improved Process Control The ability to adjust flow rates and pressure settings allows for better control over the slurry handling process, leading to optimized performance and product quality.

Applications of Industrial Slurry Pumps

1. Mining Operations One of the primary applications of slurry pumps is in the mining industry, where they transport ore slurry, tailings, and other materials. The ability to manage large volumes of abrasive materials makes them indispensable in this sector.

2. Wastewater Treatment Industrial slurry pumps are also used in wastewater treatment facilities to handle sludge and other waste materials. Their efficient pumping capabilities help in the effective treatment of wastewater, leading to cleaner effluents.

3. Construction Industry In construction, these pumps are used for dewatering and transporting various mixtures of cement, sand, and water. Their durability ensures that they can handle the challenging conditions often present at construction sites.

4. Chemical Processing In chemical manufacturing, slurry pumps facilitate the movement of chemical slurries that contain both solids and liquids. They ensure that processes are completed efficiently and safely.

Conclusion

Industrial slurry pumps play a vital role in numerous industries, ensuring that operations run smoothly while handling abrasive and viscous materials. Their robust construction, efficiency, and versatility make them an invaluable asset in mining, wastewater treatment, construction, and chemical processing. As industries continue to evolve, the importance of reliable slurry pumps in promoting productivity and safety remains paramount. Understanding their features and applications provides businesses with the knowledge necessary to optimize their operations and enhance overall performance.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025