Nov . 21, 2024 03:40 Back to list

slurry pump for vapour blasting factories

The Role of Slurry Pumps in Vapour Blasting Factories

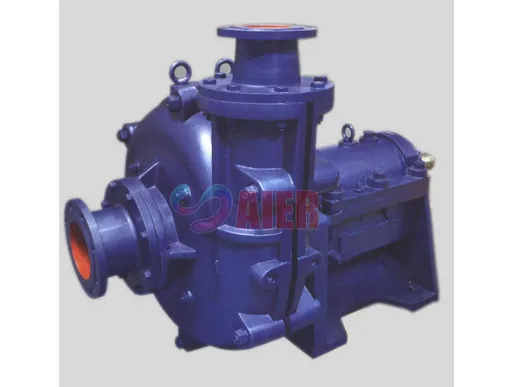

In the realm of industrial cleaning and surface preparation, vapour blasting has emerged as a favored technique. This method utilizes a mixture of abrasive materials and water vapor to effectively clean and finish surfaces, making it ideal for various applications, including automotive, aerospace, and marine industries. Central to the efficacy of this process is the slurry pump, which plays a critical role in delivering the abrasive mixture consistently and efficiently.

A slurry pump is designed to handle mixtures of solids and liquids—specifically, the wet abrasive slurry used in vapour blasting. The uniqueness of this pump lies in its robust construction, enabling it to endure the wear and tear that comes from transporting abrasive materials. Additionally, the pump is engineered to maintain a consistent flow rate, ensuring that the blasting process remains smooth and efficient.

One of the primary advantages of using a slurry pump in a vapour blasting factory is its ability to manage varying particle sizes and types of abrasives. Whether it’s glass beads, garnet, or aluminum oxide, a high-quality slurry pump can accommodate a wide range of materials, providing flexibility for different cleaning tasks. This adaptability is crucial as it allows manufacturers to select the best abrasive for specific applications, ensuring optimal surface finishes.

slurry pump for vapour blasting factories

Moreover, slurry pumps help in minimizing downtime in vapour blasting operations

. With their durable design and efficient performance, these pumps require less frequent maintenance compared to standard pumps. This reliability translates to increased productivity, as machines can operate longer without interruptions.Environmental considerations also play a significant role in the discussion of slurry pumps in vapour blasting. By effectively recycling the abrasive materials and reducing waste, these pumps contribute to greener manufacturing processes. The ability to reuse abrasives not only cuts costs but also aligns with modern sustainability goals.

In conclusion, slurry pumps are an indispensable component of vapour blasting factories. Their robust design, adaptability to different abrasives, and efficient operation contribute to the overall effectiveness of the vapour blasting process. As industries continue to seek advanced cleaning solutions, the role of slurry pumps will only become more prominent, ensuring that vapour blasting remains a leading choice for surface preparation.

-

High-Quality Sand Suction Dredge Pump Factories Durable & Efficient

NewsMay.22,2025

-

High-Quality Interchangeable Slurry Pump Spare Parts Supplier China

NewsMay.22,2025

-

China Gravel Dredge Pump - Heavy-Duty Slurry & Sand Dredging

NewsMay.22,2025

-

Durable Centrifugal Wastewater Pumps China Abrasives Pump Suppliers

NewsMay.21,2025

-

High-Quality Horizontal Centrifugal Slurry Pump China Factory & Supplier

NewsMay.21,2025

-

China Slurry Pump Rubber Parts - Durable & Custom Solutions

NewsMay.20,2025