Dis . 12, 2024 10:42 Back to list

high quality slurry pump impeller wear manufacturers

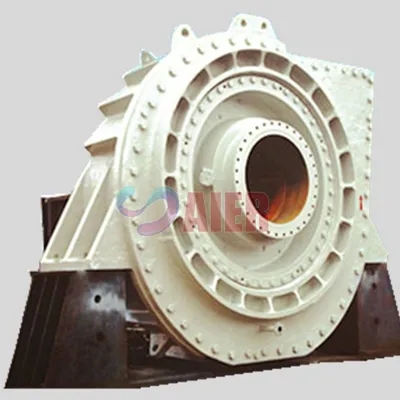

High-Quality Slurry Pump Impeller Wear Manufacturers

In the industrial landscape, slurry pumps play a pivotal role in a variety of sectors such as mining, minerals processing, and wastewater treatment. Their primary function is to transport slurries—mixtures of liquid and solid particles—efficiently. However, one of the most significant challenges faced by these pumps is impeller wear, which can drastically affect their performance and lifespan. This article delves into the importance of high-quality slurry pump impeller wear manufacturers and their contributions to enhancing pump efficiency and reliability.

Understanding Impeller Wear

Impeller wear occurs primarily due to the erosive nature of the slurries being pumped. The solid particles in the slurry can cause abrasion on the impeller surfaces, leading to reduced pump efficiency and increased maintenance costs. The rate of wear depends on various factors including the particle size, density, velocity of the slurry, and the material composition of the impeller itself. Therefore, choosing the right manufacturer that specializes in durable and high-quality components is crucial for maintaining optimal performance and ensuring the longevity of the slurry pump.

Role of High-Quality Manufacturers

High-quality slurry pump impeller wear manufacturers focus on developing products that can withstand harsh operational conditions. They utilize advanced materials and cutting-edge technologies to produce impellers that can resist wear over extended periods. Some of the key characteristics of high-quality impellers include

1. Material Selection Quality manufacturers often use materials with high abrasion resistance, such as high chrome alloys, rubber linings, and various composite materials. These materials are specifically engineered to endure the erosive forces encountered in slurry pumping applications.

2. Engineering Expertise Leading manufacturers invest in engineering research and design, employing skilled professionals who understand the complexities of fluid dynamics and materials science. This expertise allows them to create innovative designs that minimize wear while maximizing hydraulic performance.

high quality slurry pump impeller wear manufacturers

3. Testing and Quality Control Before their products reach the market, high-quality manufacturers conduct rigorous testing. This includes wear testing under simulated operating conditions to ensure that their impellers maintain performance expectations over time. Quality control measures help identify potential weaknesses and provide solutions that enhance product reliability.

4. Custom Solutions Different industries and applications have unique requirements. Reputable manufacturers offer tailored solutions, providing custom-made impellers designed to suit specific slurry compositions and operational conditions. This customization enhances longevity and efficiency, reducing operational downtime.

Benefits of High-Quality Impellers

Investing in high-quality slurry pump impeller wear components yields numerous benefits. Firstly, it leads to reduced maintenance costs. When pumps operate efficiently with less wear, the frequency of repairs and replacements diminishes, translating into significant savings for companies involved in heavy-duty operations.

Secondly, improved efficiency is a direct advantage. High-quality impellers provide optimal flow characteristics, enabling pumps to move slurries at higher capacities and with lower energy consumption. This not only results in cost savings but also promotes sustainability, aligning with industries striving for reduced environmental impact.

Lastly, the longevity of the pump system is greatly enhanced. By minimizing wear rates, high-quality impellers contribute to extending the operational life of the entire pumping system. This reliability is particularly crucial in critical applications such as mineral extraction and wastewater management, where unplanned equipment failures can lead to substantial financial losses and operational setbacks.

Conclusion

The role of high-quality slurry pump impeller wear manufacturers cannot be overstated. They provide crucial resources that enhance the efficiency, reliability, and lifespan of pumps across various industries. By focusing on advanced materials, engineering expertise, rigorous testing, and customized solutions, these manufacturers ensure that businesses can operate smoothly despite the challenges posed by abrasive slurries. Ultimately, investing in high-quality impellers is an investment in efficiency, cost savings, and operational sustainability in today’s competitive industrial environment.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025