лют . 15, 2025 12:16 Back to list

wholesale slurry pump spare parts rubber parts

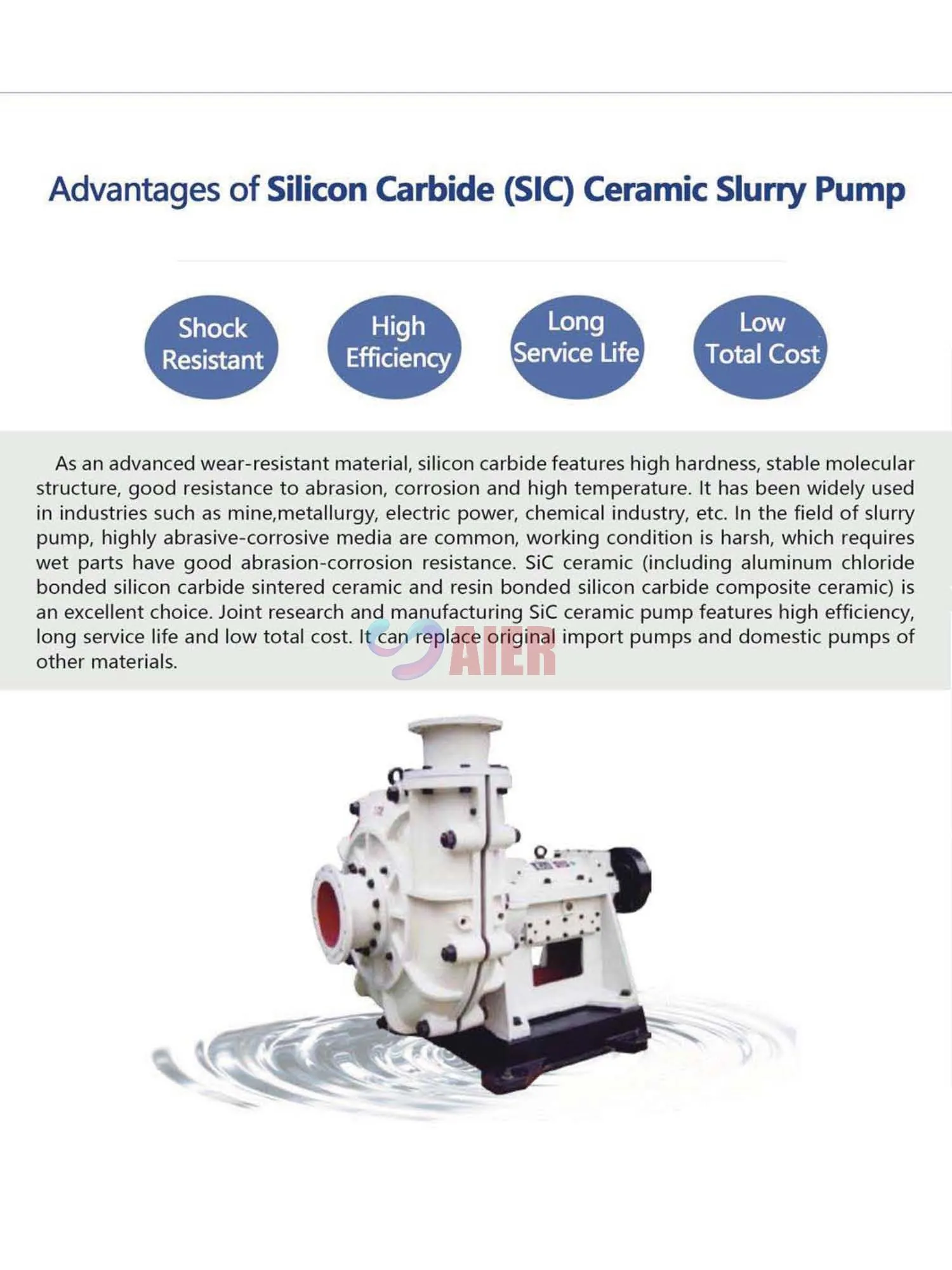

When it comes to maintaining the efficiency and longevity of industrial machinery, few components play as critical a role as the slurry pump and its spare parts. Industries relying on slurry pumps—ranging from mining to wastewater management—understand that the quality of exchangeable spare parts can significantly impact operational performance and cost-efficiency. Slurry pumps are engineered to handle abrasive, viscous, and volatile materials, which means the wear and tear on these components can be considerable.

In terms of trustworthiness, direct customer testimonials and case studies are invaluable. Customers who have faced similar operational challenges and have found solutions through high-quality slurry pump spare parts can provide insights into product reliability and performance under comparable conditions. Trust is further built through transparency in the sourcing of materials, manufacturing processes, and warranty policies, all of which should be openly communicated by reputable suppliers. A critical consideration for any business is cost-effectiveness. While high-quality exchangeable slurry pump spare parts might initially have a higher price point, their durability and reliability often translate to savings in the long run. Reduced maintenance and replacement frequency not only minimize downtime but also lower overall operational costs, presenting a compelling case for investing in superior quality components. In an increasingly digital marketplace, finding the right slurry pump spare parts supplier involves more than just a quick online search. Online presence, customer support availability, and ease of navigating product catalogs online are part of the trust-building process. Suppliers that provide detailed product information, responsive customer service, and technical support online set themselves apart as customer-centric businesses. In conclusion, the advantages of investing in high-quality exchangeable slurry pump spare parts span beyond immediate functional improvements to include long-term operational efficiency and cost savings. Companies that prioritize quality, customization, authority, and trust in their selection of slurry pump spare parts position themselves for enhanced productivity and competitive advantage.

In terms of trustworthiness, direct customer testimonials and case studies are invaluable. Customers who have faced similar operational challenges and have found solutions through high-quality slurry pump spare parts can provide insights into product reliability and performance under comparable conditions. Trust is further built through transparency in the sourcing of materials, manufacturing processes, and warranty policies, all of which should be openly communicated by reputable suppliers. A critical consideration for any business is cost-effectiveness. While high-quality exchangeable slurry pump spare parts might initially have a higher price point, their durability and reliability often translate to savings in the long run. Reduced maintenance and replacement frequency not only minimize downtime but also lower overall operational costs, presenting a compelling case for investing in superior quality components. In an increasingly digital marketplace, finding the right slurry pump spare parts supplier involves more than just a quick online search. Online presence, customer support availability, and ease of navigating product catalogs online are part of the trust-building process. Suppliers that provide detailed product information, responsive customer service, and technical support online set themselves apart as customer-centric businesses. In conclusion, the advantages of investing in high-quality exchangeable slurry pump spare parts span beyond immediate functional improvements to include long-term operational efficiency and cost savings. Companies that prioritize quality, customization, authority, and trust in their selection of slurry pump spare parts position themselves for enhanced productivity and competitive advantage.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025