Каст . 13, 2024 04:28 Back to list

Top Manufacturers of Premium Diesel Slurry Pumps for Efficient Industrial Applications

High-Quality Diesel Slurry Pump Manufacturers Key Players in the Industry

In the modern industrial landscape, the demand for efficient and reliable pumping solutions has increased significantly. Among these solutions, diesel slurry pumps have emerged as essential equipment for various sectors such as mining, construction, and wastewater management. The effectiveness of these pumps largely depends on the quality and reliability of their manufacturing. This article explores the importance of high-quality diesel slurry pump manufacturers and highlights some key players in the industry.

Understanding Diesel Slurry Pumps

Diesel slurry pumps are specially designed to handle abrasive and viscous materials, making them ideal for transporting slurries in challenging environments. These pumps operate using a diesel engine, which provides robust performance and operational flexibility in remote locations where electricity supply may be limited. The ability to pump heavy slurries at varying flow rates, coupled with their durability and efficiency, makes diesel slurry pumps indispensable in many applications.

Crucial Factors in Selecting a Manufacturer

When selecting a manufacturer for diesel slurry pumps, several crucial factors come into play

1. Quality of Materials High-quality manufacturers use premium materials that resist wear and corrosion. This is critical, as slurry transport often involves abrasive particles that can quickly degrade substandard pumps.

2. Design Innovation The design of the pump significantly impacts its efficiency and longevity. Innovative designs that optimize hydraulic performance can lead to better energy consumption and reduced operational costs.

3. Customization Options Every industrial application is unique, requiring specific configurations. Reputable manufacturers often offer customization options that cater to specific needs, ensuring the pump's effectiveness in various conditions.

4. After-Sales Service A strong after-sales service is essential for the maintenance and longevity of diesel slurry pumps. High-quality manufacturers typically provide comprehensive support, including installation, maintenance, and troubleshooting.

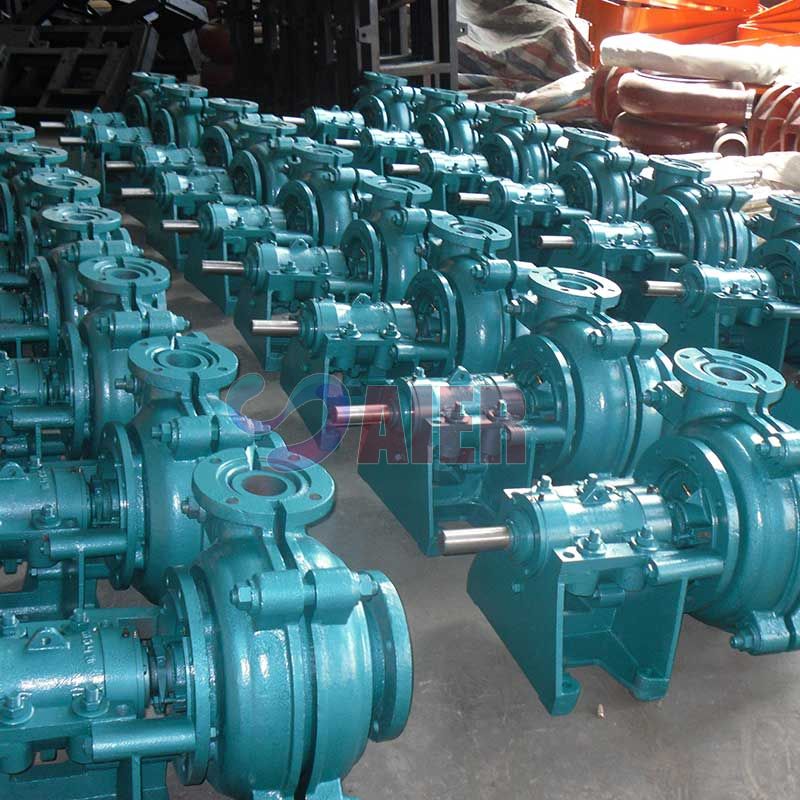

high quality diesel slurry pump manufacturers

5. Industry Reputation Trusted manufacturers often have a proven track record in the industry. Customer reviews, case studies, and industry certifications can provide valuable insights into a manufacturer's reputation.

Leading Diesel Slurry Pump Manufacturers

Several manufacturers have distinguished themselves in the production of high-quality diesel slurry pumps. Here are a few notable names

1. Weir Group With a long history in engineering and manufacturing, Weir Group is renowned for its high-performance slurry pumps. Their products are built to withstand the harshest conditions found in mining and heavy industrial applications.

2. Goulds Pumps (A Xylem Brand) Goulds Pumps offers a variety of industrial pumps, including diesel slurry pumps. Their commitment to innovation and quality makes them a preferred choice in multiple sectors.

3. Schurco Slurry Specializing in slurry pumps, Schurco Slurry provides a range of solutions designed to handle the most demanding applications. Their focus on customer service and product reliability has established them as a key player in the market.

4. Centrifugal Pump Manufacturer (CPM) CPM is known for producing high-quality centrifugal and diesel slurry pumps. Their commitment to research and development has led to various innovative products that enhance efficiency and performance.

5. Grindex Grindex manufactures drainage and slurry pumps that are built for tough environments. Their robust design and operational efficiency are well-regarded in industries such as construction and mining.

Conclusion

The importance of selecting a high-quality diesel slurry pump manufacturer cannot be overstated. As industries seek efficient and reliable pumping solutions, manufacturers who prioritize quality, innovation, and customer support will continue to lead the market. By investing in top-tier diesel slurry pumps, businesses can ensure operational efficiency, reduce downtime, and ultimately enhance their productivity in an increasingly competitive environment.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025