студ . 06, 2025 18:54 Back to list

OEM Castings

Fluid gas desulfurization pumps, commonly referred to as FGD pumps, are a pivotal component in environmental and industrial applications. Their role in the reduction of sulfur dioxide emissions from coal-fired power plants exemplifies the intersection of engineering ingenuity and environmental stewardship.

FGD pumps are specifically designed to handle the abrasive and corrosive slurry mixtures that are a byproduct of the flue gas desulfurization process. This process, crucial in mitigating air pollution, involves the removal of sulfur pollutants from exhaust gases produced by fossil fuel combustion. As such, the design and functionality of FGD pumps must be robust to endure the harsh conditions they encounter.

Experience with using FGD pumps highlights the importance of material selection, as the pumps often face highly acidic environments. Users often report that the most reliable pumps are those constructed from high-grade stainless steel or specialized alloys that provide resistance against acid corrosion. Furthermore, linings made from rubber or other synthetic materials offer an additional layer of defense against wear and tear, contributing to the longevity of the pump.

From a professional standpoint, the expertise required to properly manage and maintain FGD pumps cannot be underestimated. Experts in the field recommend regular maintenance checks and monitoring, utilizing advanced technologies such as vibration analysis and thermography to detect early signs of wear or failure. Implementing a predictive maintenance strategy can significantly extend the lifespan of these pumps and ensure continuous, efficient operations.

Authorities in environmental regulations continually emphasize the necessity of utilizing efficient FGD systems in industrial settings. Compliance with governmental standards, such as those set by the Environmental Protection Agency (EPA) in the United States, necessitates that companies invest in high-quality FGD pumps. These pumps not only meet regulatory requirements but also reflect a commitment to sustainable practice.

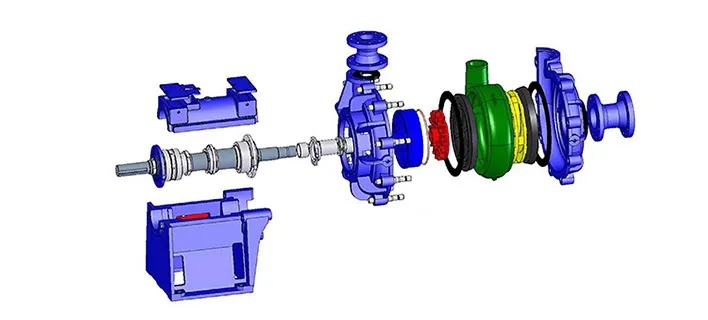

fgd pump

Trust in the manufacturers of FGD pumps is built upon proven performance and reliability. Industry leaders in pump manufacturing provide comprehensive support and extensive warranties, which enhance consumer confidence. It's essential that manufacturers maintain transparency about the capabilities of their products and operate within the frameworks of environmental and safety regulations to assure customers of their reliability.

In product considerations, choosing the right FGD pump involves evaluating several critical factors such as flow rate, pressure requirements, and the specific chemical composition of the slurry being handled. The complexity of the selection process underscores the importance of consulting with specialists who possess a deep understanding of fluid dynamics and material science.

Future advancements in FGD pump technology are expected to focus on enhancing energy efficiency and reducing operational costs. Innovations such as the integration of smart sensors for real-time monitoring and automated adjustment features promise to optimize performance and minimize downtime. As technology progresses, staying informed about these developments is essential for any company reliant on effective sulfur dioxide reduction solutions.

In essence, FGD pumps are not merely components within an industrial setup; they are linchpins in the broader effort to reduce environmental impact. Their continuous evolution in design and application reflects an ongoing commitment to cleaner air and a healthier planet. Whether through rigorous maintenance, adherence to regulations, or the adoption of cutting-edge technology, the journey toward better FGD systems is both a technical challenge and an opportunity for ecological advancement.

-

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

NewsAug.04,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025