centrifugal slurry pump liner supplier

Latest articles

Selecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreSump drainage or washdown

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreConveying medium

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreA , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreQuenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreSlurry Pump

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreThe selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read More- Low noise level - Operating underwater results in low noise or even silent operation.

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

centrifugal slurry pump liner supplier...

centrifugal slurry pump liner supplier 【centrifugal slurry pump liner supplier】

Read More

Popular articles

- Metal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

- Slurry Pump

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

- The company uses advanced computer assistant engineering software to design products and technology, which makes our

- Includes a large number of solids or particles.

Latest articles

-

When slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

-

Non-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

-

What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

Links

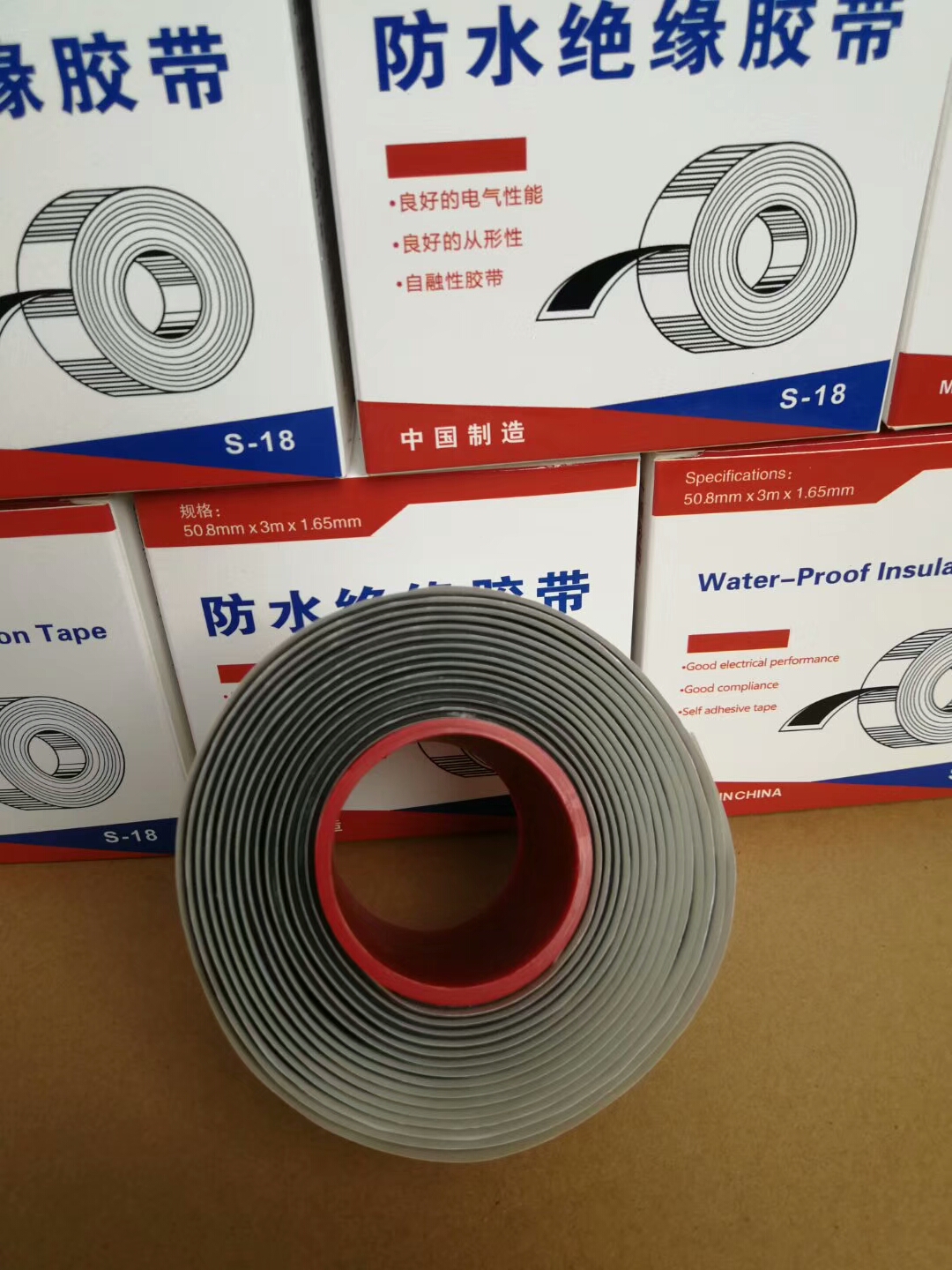

- One of the key advantages of PVC tape is its high dielectric strength, which ensures that it can withstand high voltage without breaking down. This makes it an ideal choice for insulating wires, cables, and other electrical components in both indoor and outdoor settings. Whether you're working on residential or commercial projects, PVC tape provides the necessary protection against electric shock and short circuits.

- PVC Floor Masking Tape An Indispensable Tool for Home Renovation

Electrical tape is used to protect against electrical shock and short circuits.

- PVC, or Polyvinyl Chloride, has emerged as a staple material in the realm of electrical insulation due to its remarkable properties and versatility. This synthetic plastic polymer, commonly known as PVC tape insulation, plays a pivotal role in ensuring safety and efficiency in various electrical applications.

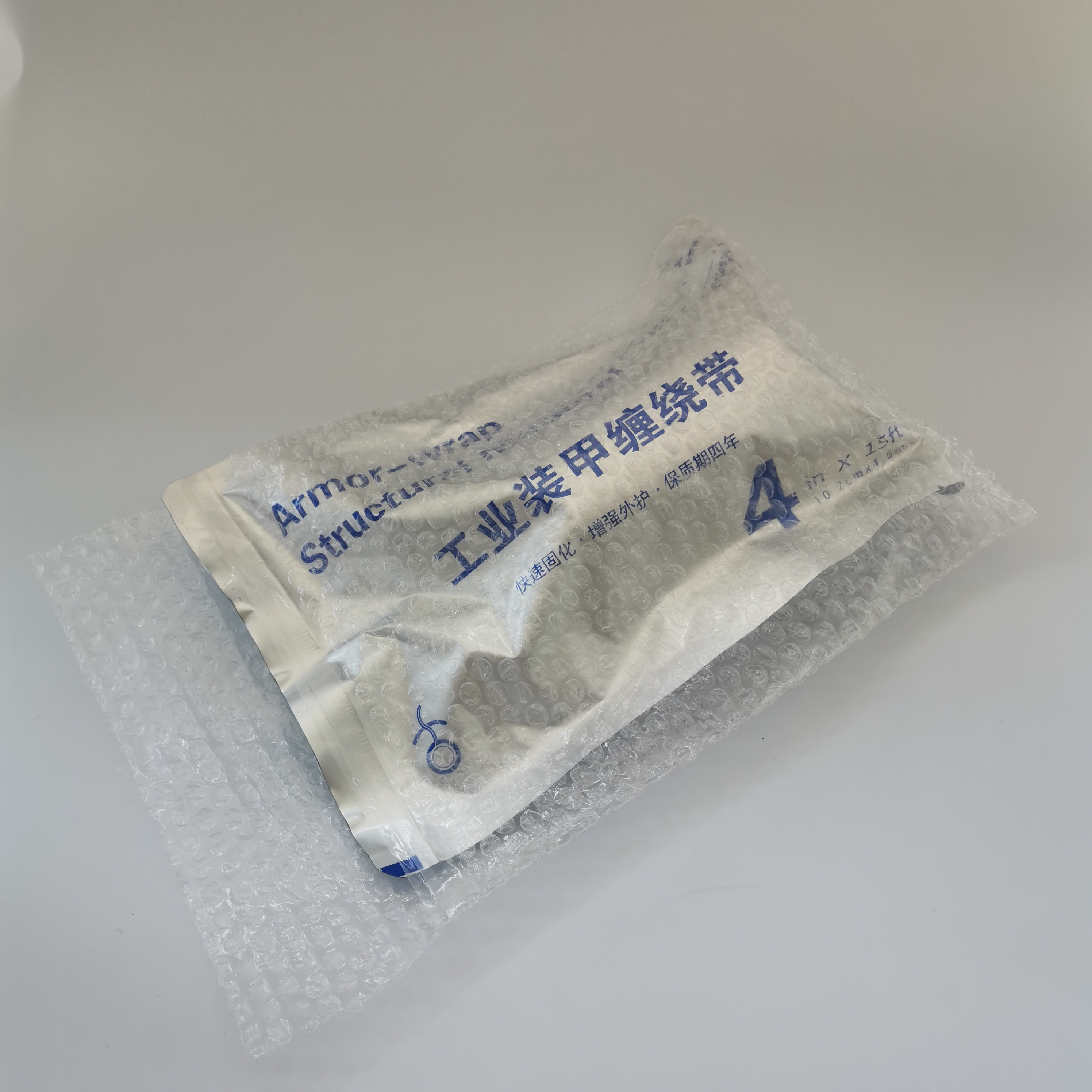

- In addition to its practical applications, vulcanizing tape is also cost-effective. Because it can be used for a wide range of repairs and does not require frequent replacement, vulcanizing tape can save time and money in the long run. Its durability and reliability also contribute to reducing the need for costly replacements or repairs down the line.

- The term butyl refers to the primary adhesive component, a synthetic rubber known for its excellent sealing and bonding properties. It is renowned for its flexibility, conformability, and ability to adhere to a wide range of surfaces, including wet and uneven ones. On the other hand, the foil component, typically aluminum or copper, provides the tape with its durability, heat resistance, and barrier properties against water, air, and UV radiation.

- Insulation black tape is available in different widths and thicknesses, allowing users to choose the perfect size for their specific application. Its easy-to-use nature makes it a popular choice among professionals who require a quick and convenient solution for insulation tasks.

- Butyl rubber adhesive tape is a versatile and popular material known for its strong adhesion and weather resistance properties. It is commonly used in various industries for sealing, insulation, and bonding applications. The tape is made of synthetic rubber known as butyl rubber, which has excellent adhesion to a wide range of surfaces.

- The primary function of weatherstrip seals is to seal gaps and cracks around doors, windows, and other openings. This helps to minimize heat loss during winter and prevent excessive heat gain in summer, thereby reducing the workload on heating and cooling systems. As a result, energy consumption and associated costs are significantly lowered, making weatherstripping an effective and cost-efficient method for improving a building's energy efficiency.

Automotive enthusiasts also appreciate the benefits of amalgamating rubber tape. It can be used to seal and protect electrical connections, repair hoses and hoses, and even temporarily fix exhaust leaks. Its durability and resistance to oils and fuels make it a reliable solution for various automotive maintenance and repair tasks.

- In China, butyl rubber tape is produced by several manufacturers who adhere to strict quality control standards to ensure the tape meets the requirements of their customers. These manufacturers use advanced technology and machinery to produce high-quality butyl rubber tape that is resistant to various environmental conditions such as moisture, UV rays, and temperature fluctuations.

- In warehouses, yellow line markings streamline operations by defining storage areas, pedestrian walkways, and forklift routes. They prevent collisions, reduce accidents, and enhance overall workflow, thereby increasing productivity. The durability and resistance of these tapes against wear and tear make them ideal for high-traffic areas.

- ToughStripe Floor Tape A Durable Solution for High-Traffic Areas

- 4. Temperature Resistance It can withstand high temperatures, ranging from -40°C to 105°C, making it suitable for use in harsh automotive environments.

Where can I buy silicone tape?

In addition to its insulating properties, black PVC tape is also effective for bundling and organizing cables and wires. In environments where multiple cables are present, such as in data centers or home entertainment systems, using PVC tape to bundle wires can reduce clutter and improve aesthetics. This not only makes the workspace more visually appealing but also minimizes the risk of tangling or damage to the cables. By securing wires together, black PVC tape helps maintain a safe and organized environment.

Overall, PVC marking tape is an essential tool for efficient and effective workplace organization. It helps streamline operations, improve safety, and reduce the risk of errors or accidents. With its versatility, durability, and ease of use, PVC marking tape is a valuable asset for any industry or workplace.

Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage

Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage Then, starting at one end, wrap the tape tightly around the wire or surface, overlapping each layer by half its width to ensure complete coverage electrical pvc insulation tape. For added security, particularly in high-wear situations, an additional layer or two could be applied.

electrical pvc insulation tape. For added security, particularly in high-wear situations, an additional layer or two could be applied.The Versatility of Black Flex Tape

It has an abrasion-resistant backing that lasts long and has flexibility, which makes it a prime option for insulating electrical connections during electrical tapping.

Before ordering any type of tape, check to see what kind of adhesion it uses. The adhesive side of a tape roll, colloquially called the sticky side, commonly comes in three varieties: acrylic, hot melt, and natural rubber.

The Versatile Utility of PVC Black Tape

This characteristic makes it ideal for repairing cracks, holes, or splits in various materials, including plastic, metal, wood, rubber, and even concrete This characteristic makes it ideal for repairing cracks, holes, or splits in various materials, including plastic, metal, wood, rubber, and even concrete

This characteristic makes it ideal for repairing cracks, holes, or splits in various materials, including plastic, metal, wood, rubber, and even concrete This characteristic makes it ideal for repairing cracks, holes, or splits in various materials, including plastic, metal, wood, rubber, and even concrete