china polyurethane slurry pump factory

Latest articles

reduce the discharge pressure of the pump to the lowest possible point, and.

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreWhat are the materials used to construct the pump?

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read Moremethod and level of design reach international advanced level. The company has the first-class pump performance

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreThe selection of a dredge or , slurry pump, can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreSelecting a dredge pump

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreHow much solids damage can the customer tolerate?

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreLifetime use

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read MoreSlurry Pump

china polyurethane slurry pump factory...

china polyurethane slurry pump factory 【china polyurethane slurry pump factory】

Read More

Popular articles

- Slurry Pump Impeller Type

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- Slurry Pump

- There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

- Slurry Pump

Latest articles

-

Light-duty Slurry Pump

-

How to Choose a Dredging Pump or Slurry Pump

-

>Dredge Pump

-

- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

-

- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

-

Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

Links

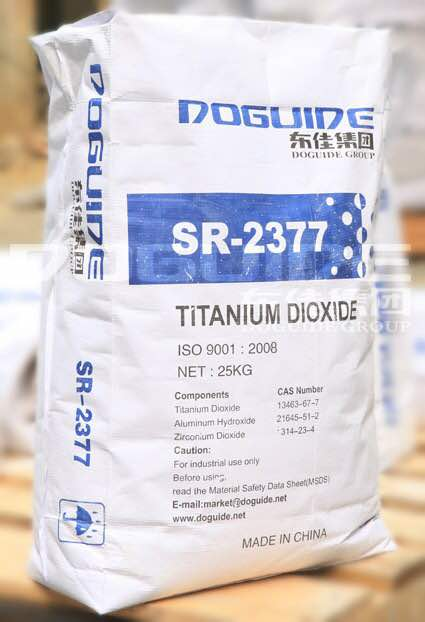

- However, China's dominance in the TiO2 sector has not been without challenges. Environmental concerns have arisen due to the energy-intensive production process, leading to stricter regulations both domestically and internationally. The industry is now under pressure to adopt cleaner and more sustainable manufacturing methods, a shift that could reshape the global titanium dioxide landscape.

Decreased Vitamin D bioaccessibility

Water solubles, %

- O2Ti's journey began with a focus on providing cost-effective and reliable industrial automation solutions to small and medium-sized enterprises (SMEs) in China. Over time, the company has expanded its offerings to include a wide range of products and services, including process control systems, robotics, and industrial software.

The compound in the Asia Pacific market experienced a mixed trends throughout the fourth quarter of 2021. These market attitudes were mostly related to lower operational loads at Chinese domestic manufacturing plants.

In terms of application, meticulous preparation and attention to detail yield the best results. For paint grinders, maintaining a ratio of 12 pounds of refined linseed oil to 88 pounds of lithopone pigment will provide optimal workability. A salient factor that should be heeded is the state of the lithopone before mixing with oil; the material must be sufficiently dry. Only then will it integrate seamlessly with the oil, ensuring that the resultant mixture possesses the desired consistency and properties.

In addition to quality, CAS 13463-67-7 also places a strong emphasis on sustainability. The factory is dedicated to reducing its environmental impact by implementing eco-friendly practices and technologies. From waste reduction to energy efficiency, CAS 13463-67-7 is constantly looking for ways to improve its sustainability and contribute to a greener future.

dye pigment cas 13463-67-7 titanium dioxide factory

Price and Availability

Price and AvailabilityThe Market Dynamics of Wholesale Titanium Dioxide

They source raw materials, adhere to strict quality control measures, and maintain consistent product specifications to meet customer demands They source raw materials, adhere to strict quality control measures, and maintain consistent product specifications to meet customer demands

They source raw materials, adhere to strict quality control measures, and maintain consistent product specifications to meet customer demands They source raw materials, adhere to strict quality control measures, and maintain consistent product specifications to meet customer demands lithopone b311 powder quotes supplier. The global market for Lithopone B311 powder is highly competitive, with suppliers striving to offer not only competitive pricing but also top-notch service, including prompt delivery and technical support.

lithopone b311 powder quotes supplier. The global market for Lithopone B311 powder is highly competitive, with suppliers striving to offer not only competitive pricing but also top-notch service, including prompt delivery and technical support.

In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany

In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany In addition to China, there are also many titanium dioxide powder factories in other countries such as the United States, Japan, and Germany titanium dioxide powder factories. These factories compete with each other in terms of product quality, price, and service to meet the needs of different customers.

titanium dioxide powder factories. These factories compete with each other in terms of product quality, price, and service to meet the needs of different customers.Assessment of skin penetration and biohazard in vivo

ponceau 4r and titanium dioxide factory. Waste management systems are rigorously enforced to minimize environmental impact. Effluent treatment facilities cleanse wastewater before it is released back into the ecosystem. Furthermore, the factory has embraced solar power initiatives, reducing its carbon footprint and contributing positively to the global effort against climate change.

ponceau 4r and titanium dioxide factory. Waste management systems are rigorously enforced to minimize environmental impact. Effluent treatment facilities cleanse wastewater before it is released back into the ecosystem. Furthermore, the factory has embraced solar power initiatives, reducing its carbon footprint and contributing positively to the global effort against climate change.For every industry, we are a single stop company to deliver the chemical powder with standard quality at the right time. Even though we provide a lot of chemical powder, let us discuss the titanium dioxide manufacturer. Our titanium dioxide is highly durable, and it is in the form of white powder, which has its melting point is around 1830 ° C this dioxide is common to all type of the oxide of the metal. The titanium dioxide is not soluble in the water, and it found in the three mineral types, such as tetragonal rutile, rhombic brookite, and anatase.

Health Canada's Food Directorate recently completed a “state of the science” report on titanium dioxide (TiO2) as a food additive. Food-grade TiO2 is a white powder made up of small particles that has been permitted in Canada and internationally for many years as a food additive to whiten or brighten foods. Food-grade TiO2 has long been considered safe in Canada and in other countries when eaten as part of the diet.

In a 2021, Chinese researchers examined the impact of E171 on lipid digestion and vitamin D3 bioaccessibility in a simulated human gastrointestinal tract model. They examined Vitamin D’s bioaccessibility, or the amount it was released in the gastrointestinal tract, becoming available for absorption, and found it “significantly decreased from 80% to 74%” with the addition of E171. In the experiment, E171 decreased lipid digestion dose-dependently. Researchers wrote: “The findings of this study enhance our understanding toward the potential impact of E171 on the nutritional attributes of foods for human digestion health.” The study was published in the Journal of Agricultural and Food Chemistry,

blr-895 suppliers. This commitment to innovation ensures that their clients are always getting the best that the market has to offer.

The main treatment objects in coagulation stage are suspended organisms and colloidal impurities in water. The perfection of coagulation process has a great influence on subsequent treatment, such as sedimentation, filtration and chlorination, so it is a very important link in Water Treatment process. Polyaluminum chloride and polyferric sulfate are often used in most waterworks.

Titanium is a common metal element frequently found throughout nature. In our environment, titanium is naturally exposed to oxygen, forming titanium oxides that we find in many minerals, dusts, sands, and soils.