china warman horizontal slurry pump manufacturer

Latest articles

The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MoreThe same point of slurry pump and mud pump

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MoreSlurry pipe diameter.

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read Morehow-does-a-dredge-pump-work

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MorePumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MoreIncludes a large number of solids or particles.

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MoreSettling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MoreSlurry Pump

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MoreWill solids size pass through the pump?

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read MoreTypes of slurry pump installation.

china warman horizontal slurry pump manufacturer...

china warman horizontal slurry pump manufacturer 【china warman horizontal slurry pump manufacturer】

Read More

Popular articles

- What is 'slurry'?

- What is a dredging pump?

- WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

- Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

- What is 'slurry'?

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

Latest articles

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

-

Step 1

-

First, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

-

Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

-

A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

-

Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

Links

What is Redispersible Powder?

- One of the key characteristics of HPMC is its ability to form films and coatings. This property makes it an ideal ingredient in pharmaceuticals, where it is used as a coating for tablets and capsules to improve stability and appearance. HPMC is also used in the food industry as a thickener, emulsifier, and stabilizer in products such as sauces, beverages, and ice cream.

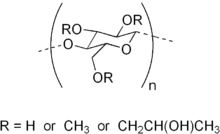

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose, a natural polymer found in plant cell walls. The derivation and modification of cellulose result in a product that combines the beneficial properties of cellulose with enhanced solubility and versatility. HEC is widely used across various industries due to its unique characteristics such as thickening, film-forming, and stabilizing abilities. This article explores the diverse applications of hydroxyethyl cellulose and highlights its importance in multiple fields.

- Self-Leveling Compounds HPMC is a key ingredient in self-leveling compounds, where its viscosity control is essential for achieving a smooth and even surface.

Overall, the unique properties of HPMC make it a versatile material that finds applications in various industries. From pharmaceuticals to construction, food to personal care, HPMC plays a crucial role in improving the quality and performance of products. As technology continues to advance, the demand for HPMC is expected to grow, driving further innovation and development in its uses and applications.

What Is HPMC Used For?

Redispersible polymer powders are produced through the spray-drying of polymer emulsions. The process transforms the emulsion into a fine powder that retains the aggregation of polymer particles. Upon mixing with water, these powders can rehydrate and reform the original emulsion, providing a range of functional properties such as improved adhesion, flexibility, and resistance to water.

Environmental concerns have also prompted research into the biodegradable properties of HPMC, promoting its use as a sustainable alternative to synthetic polymers. As industries increasingly pivot towards eco-friendly innovations, HPMC stands out due to its renewable origin and ability to reduce environmental impact.

Understanding HPMC Solubility Chart A Comprehensive Guide

1. Pharmaceuticals

4. Construction Industry

1. Construction Mortars One of the most prominent applications of REP is in the formulation of tile adhesives and construction mortars. The powder enhances adhesion, improves workability, and provides flexibility, making it an essential component in both interior and exterior applications.

2. Construction In building materials like cement, HPMC is employed as a thickener and water-retention agent. Its ability to dissolve in water enhances the workability of mixtures, improving the performance of mortar and plaster.

hpmc gel preparation.

Hydroxyethyl Cellulose Manufacturing Process

Conclusion

Hydroxypropyl methylcellulose (HPMC) is a widely used polymer in various industries, including pharmaceuticals, food, and construction. One of the critical thermal properties of HPMC is its glass transition temperature (Tg). Understanding Tg is essential for optimizing the performance of HPMC in its applications.

The degree of substitution of hydroxyl groups influences the solubility and viscosity of HPMC. Higher degrees of substitution typically result in higher solubility rates and the formation of thicker solutions. This versatility allows for customization in various applications depending on the required viscosity and solubility.

4. Local Chemical Suppliers

5

Hydroxyethyl cellulose is a remarkable polymer with numerous applications across various industries. Its unique properties make it an indispensable component for formulating products that require stability, texture, and quality. By understanding its benefits and applications, businesses can strategically incorporate HEC into their product lines, leading to enhanced user satisfaction and market competitiveness. As such, buying hydroxyethyl cellulose is not just a purchase; it is an investment in quality and performance.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose—that most abundant organic polymer found in nature. Thanks to its unique properties, HEC has found a wide range of applications across various industries, including pharmaceuticals, cosmetics, food, and construction. With an increasing demand for HEC in diverse applications, the market for hydroxyethyl cellulose for sale is growing steadily.

Understanding Hydroxyethyl Cellulose

In contrast, HPMC is frequently used in drug delivery systems, particularly in controlled-release formulations and film coatings. Its film-forming capabilities allow for the creation of sustained-release matrices that regulate the release of active pharmaceutical ingredients (APIs) over extended periods. This is especially beneficial for patients requiring consistent drug levels, minimizing spikes and troughs associated with immediate-release formulations.

hec vs hpmc

Where to Buy Cellulose Hydroxyethyl Cellulose A Comprehensive Guide

HPMC is a white, odorless powder that is soluble in cold water and forms a transparent gel when mixed. It is derived from natural cellulose through a chemical modification process, which enhances its water solubility and film-forming abilities. The compound is known for its thickening, emulsifying, and stabilizing properties, which play a significant role in various formulations.

Hydroxypropyl methyl cellulose is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration (FDA), making it a reliable ingredient in dietary supplements. Studies have shown that HPMC does not demonstrate toxicity or adverse effects when consumed within recommended limits. Its use is also supported by various food safety and health organizations worldwide.

In the pharmaceutical industry, HPMC is increasingly used as a binder and excipient in tablet formulations. The drug release characteristics can be finely tuned due to the polymer’s ability to form gels when in contact with fluids. This controlled-release capability is crucial for pharmaceuticals aiming to enhance bioavailability and reduce side effects. Moreover, HPMC is utilized in ophthalmic products, such as eye drops, where it serves as a thickening agent, providing lubricity and moisture to dry eyes. The biocompatibility of HPMC also makes it an ideal candidate for various medical applications, including hydrogels and wound dressings.

Pharmaceutical Applications

As the demand for innovative building solutions continues to grow, the HPMC market in China is expected to expand significantly. Various sectors, including residential, commercial, and industrial construction, are recognizing the value that HPMC brings to their projects. This trend is supported by ongoing research and development efforts aimed at optimizing HPMC formulations to enhance performance even further. As manufacturers invest in technology to improve production processes and explore new applications, the potential for HPMC in the construction industry appears limitless.

2. Food Industry HPMC serves as a thickening agent in food products, improving texture and stability. Its ability to dissolve in cold water while maintaining viscosity makes it ideal for various culinary applications, including sauces and dressings.

In the food industry, HPMC serves as a stabilizer, emulsifier, and thickening agent. Its functionality aids in maintaining texture and consistency in products such as sauces, dressings, and dairy items. Additionally, HPMC is popular in gluten-free products, where it helps to replicate the texture of traditional gluten-containing items, improving consumer acceptance.

4. pH and Ionic Strength The viscosity of HEC is also affected by the pH of the solution and the presence of salts or other ionic species. Changes in these conditions can alter the charge interactions within the polymer, subsequently affecting the viscosity.

Hydroxypropyl methylcellulose (HPMC) is a widely used polymer in various industries such as pharmaceuticals, construction, and food. It is an excellent film-former, thickener, and stabilizer due to its unique properties. One important aspect of HPMC is its grades, which determine its characteristics and applications in different sectors.

- Controlled-release Formulations HPMC is widely used in the development of sustained-release tablets, allowing for the gradual release of the active ingredient over an extended period. This is particularly beneficial for drugs that require consistent therapeutic levels in the bloodstream.

Food Industry Applications

Conclusion

Understanding Hydroxyethyl Cellulose Price Dynamics

It can be used as a thickening agent in toothpaste manufacturing.

In conclusion, the applications of redispersible polymer powders are extensive and varied, spanning multiple industries from construction to textiles. Their ability to improve the performance of products through enhanced adhesion, flexibility, and water resistance makes them a sought-after additive in many formulations. As research and development continue to advance, the potential uses of RPPs will likely expand further, contributing to the creation of innovative and high-performance materials. With a growing focus on sustainability and reducing environmental impact, the role of redispersible polymer powders in eco-friendly product development will become increasingly significant in the years to come.