china oem metal lined slurry pump manufacturer

Latest articles

>Slurry Pump

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read Moresets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreParticle size, shape and hardness (impact on wear and corrosion potential of pump components)

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreSlurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreStep 4

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read MoreApplications

china oem metal lined slurry pump manufacturer...

china oem metal lined slurry pump manufacturer 【china oem metal lined slurry pump manufacturer】

Read More

Popular articles

- TL FGD Pump

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

- As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- Lifetime use

- Consider the pump components

Latest articles

-

For example.

-

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

-

Rubber lined pumps offer many advantages

-

How to Choose a Dredging Pump or Slurry Pump

-

Slurry Pump Considerations

-

The Company Adopts Advanced Computer Aided Engineering Software

Links

Larger Working Surface

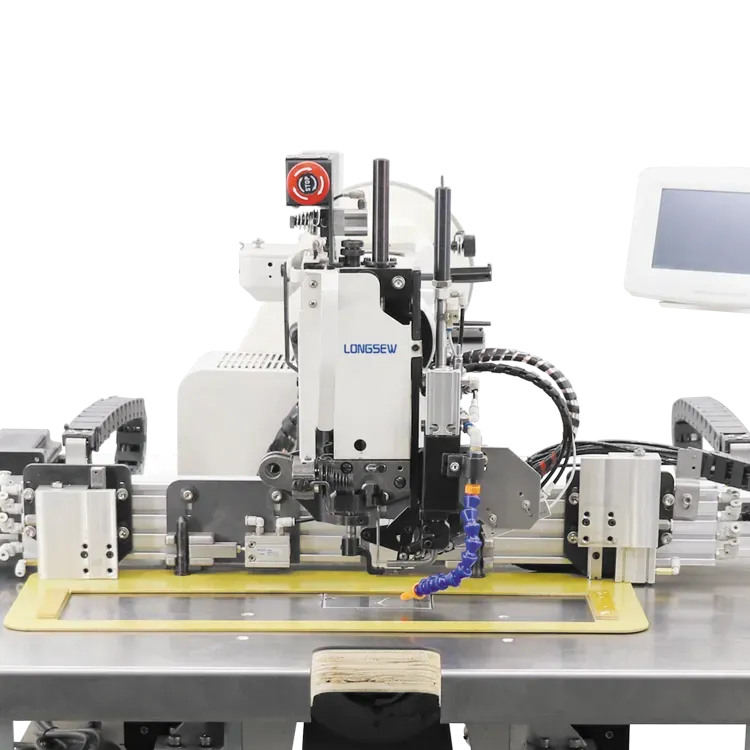

The Floating Foot Sewing Machine Revolutionizing the Craft of Sewing

At its core, an overlocker uses multiple threads—typically three to five—working in unison to create a secure stitch that finishes the edges of the fabric. The primary purpose of an overlocker is to prevent fraying, which is particularly important in fabrics that tend to unravel, such as knits and some woven materials. By enclosing the raw edges of the fabric, the overlocker effectively protects the integrity of the material and enhances the lifespan of the garment.

2. Training Skilled Labor Providing training for operators can significantly increase efficiency. Skilled workers can produce higher quality seams quicker, leading to a decrease in the overall machine rate.

One of the key advantages of the two needle stitch is its ability to accommodate stretch in fabrics

. When sewing knits or jerseys, for example, the two needle stitch allows for ample movement without compromising the integrity of the seam. The parallel lines create a “zigzag” effect between the stitches, which helps to maintain elasticity, making it ideal for activewear, swimwear, and casual clothing. Additionally, this technique is often used in decorative styles, enabling seamstresses to incorporate contrasting threads or colors, adding a visually appealing element to the garment.Conclusion

The Advancements and Applications of CNC Stitching Machines

The Essential Role of Jumbo Bag Sewing Machinery in Modern Manufacturing

- Flow Characteristics Different materials have different flow properties. For instance, granular materials might require wider spouts while powders could benefit from narrower openings to prevent clogging.

5. Versatility