china submersible pump companies factories

Latest articles

Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreSlurry pump considerations

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreMechanical Seals

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreOn the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreIf you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreIn dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreSubmersible Slurry Pump

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreSlurry Pump Impeller

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read MoreRepairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

china submersible pump companies factories...

china submersible pump companies factories 【china submersible pump companies factories】

Read More

Popular articles

- Slurry Pump

- In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

- >Slurry Pump

- 1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

- A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

Latest articles

-

Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

-

The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

-

Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

Slurry Pump

-

The main objective of all flush water programmes is to prevent contamination of the seals by pumped water.The flush water programme for boxes is therefore very similar to the flush water programme for mechanically sealed boxes. However there are still some obvious mechanical differences. The most notable difference is the addition of a seal (packing) between the inlet and outlet limits. This minimises the amount of flushing fluid consumed.

Links

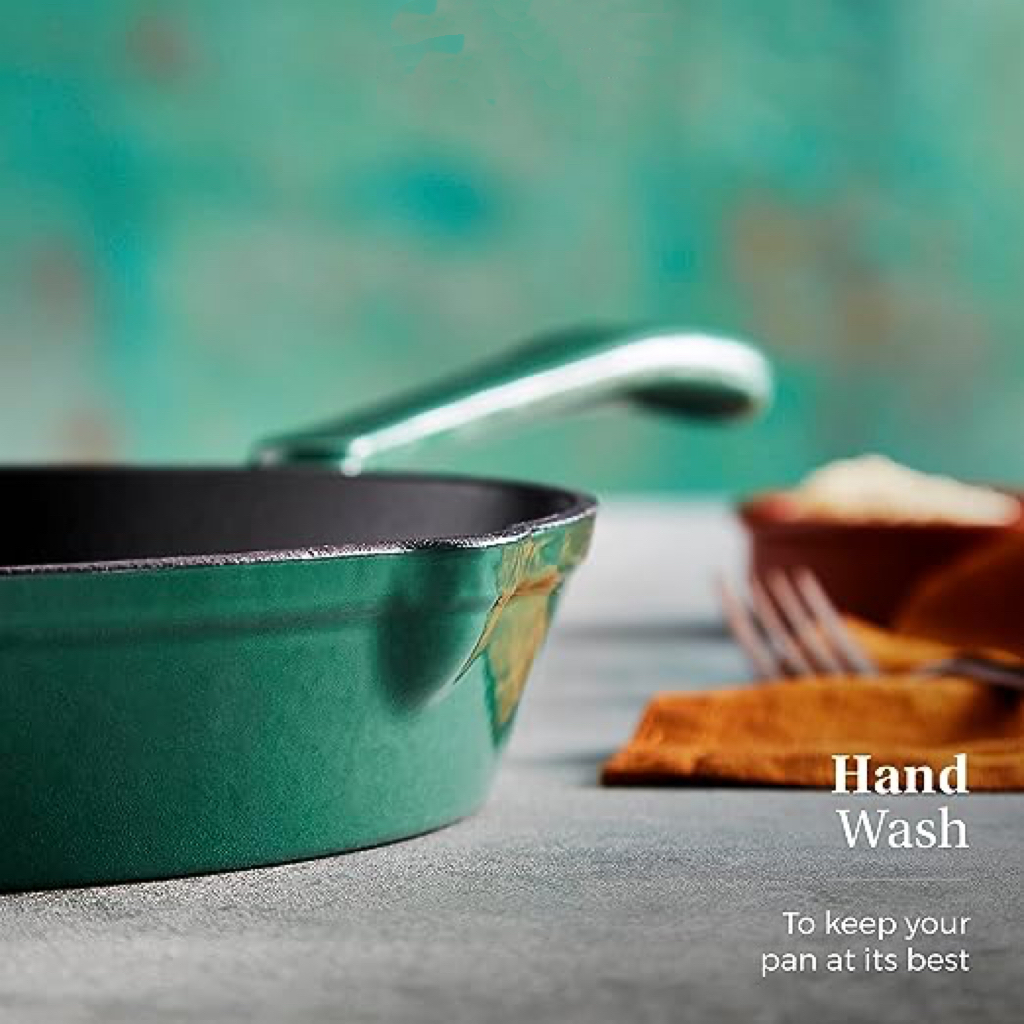

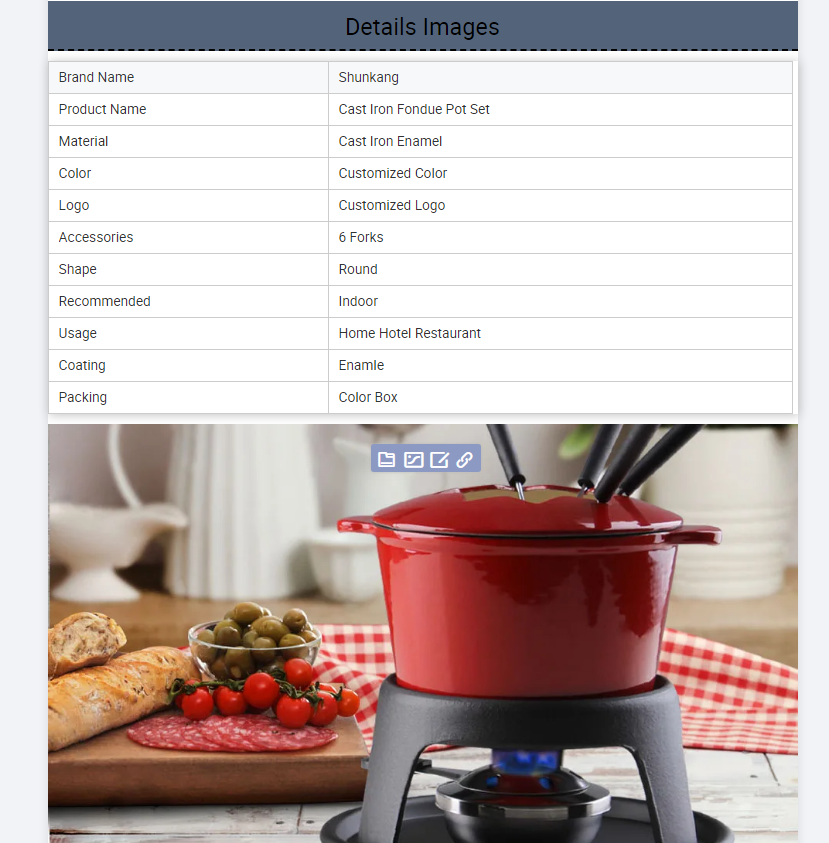

Cast Iron Flat Top Grill

They can also go from the stovetop to the oven without any issues, making them perfect for one-pot meals that require both simmering and baking They can also go from the stovetop to the oven without any issues, making them perfect for one-pot meals that require both simmering and baking

They can also go from the stovetop to the oven without any issues, making them perfect for one-pot meals that require both simmering and baking They can also go from the stovetop to the oven without any issues, making them perfect for one-pot meals that require both simmering and baking enamelware pot with lid.

enamelware pot with lid.

Restoring enamel cookware requires patience and care, but the right repair and maintenance can rejuvenate enamel cookware and extend its life. As a cast iron cookware manufacturer, we are committed to providing our customers with high-quality products and services.

The Differences Between Skillets and Pans

Considerations:

Dutch Oven Material

outdoor cast iron dutch oven. These pots can be used for a wide range of cooking methods, from roasting and baking to frying and sautéing. With a cast iron Dutch oven, you can cook just about anything outdoors, from hearty breakfast casseroles to savory one-pot dinners. And because they are so versatile, you can use them on a variety of heat sources, including campfires, grills, and even stovetops.

Durability and Versatility: Enamel cookware, including potjie pots, is known for its durability and versatility. It can be used for various cooking methods, including braising, stewing, and slow cooking, making it a versatile addition to any kitchen.

Carbon Steel Frying Pans

As well as its classic contemporary look, stainless steel cookware performs well due to its superior heat conduction. Highly durable and long-lasting, stainless steel pans do an excellent job at producing deliciously browned food and searing meat at high temperatures. While it’s true that they require somewhat more upkeep than other types of cookware to ensure they continue to perform optimally, but if you’re okay with giving your frypan a good scrub after cooking, then you can expect it to last you well over a decade.

Choose the frypan if you want something that is lightweight, easy to use daily, and offers versatility to cook delicate recipes. But if you're adventurous in the kitchen, enjoy cooking outdoors, have a larger budget and want cookware that lasts over a lifetime, choose the skillet.

Outdoor cast iron Dutch ovens are also a popular choice for camping and outdoor cooking. Outdoor cast iron Dutch ovens durable and heavy-duty Dutch ovens are designed to withstand the rigors of outdoor use, making them a reliable choice for outdoor cooking. Outdoor Cast Iron Dutch Oven cast-iron construction provides excellent heat retention and distribution, making them suitable for a variety of cooking methods, from baking to braising.

If you fill the French skillet with food, it will cook rather than fry it. However, the extra depth of these skillets can make them a bit more burdensome to store.