self priming slurry pump manufacturer

Latest articles

Typical Applications of slurry pump

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreHow does a dredge pump work?

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreSlurry pump power adjustment

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreOur firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreAny type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreDetermine the operating parameters of the pump.

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read Moreof a thick consistency, and.

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read MoreTypes of damage to slurry pumps

self priming slurry pump manufacturer...

self priming slurry pump manufacturer 【self priming slurry pump manufacturer】

Read More

Popular articles

- Using rubber as a wear lining material means

- What is a dredging pump?

- Consider the following.

- Dredge Pump

- Selecting And Operating A Slurry Pump

- Consider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

Latest articles

-

To reduce wear, reduce the pump discharge pressure to the lowest possible point.

-

Less downtime

-

For example.

-

2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

-

In harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

-

Less downtime

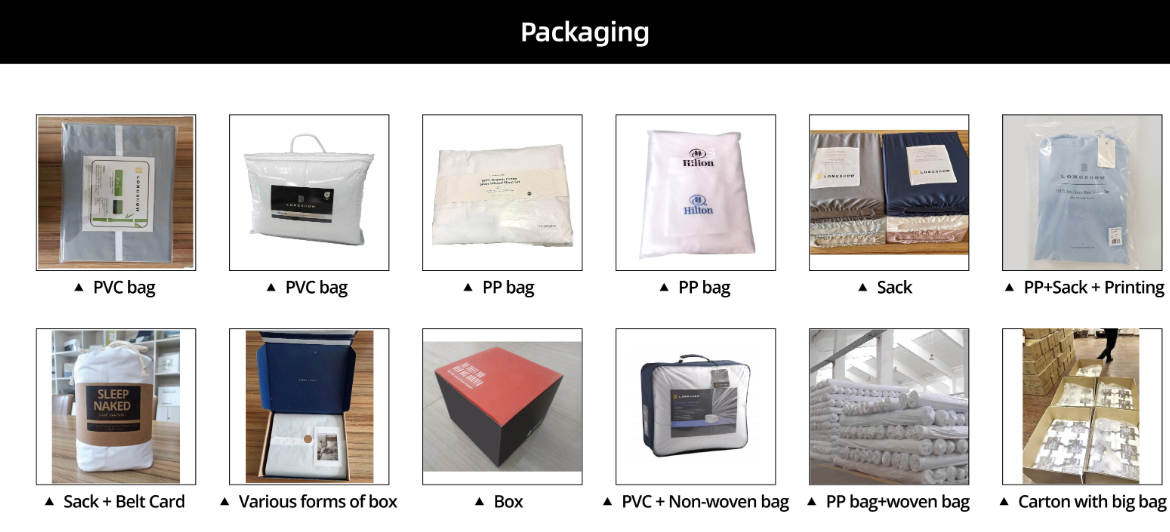

waffle robe mens. From classic solids to bold prints, there is something for everyone. You can choose a color that matches your bedroom decor or pick a pattern that reflects your personality. This allows you to express your style and make a statement with your choice of robe.

waffle robe mens. From classic solids to bold prints, there is something for everyone. You can choose a color that matches your bedroom decor or pick a pattern that reflects your personality. This allows you to express your style and make a statement with your choice of robe.

Bed Skirt, Dust Ruffle, or Valence

Before purchasing sheets, make sure you know the depth of your mattress. The depth of your mattress is the thickness and size of your mattress from top to bottom. This is very important to know when shopping for new sheets as it may alter the fit of standard sheets. Mattress depth can be categorized in the following ways:

Materials

When it comes to the best fabrics for bed sheets, cotton and linen are the undisputed frontrunners. The reason for their popularity is that both are natural fibers and possess qualities such as high absorbency and breathability that make them the perfect choice for bedding. But determining which one is best for you is not as easy as it may seem. Picking the right set of bedsheets is a personal decision that has a lot to do with the kind of sleeper you are and the aesthetics you’d like your bedroom to evoke. The textiles manufactured from cotton and linen deliver two distinct experiences both in terms of style and feel.

COTTON SHEETS Cotton sheets are breathable, cool, soft and wicks moisture away from your skin. They also come in both natural and synthetic options depending on your preferences. The difference between these cottons is that the synthetic variety is more durable and inexpensive, while the natural option provides a more comfortable feel. Regardless of which type of cotton you choose, they are both durable, soft, and easy to maintain.

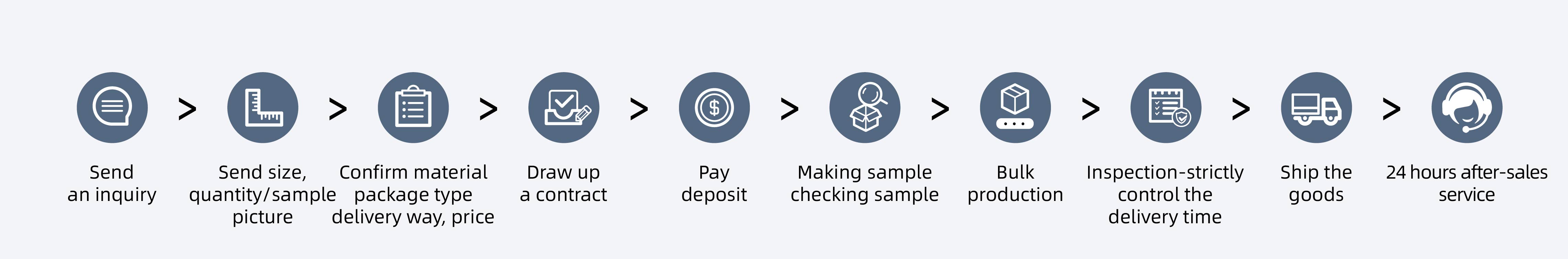

They understand the importance of prompt delivery, quality assurance, and after-sales support, thus building long-lasting relationships with their clients They understand the importance of prompt delivery, quality assurance, and after-sales support, thus building long-lasting relationships with their clients

They understand the importance of prompt delivery, quality assurance, and after-sales support, thus building long-lasting relationships with their clients They understand the importance of prompt delivery, quality assurance, and after-sales support, thus building long-lasting relationships with their clients bedsheet wholesalers. Many wholesalers also provide customization services, allowing retailers to order specific sizes, colors, or designs to meet local.

bedsheet wholesalers. Many wholesalers also provide customization services, allowing retailers to order specific sizes, colors, or designs to meet local.