stainless steel sewage pump manufacturers

Latest articles

Slurry Pump

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreHow to Succeed in Slurry Pumping?

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreAs described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreRubber Lined Slurry Pump

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreFor certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreLifetime use

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read Morehow-does-a-dredge-pump-work

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreSlurry Pump

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read MoreSlurry Pump

stainless steel sewage pump manufacturers...

stainless steel sewage pump manufacturers 【stainless steel sewage pump manufacturers】

Read More

Popular articles

- A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

- Slurry Pump

- Reduced inventory

- I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

- Critical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

- Metal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

Latest articles

-

Mill sump

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

In a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

-

The concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

-

Two types of slurry are found in these industries.

-

How much solids damage can the customer tolerate?

Links

- When looking for a jack hammer for sale, consider the following factors

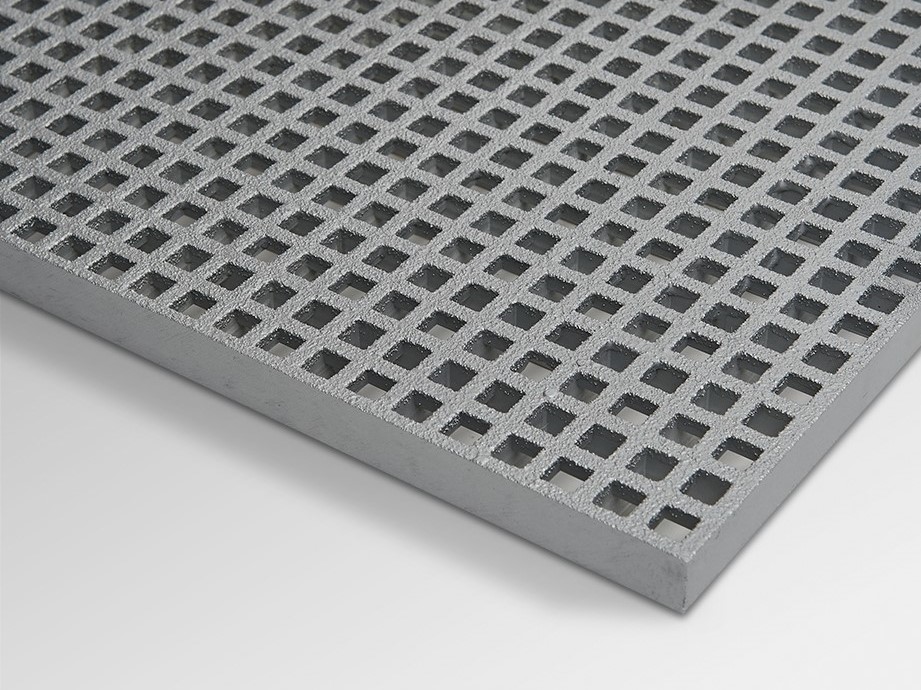

2.Conductive fiberglass grating

Fibergalss grating itself is an insulator, non conductive, non thermal conductivity, but in some specific places, it also has a conductive requirements. The detailed operation method is to eliminate the damage of static charge inoculation in the rock layer with a thickness of about 3~5mm. The conductive grating also has same characteristics with traditional glass steel grille ,such as corrosion resistance, flame retardant,anti strike, skid resistance, light weight and practical in refinery and armaments manufacturing factory, high-tech industry, computer room, chemical plants, dry areas and underground mining operations.- Configuring FRP scrubber involves several steps, which are outlined below

- Despite their robust nature, hex shank drill bits require proper maintenance to prolong their lifespan. After usage, they should be cleaned of debris and stored in a dry place to prevent rusting. Regular sharpening is also essential to maintain optimal performance.

- Despite its smaller stature, the lightweight jack hammer maintains a formidable impact force. With a typical impact energy ranging from 20 to 40 joules, it can effortlessly tackle even the most robust materials. Paired with interchangeable bits, it adapts to various job requirements, making it a versatile addition to any toolbox.

pultruded fiberglass grating. It can be cut to size on site without the need for special tools, and its non-corrosive properties mean it requires minimal maintenance over its long lifespan.

pultruded fiberglass grating. It can be cut to size on site without the need for special tools, and its non-corrosive properties mean it requires minimal maintenance over its long lifespan.If you work in construction in any way, you will most likely need to use FRP grating at some point.

This isophthalic polyester resin formulation is designed for industrial and chemical processing applications where corrosion resistance is important. Color: green or dark gray. Flame Spread: ASTM rating of 20 or less. IFR is also available in a UL Classified resin formulation.

Their size, shape, and thickness can be tailored according to specific application needs, allowing for a tailored solution Their size, shape, and thickness can be tailored according to specific application needs, allowing for a tailored solution

Their size, shape, and thickness can be tailored according to specific application needs, allowing for a tailored solution Their size, shape, and thickness can be tailored according to specific application needs, allowing for a tailored solution frp rectangular tank. They can also be manufactured with different lining and coating materials to enhance specific properties like temperature resistance or UV stability.

frp rectangular tank. They can also be manufactured with different lining and coating materials to enhance specific properties like temperature resistance or UV stability.

IMPLEMENTASI PENGGUNAAN HI-GRID FRP MOLDED GRATING