warman centrifugal slurry pump factory

Latest articles

Mill sump

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreKeep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreFor example.

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreAier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read More>Slurry Pump

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreTL FGD Pump

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreHorizontal pumps are the most commonly used type of slurry pump and therefore have the advantage of being easy to install or maintain, a wide range of flow parameters to choose from and a wide range of design materials to choose from. One of the advantages of vertical pumps, however, is the relatively small amount of floor space required for installation.

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreChoosing Dry Slurry Pumps Versus Submersible Slurry Pumps

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

warman centrifugal slurry pump factory...

warman centrifugal slurry pump factory 【warman centrifugal slurry pump factory】

Read More

Popular articles

- Heavy-Duty Slurry Pump

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- If you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

- Applications

- Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

- Ideal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

Latest articles

-

The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

How to Succeed in Slurry Pumping?

-

The terms slurry pump and dredge pump can be used interchangeably.

Links

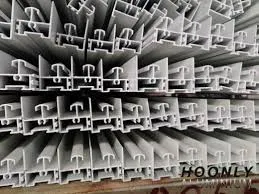

- The primary purpose of mosquito net aluminium profile is to create a rigid framework for the mosquito net. This framework not only provides stability but also ensures that the net maintains its shape and size, allowing it to cover a larger area. By using aluminium profiles, manufacturers can create nets with larger openings, making them more accessible and user-friendly.

Aesthetic Appeal

Thus, aluminum profiles for windows and doors with anodized finish are resistant to corrosion since the layer prevents it from occurring.

When choosing a steel box lock, it is important to consider your specific needs and the level of security required for your valuables. Whether you opt for a traditional key lock, a convenient combination lock, or a high-tech digital lock, investing in a quality lock is essential for safeguarding your possessions. By taking the time to choose the right lock for your steel box, you can rest easy knowing that your valuables are secure and protected.

Most hardware stores or online retailers will have a range of options available Most hardware stores or online retailers will have a range of options available

Most hardware stores or online retailers will have a range of options available Most hardware stores or online retailers will have a range of options available changing sliding door rollers.

changing sliding door rollers.4. Energy Efficiency Modern slimline aluminium profiles can be designed with thermal breaks, which significantly improve their insulation properties. This means that buildings can achieve higher energy efficiency, leading to lower heating and cooling costs. In an era where sustainability is paramount, this feature makes slimline profiles an excellent choice for environmentally conscious construction.

Despite their many advantages, aluminum window extrusion profiles do have some drawbacks. One of the main concerns with aluminum windows is their poor thermal performance. Aluminum is a highly conductive material, meaning that it can easily transfer heat and cold into and out of the home. This can lead to increased energy costs as the home's heating and cooling systems work harder to maintain a comfortable temperature.

Excellent weather resistance

heavy duty door rollers.

In the ever-evolving field of modern architecture, aluminum profiles, as the conrnerstone of aluminum door and window design, combine durability, versatility, and many other advantages, and designers are able to design a variety of specific aluminum doors and windows to meet different scenarios based on the characteristics of aluminum profiles.

Aluminum profiles are the best choice in construction, automobile, industrial and other fields. In this article, we will take an in-depth look at its types, advantages and considerations when choosing them.

Direct Extrusion

Versatility of Use

Style

In most instances, the pricing is usually based on the company’s reputation in providing quality aluminum profiles

An organized outdoor space enhances the overall aesthetics and functionality of your home. With a lockable metal storage box, you can keep your outdoor area tidy and free from clutter. Instead of leaving items strewn about, you can stow them away securely, making it easier to enjoy your outdoor living space. This not only makes your environment more inviting for guests but also helps you find what you need quickly and easily.

Steel door pull handles require minimal maintenance compared to other materials. A simple wipe down with a damp cloth is usually sufficient to keep them looking new. Unlike wood, which may need periodic refinishing, or plastic, which can discolor over time, steel handles can withstand the test of time with little upkeep. Their resistance to rust and tarnishing, particularly when finished properly, ensures longevity and an appealing appearance.