In conclusion, the manufacturing process of redispersible polymer powder involves careful selection of raw materials, emulsion polymerization, spray drying, milling, and rigorous quality control. Each step plays a significant role in determining the quality and characteristics of the final product, which is crucial for its performance across various applications in construction and beyond.

When considering purchasing HEC, several benefits make it an attractive choice for manufacturers and DIY enthusiasts

Pharmaceutical Applications

Chemical Properties and CAS Number

HPMC is also found in the cosmetic sector, where it acts as a thickener, emulsifier, and film-forming agent in a range of products, including lotions, creams, and shampoos. Its ability to provide a smooth texture and stability makes it a favorable choice in formulating cosmetic products. Additionally, HPMC contributes to the moisturizing properties in skincare products, making it an essential component for modern beauty formulations.

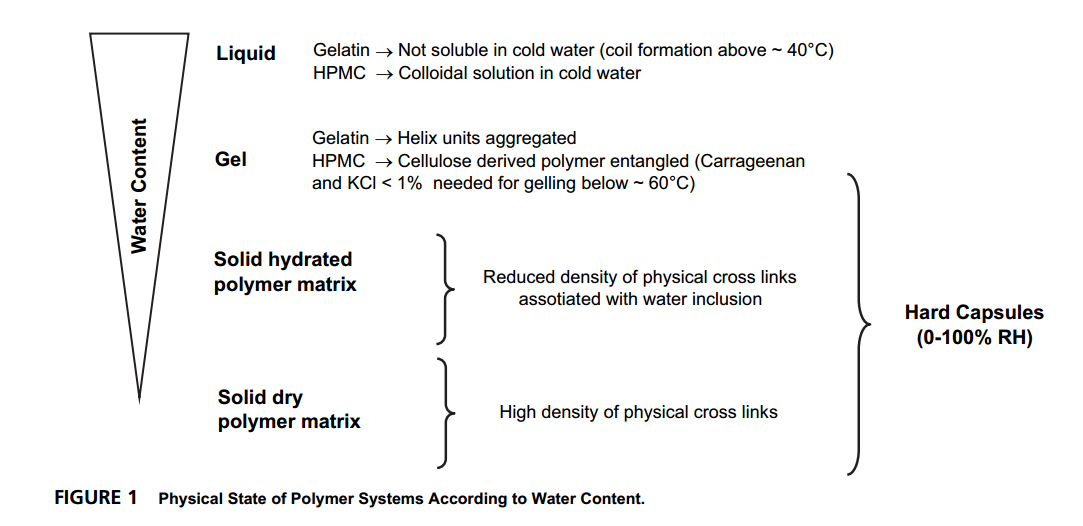

Temperature itself is another fundamental factor. HPMC solutions behave differently at varying temperatures, causing shifts in gelation temperature. As the temperature increases, the solubility of HPMC in water changes, which can either promote or inhibit gel formation. Furthermore, the presence of salts and other additives can modify the gelation temperature by affecting the ionic strength of the solution, leading to alterations in the intermolecular interactions of HPMC chains.

hpmc gelation temperature

Properties of Hydroxypropyl Methylcellulose Powder

Hydroxyethylcellulose (HEC) is a versatile and widely used polymer that serves a variety of purposes across different industries. It is a non-ionic, water-soluble polymer that is derived from cellulose, a natural polymer found in plants. HEC is a key ingredient in many consumer products, pharmaceuticals, cosmetics, and industrial applications due to its unique properties.

HPMC is also known for its ability to increase the consistency of mortar, making it easier to apply and shape. This is particularly useful in situations where precise detailing is required, such as in the installation of tiles or decorative elements. The improved workability provided by HPMC also helps to reduce wastage and improve overall productivity on construction sites.

hpmc for mortar

3. Food Industry In the food sector, HPMC is employed as a food additive due to its thickening, emulsifying, and stabilizing properties. It is used in various products, including sauces, dressings, and dairy products, improving texture and mouthfeel.

The Versatility and Benefits of Hydroxyethylcellulose

The pharmaceutical industry heavily relies on HPMC for its ability to produce controlled-release formulations. It is commonly utilized in tablet coatings and as a binder in solid dosage forms, ensuring that medications are released in a sustained manner, enhancing bioavailability and patient compliance.

Moreover, the versatility of redispersible polymer powders allows them to be used in a wide range of applications, such as tile adhesives, exterior insulation and finish systems (EIFS), self-leveling compounds, and repair mortars

. They can be tailored to meet specific performance criteria, which makes them an indispensable tool for formulators seeking to optimize their products.