china sewage drainage pump factory

Latest articles

of a thick consistency, and.

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read More- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreLow slurry flow rates

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreAny type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreA slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreA target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read MoreFloor drainage

china sewage drainage pump factory...

china sewage drainage pump factory 【china sewage drainage pump factory】

Read More

Popular articles

- Slurry Pump

- There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

- Slurry Pump VS Mud Pump

- Step 2

- target=_blank>Slurry Pump

- WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

Latest articles

-

It is important that the pump you choose has components that will not wear out from abrasive slurries.

-

Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

-

What is a dredging pump?

-

Typically, slurries are.

-

how-does-a-dredge-pump-work

-

As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

Links

- no evidence of cancer or other adverse effects in mice and rats exposed to high concentrations of food-grade TiO2 (long-term or lifetime study)

- Iron Oxide Pigment Suppliers A Key Player in the Global Colorant Industry

- Transparent TiO2 is produced through a proprietary process that involves the controlled hydrolysis and oxidation of titanium tetrachloride. The resulting particles are micronized to achieve the desired particle size and distribution, which is critical for achieving optimal transparency and color performance.

Ashes % Lithopone 30% has a lower coverage power than titanium dioxide. For this reason, Lithopone 30% can only partially substitute titanium dioxide, between 5 and 40%.

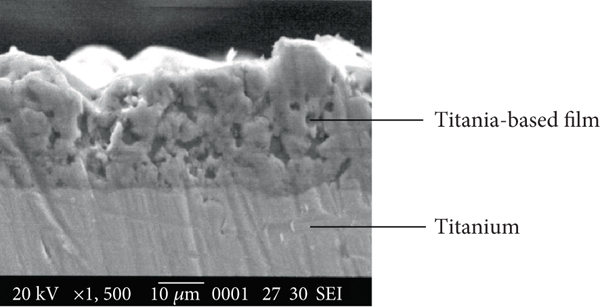

The biological activity, biocompatibility, and corrosion resistance of implants depend primarily on titanium dioxide (TiO2) film on biomedical titanium alloy (Ti6Al4V). This research is aimed at getting an ideal temperature range for forming a dense titanium dioxide (TiO2) film during titanium alloy cutting. This article is based on Gibbs free energy, entropy changes, and oxygen partial pressure equations to perform thermodynamic calculations on the oxidation reaction of titanium alloys, studies the oxidation reaction history of titanium alloys, and analyzes the formation conditions of titanium dioxide. The heat oxidation experiment was carried out. The chemical composition was analyzed with an energy dispersive spectrometer (EDS). The results revealed that titanium dioxide (TiO2) is the main reaction product on the surface below 900°C. Excellent porous oxidation films can be obtained between 670°C and 750°C, which is helpful to improve the bioactivity and osseointegration of implants.

- In addition to protecting structures, chemical building coatings also play a crucial role in enhancing the aesthetics of buildings. These coatings come in a wide range of colors and finishes, allowing architects and designers to create visually appealing facades that complement the surrounding environment. Whether it's a sleek, modern look or a classic, traditional finish, there is a chemical coating that can help achieve the desired aesthetic.

The California plaintiff is apparently not the only one concerned about titanium dioxide. The European Union recently banned its use citing concerns about serious health consequences.

Durabo White, 24.5 per cent zinc sulphide, 51 per cent barium sulphate, 18 per cent white clay, 5.5 per cent infusorial earth.

A.B. 418, authored by Assemblymember Jesse Gabriel (D-San Fernando Valley), will soon receive its final votes in the state legislature. If the bill is signed into law, the Golden State would be the first in the nation to ban these toxic chemicals from bread, salad dressings, frozen pizzas and other popular food items.

Très apprécié dans le travail des Icônes pour éclaircir, mais également pour les vernis, émaux, peintures, plastique et papier. A l'inverse, ne pas utiliser ce produit dans les applications cosmétiques, comme additif alimentaire ou comme additif médicamenteux.

Europe

CAS NO. :

Even though it is one of the most-produced chemicals, the real and potential benefits of titanium dioxide are not without controversies. Dust inhalation may cause breathing problems. Titanium dioxide has been classified by the International Agency for Research on Cancer as an Group 2B carcinogen, a “possible carcinogen to humans,” based on studies of rats that inhaled the substance.

Although barium sulfate is almost completely inert, zinc sulfide degrades upon exposure to UV light, leading to darkening of the pigment. The severity of this UV reaction is dependent on a combination of two factors; how much zinc sulfide makes up the pigments formulation, and its total accumulated UV exposure. Depending on these factors the pigment itself can vary in shade over time, ranging from pure white all the way to grey or even black. To suppress this effect, a dopant may be used, such as a small amount of cobalt salts, which would be added to the formulation. This process creates cobalt-doped zinc sulfide. The cobalt salts help to stabilize zinc sulfide so it will not have as severe a reaction to UV exposure.

This food chemical has been used in food for more than half a century, but recent studies show it may be harmful.

For research published in 2022 study in the journal Food and Chemical Toxicology, scientists examined “the genotoxicity and the intracellular reactive oxygen species induction by physiologically relevant concentrations of three different TiO2 nanomaterials in Caco-2 and HT29-MTX-E12 intestinal cells, while considering the potential influence of the digestion process in the NMs’ physiochemical characteristics.” They found a “DNA-damaging effect dependent on the nanomaterial,” along with the micronucleus assay suggesting “effects on chromosomal integrity, an indicator of cancer risk, in the HT29-MTX-E12 cells, for all the tested TiO2 nanomaterials.” Researchers concluded that the results showcase “evidence of concern” regarding titanium dioxide used as a food additive.

Stability and darkening

Packaging containing this additive has been shown to decrease ethylene production in fruit, thus delaying the ripening process and prolonging shelf life (4Trusted Source).

Research supports that applying titanium dioxide to the skin in the form of sunscreens, makeup, and other topical products does not pose any health risks.