slurry pump impeller wear factory

Latest articles

-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreDepending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreFor more information about this new and improved pump, please contact us.

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreA >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreWZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreTraditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreSelecting a dredge pump

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read MoreDry Installation

slurry pump impeller wear factory...

slurry pump impeller wear factory 【slurry pump impeller wear factory】

Read More

Popular articles

- Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

- With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

- testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

- What is 'slurry'?

- Slurry Pump Impeller Size

- Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

Latest articles

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

-

Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

-

Slurry Pump

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

-

As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

Links

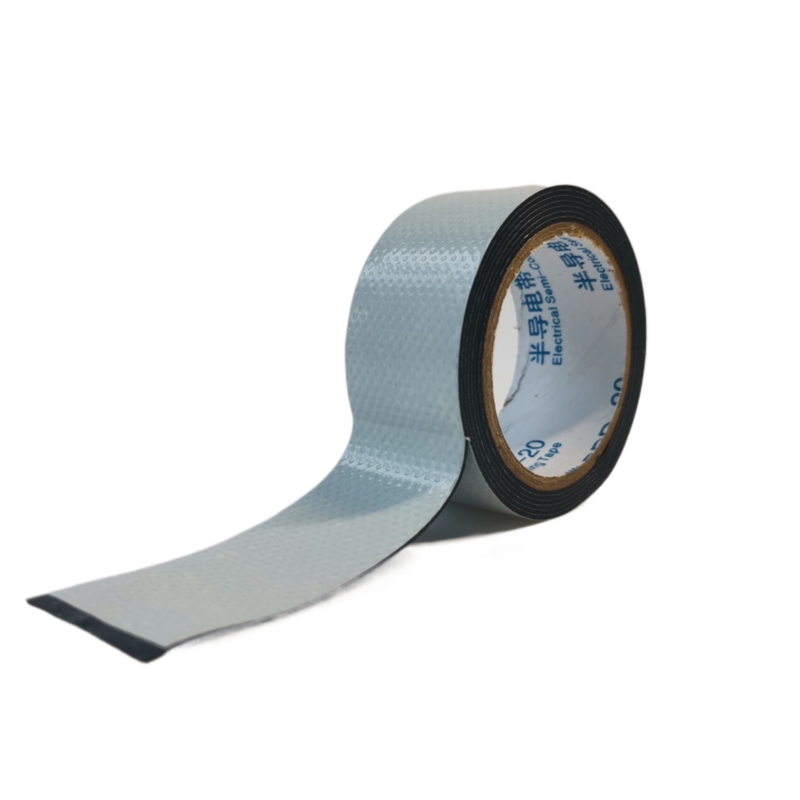

If you have any more questions about our silicone tapes, or any other tape products, please get in touch and contact us via live chat, email or telephone.

The Different Types of Electrical Insulation Tape and Their Uses

The Versatility and Importance of 50mm Black Insulation Tape

Types of Heat Tape

self bonding electrical tape. It provides a layer of protection against electrical shock and short circuits, making it a critical component in any electrical work.

Water and Solvent Based Acrylics

Fire-resistant electrical tape is typically made from durable materials such as PVC (polyvinyl chloride), which can endure higher temperatures than standard tapes. These tapes are coated with flame-retardant compounds that significantly reduce the risk of ignition when exposed to heat or flames. Some products may also have a backing made of fiberglass or other inherently flame-resistant materials, adding an extra layer of protection.

pvc floor masking tape. After the paint has dried, the tape can be pulled up slowly at a 45-degree angle, taking care not to jerk it too quickly to avoid damaging the newly painted surface. If removed correctly, the tape will come off without leaving residue, saving time and effort in cleanup.

pvc floor masking tape. After the paint has dried, the tape can be pulled up slowly at a 45-degree angle, taking care not to jerk it too quickly to avoid damaging the newly painted surface. If removed correctly, the tape will come off without leaving residue, saving time and effort in cleanup.Our Self-Fusing Tape Range.

Some common applications of butyl rubber tape include using it for window and door installations, sealing gutters, fixing automotive leaks, and even in HVAC systems to create airtight seals. In the construction industry, contractors often use it for flashing around windows and roofs to prevent leaks during construction and in finished structures.

waterproof door seal strip. A tight seal around the door prevents sound from traveling through the gaps, creating a quieter and more peaceful environment. This can be particularly beneficial for homes or buildings located in noisy neighborhoods or areas with high traffic.