china industrial submersible sump pump factory

Latest articles

The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreAs a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreThe selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreThe frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreSlurry Pump

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreStep 4

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreDredge Pump Features

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read MoreDetermine the operating parameters of the pump.

china industrial submersible sump pump factory...

china industrial submersible sump pump factory 【china industrial submersible sump pump factory】

Read More

Popular articles

- Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

- Low slurry flow rates

- Slurry Pump

- Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

- Choosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

- Customised pumps

Latest articles

-

To find out more about Aier slurry Pumps, please >contact us.

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

-

The selection of a dredge or , slurry pump, can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

-

The design of the slurry pump is critical to ensure that the abrasive and often corrosive aspects of the slurry do not damage the impeller. In addition, slurries and sludges may contain large amounts of unforeseen solids, which will inevitably clog many types of pumps. Since most centrifugal pump impellers have very tight tolerances on the worm gear, the abrasive (and sometimes corrosive) nature of the slurry will quickly wear down the worm gear and destroy the tolerances. In turn, this causes the pump to lose suction. This can lead to extensive downtime of the slurry pump, as well as expensive maintenance and spare parts.

-

Slurry Pump VS Mud Pump

-

The Company Adopts Advanced Computer Aided Engineering Software

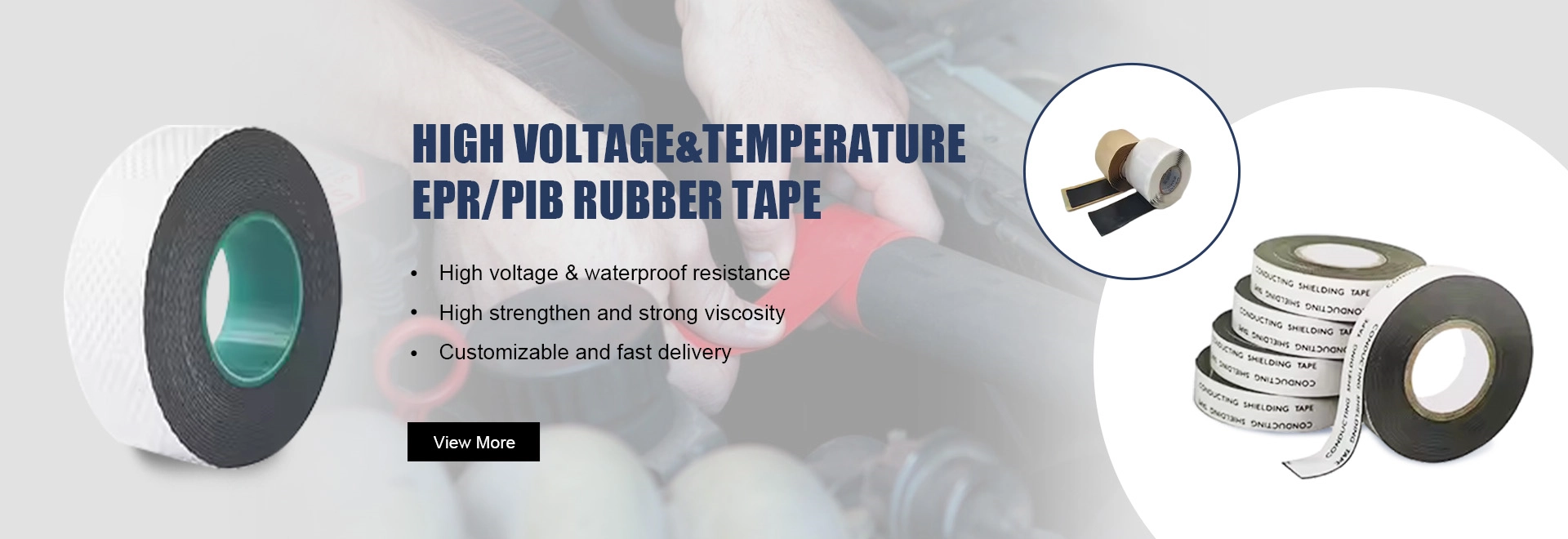

7. Easy to use: a layer of Self Fusing tape can play a good insulation role and reduce labor and cost.

In plumbing repairs, amalgamating rubber tape is often used to fix leaks and reinforce pipe joints

. The tape can be applied to the damaged area and wrapped tightly to create a waterproof seal. Its flexibility and strength make it an ideal solution for emergency repairs or as a temporary fix until a permanent solution can be implemented.amalgamating rubber tape

Polyethylene Rubber Tape has several important characteristics:

The primary difference between electrical and duct tape is their composition and material. Electrical tape is made from plastic vinyl or PVC, giving it a smooth and stretchy texture. Electrical tape is heat resistant and designed specifically for safely insulating electrical wires and materials that conduct electricity.

One of the key benefits of self-adhesive electrical tape is its ease of use. Simply peel off the backing and apply the tape to the desired area. The strong adhesive will ensure that the tape stays in place, providing a secure and reliable seal.

If you’re working with live wires, for example, it’s always best to err on the side of caution and use heat-resistant tape instead.

Prepare the Surface: Ensure the surface you're applying the tape to is clean and dry. This will help the tape adhere properly.

cloth electrical tape. Its strong adhesive and durable nature make it ideal for fixing torn items, holding items together temporarily, or even for DIY projects. Its waterproofing capabilities further extend its usability to plumbing repairs or sealing packages.

cloth electrical tape. Its strong adhesive and durable nature make it ideal for fixing torn items, holding items together temporarily, or even for DIY projects. Its waterproofing capabilities further extend its usability to plumbing repairs or sealing packages.Conclusion

Compliance with Fire Safety Regulations

fire seal tape