china vertical submersible slurry pump suppliers

Latest articles

First, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreI hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreWhat is Heavy Duty Slurry Pump?

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreDesire for higher efficiency than centrifugal pumps

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreTypes of slurry pumps

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreThe terms slurry pump and dredge pump can be used interchangeably.

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreOur firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read MoreEspecially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

china vertical submersible slurry pump suppliers...

china vertical submersible slurry pump suppliers 【china vertical submersible slurry pump suppliers】

Read More

Popular articles

Latest articles

-

For pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

-

Slurry Pump

-

If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

-

If the exact in-pump viscosity of the product is unknown, CSI can help

-

WL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

-

Auxiliary equipment

Links

- Regular maintenance and inspection of rock drill tools are essential to ensure their optimal performance and longevity. Proper lubrication, cleaning, and replacement of worn-out parts are necessary to prevent breakdowns and delays in tunnel drilling operations. Routine maintenance also helps to identify any potential issues or defects in the rock drill tools before they cause any problems.

- 4. Use Corrosion-Resistant Accessories Install corrosion-resistant accessories such as elbows, tees, and couplers made from materials like stainless steel or aluminum to reduce the risk of corrosion at joints and connections.

- 4. Environmental Friendliness MF rock drill rod is made from recycled materials, making it an environmentally friendly alternative to traditional drill rods. This helps businesses reduce their carbon footprint and meet sustainability goals.

- When selecting a drill bit extension rod, it's crucial to consider factors such as length, material, and compatibility

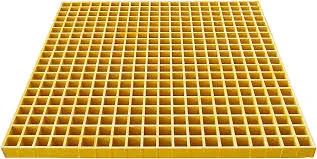

- Fiberglass, also known as glass fiber reinforced plastic (GFRP), is a composite material made by combining glass fibers with a polymer matrix. This combination imparts exceptional strength and stiffness to the material, making it an ideal choice for storage tanks that need to withstand harsh environmental conditions.

- In addition to drilling, a 34mm bit can also be utilized for other purposes, such as counterboring or boring holes for large bolts or pipes. With its wide diameter, it can create ample space for a secure fitment, ensuring structural integrity.

- In addition to the materials used in their construction, vessels and tanks must also be designed with features that ensure the safety and efficiency of their operation

Always ensure that the attachments are made of durable materials to withstand the rigors of work Always ensure that the attachments are made of durable materials to withstand the rigors of work

Always ensure that the attachments are made of durable materials to withstand the rigors of work Always ensure that the attachments are made of durable materials to withstand the rigors of work It can be used both handheld for precision work or mounted on a stand for more controlled, larger-scale operations It can be used both handheld for precision work or mounted on a stand for more controlled, larger-scale operations

It can be used both handheld for precision work or mounted on a stand for more controlled, larger-scale operations It can be used both handheld for precision work or mounted on a stand for more controlled, larger-scale operations

They can be fabricated in various shapes, sizes, and thicknesses to meet specific application requirements They can be fabricated in various shapes, sizes, and thicknesses to meet specific application requirements

They can be fabricated in various shapes, sizes, and thicknesses to meet specific application requirements They can be fabricated in various shapes, sizes, and thicknesses to meet specific application requirements