china casting slurry pump part factory

Latest articles

Particle size, shape and hardness (impact on wear and corrosion potential of pump components)

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read More>Dredge Pump

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read MoreIn AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read MoreThe length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read MoreAs wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read MoreSlurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read MoreWhat is the pump constructed of?

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

china casting slurry pump part factory...

china casting slurry pump part factory 【china casting slurry pump part factory】

Read More

Popular articles

- Non-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

- When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

- Slurry Pump

- If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

- The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

- Working principle

Latest articles

-

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

-

In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

The design of the slurry pump is critical to ensure that the abrasive and often corrosive aspects of the slurry do not damage the impeller. In addition, slurries and sludges may contain large amounts of unforeseen solids, which will inevitably clog many types of pumps. Since most centrifugal pump impellers have very tight tolerances on the worm gear, the abrasive (and sometimes corrosive) nature of the slurry will quickly wear down the worm gear and destroy the tolerances. In turn, this causes the pump to lose suction. This can lead to extensive downtime of the slurry pump, as well as expensive maintenance and spare parts.

-

Determine the nature of the material to be pumped

-

Slurry Pump Selection

Links

- In the realm of water storage systems, fiberglass water tanks have emerged as a prominent choice due to their numerous advantages over traditional materials. These tanks, made primarily from a composite of glass fibers and a polymer resin matrix, are designed to provide efficient, durable, and eco-friendly water storage solutions.

The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs

The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs The material can be molded into complex shapes, allowing for more aerodynamic and visually striking designs frp car. This has opened up new avenues for automotive designers, pushing the envelope of aesthetic possibilities. From sleek curves to sharp edges, the versatility of FRP allows for a level of customization that was once unimaginable.

frp car. This has opened up new avenues for automotive designers, pushing the envelope of aesthetic possibilities. From sleek curves to sharp edges, the versatility of FRP allows for a level of customization that was once unimaginable. This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported

This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported This can lead to a form of groupthink where fans defend their version of the story against alternative interpretations, even if those interpretations are more logical or well-supported grp fan.

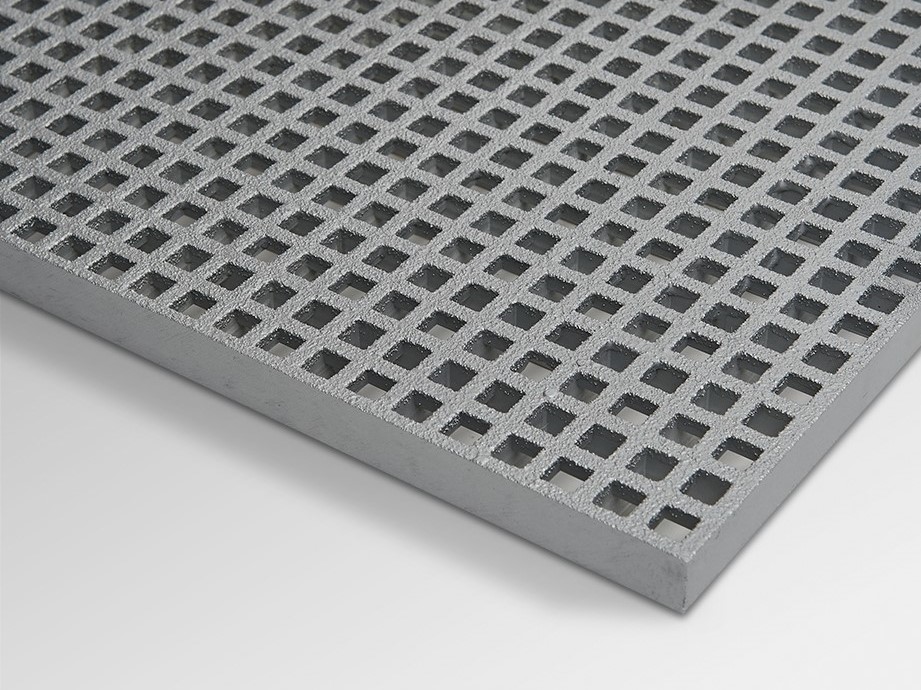

grp fan.It is also ideal for chemically hazardous projects like chemical plants. FRP grating is non-corrosive and will not become damaged by exposure to chemicals.

With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites

With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites With the option to add or remove extension rods based on the drilling requirements, they offer versatility in various terrains and job sites rock drill extension rod. They can adapt to different drilling angles and configurations, making them adaptable to diverse geological conditions.

rock drill extension rod. They can adapt to different drilling angles and configurations, making them adaptable to diverse geological conditions.Selain ukuran standar, kami juga dapat memproduksi grating ukuran custom. di indonesia produk grating mempunya variasi yang paling banyak mesh 38×38, mesh 50×50, mesh rectanguler 100 x 25, mesh rectanguler 152 x 38, mini mesh 20×20, micro mesh 13×13 dan juga dengan tinggi yang bervariatif dari H25, H30, H38 dan 50. Untuk Permukaan yang tersedia adalah concave, anti skid, chequer plate dan flat.