slurry pump exchangable with warman pumps

Latest articles

Slurry Pump Selection

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreThe discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreMud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreSump drainage or washdown

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreLight-duty Slurry Pump

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

slurry pump exchangable with warman pumps...

slurry pump exchangable with warman pumps 【slurry pump exchangable with warman pumps】

Read More

Popular articles

- Step 3

- A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

- Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

- Step 3

- The terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

- Determine the nature of the material to be pumped

Latest articles

-

The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

-

What are the materials used to construct the pump?

-

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

-

Aier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

-

I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

-

Slurry pump considerations

Links

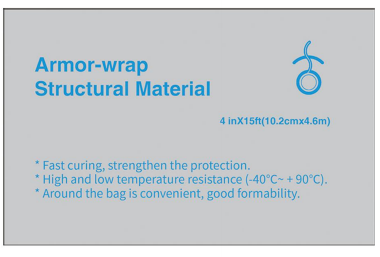

- One of the key advantages of butyl rubber tape is its excellent adhesion properties. When applied to a surface, the tape forms a strong bond that is resistant to water, oil, and chemicals. This makes it ideal for sealing leaks in pipes, roofs, windows, and other surfaces where a watertight seal is required.

- In addition to its versatility, self-amalgamating tape also boasts excellent weather resistance

- In addition to its strength and versatility, Flex Seal Black Tape also boasts excellent adhesion properties

Wait, it gets hotter.

- Renewable Energy In solar and wind power systems, the insulation of busbars is crucial for protecting the components from harsh environmental conditions, ensuring efficiency and reliability.

For example, PVC electrical tape can withstand temperatures up to 176 degrees Fahrenheit, while rubber electrical tape can handle temperatures up to 221 degrees Fahrenheit.

Control boxes mounted on floors are essentially large-scale boxes specialized for industrial use. They are installed on the floor due to their relatively heavier weight. The heavy weight means that their portability is reduced and it is impractical to mount them on walls.

How to Apply Butyl Rubber Sealant Tape

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.

flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.One of the most significant advantages of silicone insulation tape is its ability to withstand high temperatures. It can endure extreme heat up to 500°F (260°C) without losing its insulating properties. This thermal stability is crucial in environments where electrical components generate significant heat, ensuring that equipment operates safely and efficiently. In contrast to other insulating tapes, silicone tape maintains its integrity under thermal stress, making it a preferred choice among engineers and technicians.

2. Superior Adhesion Butyl rubber features high adhesive properties that allow it to bond effectively to various surfaces, including wood, metal, and plastic. This characteristic ensures a tight seal against drafts, moisture, and dust, enhancing the overall energy efficiency of your space.

These are typical control boxes designed to be installed on walls. This wall-mounted installation is preferred because it saves you space and makes it easier for you to access your box. Wall-mounted control boxes are commonly utilized in building systems, laboratories, and factory systems.

Advantages of Polyester:

Furthermore, self-bonding rubber tape is often used in hobbies and craft projects. Artists and DIY enthusiasts appreciate its flexibility and the variety of color options available, allowing them to create unique designs while enjoying the same reliability offered in more practical applications.

Another critical application of yellow electrical tape is for safety signaling. In environments where electrical work is ongoing, it is imperative to indicate areas that are off-limits or require caution. By wrapping yellow tape around specific zones or equipment, workers can alert others to potential hazards. This visual cue is crucial for minimizing accidents and injuries on the job site, which is a critical aspect of workplace safety protocols.

Another noteworthy feature is its resistance to extreme temperatures. Self-fusing rubber tape can typically withstand temperatures ranging from -20°C to 150°C (-4°F to 302°F), making it suitable for both high- and low-temperature environments. This attribute makes it especially useful in electrical applications, automotive repairs, and around the home, where temperature fluctuations are common.

self fusing rubber tape

Safety and compliance are non-negotiable when it comes to control boxes. Adherence to standards ensures your control box can reliably do its job while keeping users safe. Here are vital standards to keep in mind:

butyl rubber tape manufacturers. Their butyl rubber tape is known for its high strength and resistance to oil, fuel, and other harsh chemicals. It is commonly used for sealing body panels, windows, and other components on race cars.

fireproof tape for fireplace. Its flexible nature allows it to conform to various surfaces, and it remains effective over time without losing its heat-resistant properties. It's a cost-effective solution that can significantly enhance fireplace safety without compromising on aesthetics.

fireproof tape for fireplace. Its flexible nature allows it to conform to various surfaces, and it remains effective over time without losing its heat-resistant properties. It's a cost-effective solution that can significantly enhance fireplace safety without compromising on aesthetics.