high quality warman slurry pump drawings manufacturers

Latest articles

Slurry pump vs mud pump

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreWhat are the materials used to construct the pump?

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreFine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreDepending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreAnother important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreDetermine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreIn AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read More>Slurry Pump

high quality warman slurry pump drawings manufacturers...

high quality warman slurry pump drawings manufacturers 【high quality warman slurry pump drawings manufacturers】

Read More

Popular articles

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- Slurry pump vs mud pump

- If you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

- Dry Installation

Latest articles

-

If you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

-

- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

-

Step 1

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

Typical Applications of slurry pump

-

Conveying medium

Links

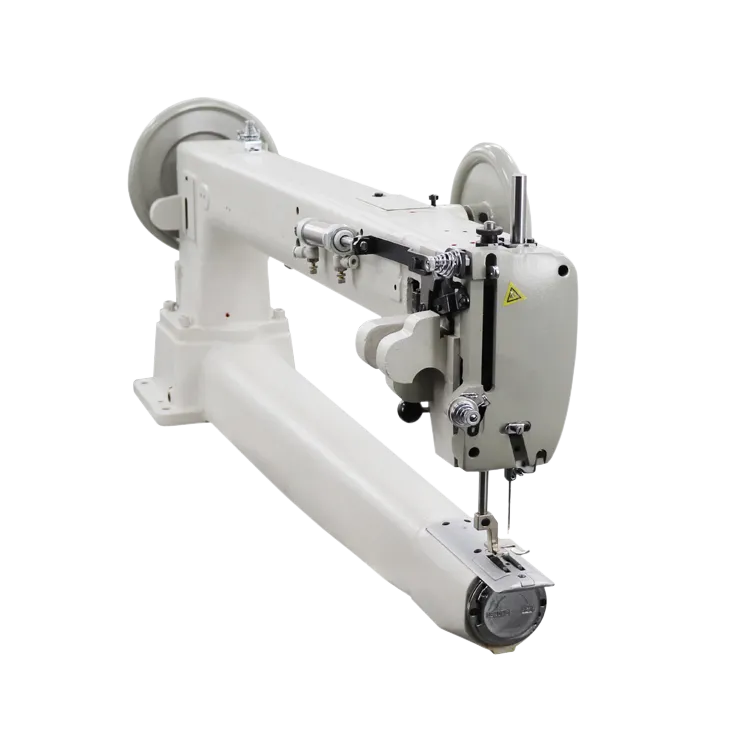

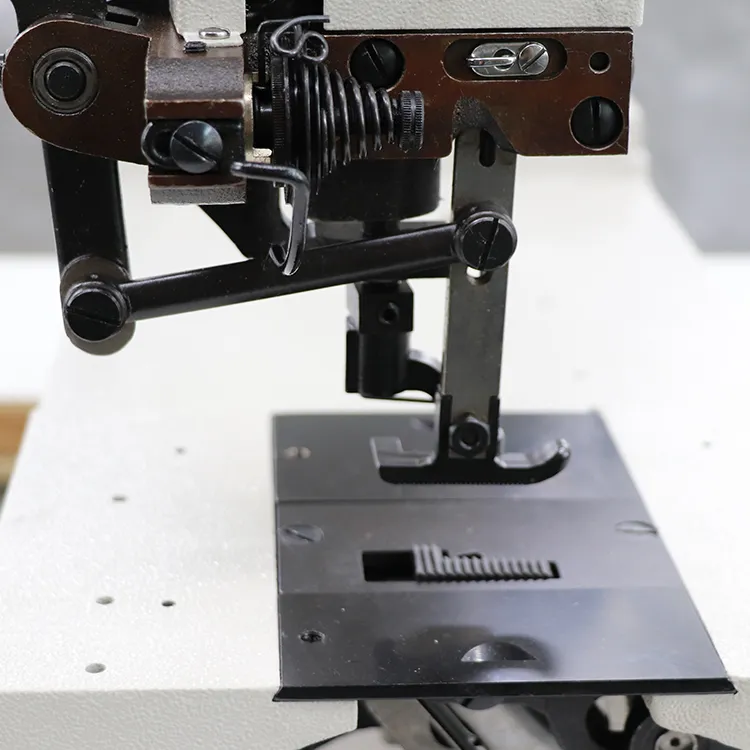

Modern industrial leather sewing machines are equipped with specialized features such as walking feet, which help move the thick material smoothly through the machine. They also typically possess a powerful motor capable of stitching through multiple layers of leather without skipping stitches. This evolution has made it possible for manufacturers to produce leather goods more efficiently while maintaining high standards of quality.

2. Durability and Reliability Gunny bags are inherently heavy-duty, and sewing machines designed for these materials ensure that the seams are robust enough to withstand wear and tear. This reliability minimizes the need for repairs and replacements, further enhancing operational efficiency.

In the agriculture sector, for example, the ability to quickly and effectively seal bags of grains or fertilizers is critical. It helps in preventing spoilage and pests while ensuring that the products remain intact until they reach the consumer.

The Best Sewing Machines for Upholstery A Comprehensive Guide

One of the key advantages of automatic quilting machines is their speed. These machines can quilt much faster than a person could ever stitch by hand, allowing for more quilts to be produced in a shorter amount of time. This is especially useful for businesses that need to mass-produce quilts or for individuals who want to quickly finish a project. By using an automatic quilting machine, the entire quilting process is streamlined and expedited.

Conclusion

3. Cutting Tools Sharp scissors or a rotary cutter will make cutting through heavy canvas cleaner and easier. A cutting mat can also protect your surfaces while allowing precise cuts.

Versatility in Sewing Projects

5. Clips and Adhesives Unlike fabric, pins are not very effective on leather. Instead, use clips designed for thicker materials or fabric glue to hold pieces together before sewing.

Known for its reliability, the Janome HD3000 is a favorite among seasoned sewists. This machine offers 18 built-in stitches, a one-step buttonhole, and a solid aluminum body that enhances its sturdiness. The HD3000 has a unique needle threading system, which simplifies the process, reducing frustration for beginners and experienced crafters alike. Additionally, its drop feed setting makes this machine suitable for free-motion sewing and quilting, expanding its versatility.

5. Extended Work Area With a larger workspace, heavy duty sewing machines allow for easier handling of bulkier projects, making them ideal for quilting enthusiasts or professionals working on larger items.

Price Ranges

3. Consistent Seam Allowances Maintaining a consistent seam allowance is crucial. A variation as small as 1/8 inch can lead to misalignment. Consider using a quarter-inch foot for accuracy, especially in piecing.

Conclusion

The Union Lockstitch Sewing Machine is often equipped with adjustable settings, allowing operators to modify stitch length and tension according to their specific needs

. This flexibility means that whether you’re sewing delicate garments or robust workwear, you can achieve the desired results with precision.Workwear Manufacturing: Workwear manufacturing makes clothes like construction vests, firefighter uniforms, chef aprons, and mechanic overalls for specific jobs or businesses. Because these clothes are made to last and keep you safe, they often use solid fabrics and materials.

When you sew, one of the things you need to consider is balance. If you want a heavy machine that sits as solid on the sturdy sewing table, consider choosing a sewing machine. With a heavy machine, be assured you will feel the metal gliding along with every stitch.

When you sew, one of the things you need to consider is balance. If you want a heavy machine that sits as solid on the sturdy sewing table, consider choosing a sewing machine. With a heavy machine, be assured you will feel the metal gliding along with every stitch.

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects