sludge drainage pump

Latest articles

Dredge Pump Features

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read MoreThe concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read MoreIn this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read More- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read MoreThe selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read MoreTypes of damage to slurry pumps

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read MoreSlurry Pump

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read MoreThe FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read More- Keeping clean catch basins clean from solids

sludge drainage pump...

sludge drainage pump 【sludge drainage pump】

Read More

Popular articles

- A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

- To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- Light-duty Slurry Pump

- Because of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

Latest articles

-

Dredge Pump Features

-

There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

-

For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

-

Slurry Pump

-

Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

Links

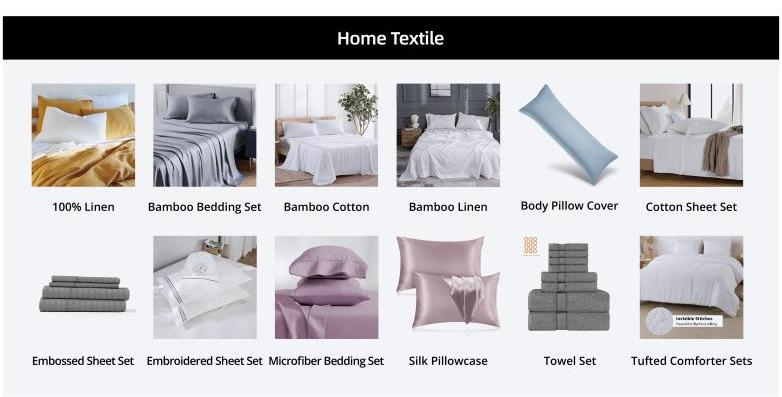

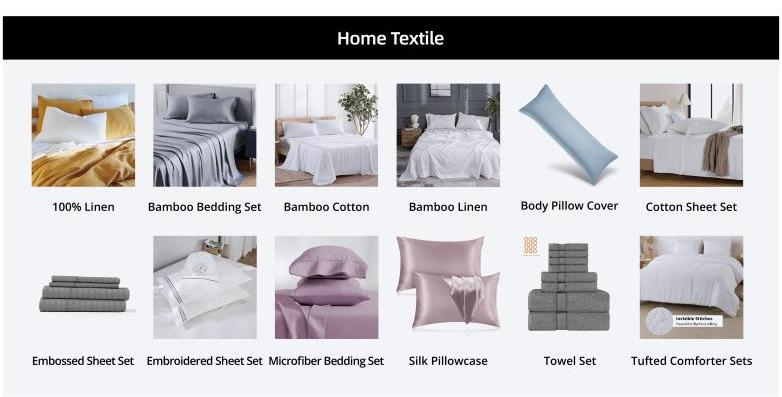

- In conclusion, high-quality satin sheets elevate the bedtime experience, blending style with comfort. They are not only a treat for the senses but also provide practical advantages for skin and hair health. Whether you're seeking a touch of indulgence or a practical upgrade to your sleep routine, investing in these sheets is a decision you won't regret. After all, quality sleep is the foundation of a healthy lifestyle, and there's no better way to ensure it than with the soft, smooth embrace of high-quality satin sheets.

- * Tumble dry the insert on low heat until it is completely dry. Avoid overdrying, as this can damage the feathers and reduce their insulating properties.

Cleaning and Caring for Linen Sheets

BTW, if you want to check out White Goose Down Pillows and Duvets, you can visit our collections page.

However, the process ofturning bamboo into viscose fabricrequires the use of acidic or toxic chemicals, as well as using large amounts of water, dyes, and finishing chemicals. This is important to note because this processing does have a negative environmental impact, even though there are many positives to bamboo as a sustainable material.

Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests

Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests wholesale hotel linens.

wholesale hotel linens.The best quality duvet covers are frequently made from advanced fabrics such as poly-fiber, which is composed of extremely fine, synthetic fibers and often used to produce high-tech exercise clothing. Because of the short strands, this material is excellent for night sweats because it allows moisture to escape rather than be absorbed by the body. The poly-fiber that is used in duvet covers is often brushed to give it a softer texture. Home City Inc.’s duvet covers have been finished with a brushed finish, which results in an ultra-soft 1500 threads per square inch. They are also more robust and stain and fade resistant than cotton, making them an excellent choice for daily use. Furthermore, because they are made of inorganic materials, duvet covers are hypoallergenic and can help to reduce the frequency of allergy attacks.

PERCALE SHEETS Percale sheets are made from tightly woven cotton, polyester, or silk. These sheets vary from traditional sheets because of its “percale” style of weave. They also tend to be very durable, and leave a luxurious feel on the skin.

luxury hotel linens. This means that guests can enjoy the luxurious feel of the linens throughout their stay, without any worry of wear or tear.

It’s also important to consider the quality of the microfiber sheet. Choose a set made from high-quality microfiber as this will ensure the sheets are soft, smooth, and less prone to sweating. Additionally, washing your Microfiber sheets with mild detergent and avoiding fabric softeners can help maintain their moisture-wicking properties.

Black Bed Sheets

Silk sheets are known for their luxurious feel and smooth texture. Silk sheets are naturally hypoallergenic and can help regulate body temperature, making them a great choice for those with sensitive skin or allergies. When choosing silk sheets, look for ones with a higher millimeter weight, which indicates the quality and durability of the silk. Mummy weights of 19 or higher are considered ideal for silk sheets.

Duvet covers also serve to protect your duvet from rips, stains, and ordinary wear and tear, as previously mentioned. While you will still need to wash your duvet, it will be needed far less frequently due to the cover.

Egyptian Cotton

However, excessive thread counts mean little if the fibers used are of low quality. Extra long staple cotton for beddings is best to maintain the durability of cotton fabrics. This ensures cotton bed sheets will not fray, wrinkle or pill easily after a few tumbles in the wash.