china mini slurry pump supplier

Latest articles

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read More3. Both pumps and motors are designed separately.

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MoreDredge Pump

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MorePumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MoreTwo types of slurry are found in these industries.

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MoreSlurry Pump VS Mud Pump

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MoreSlurry Pump Speed

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

china mini slurry pump supplier...

china mini slurry pump supplier 【china mini slurry pump supplier】

Read More

Popular articles

- The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

- What is a dredging pump?

- Sump drainage or washdown

- The selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

- - Pumping the final product in a process

- Horizontal pumps are the most commonly used type of slurry pump and therefore have the advantage of being easy to install or maintain, a wide range of flow parameters to choose from and a wide range of design materials to choose from. One of the advantages of vertical pumps, however, is the relatively small amount of floor space required for installation.

Latest articles

-

>Slurry Pump

-

Selecting a dredge pump

-

As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

-

To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

-

The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

-

Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

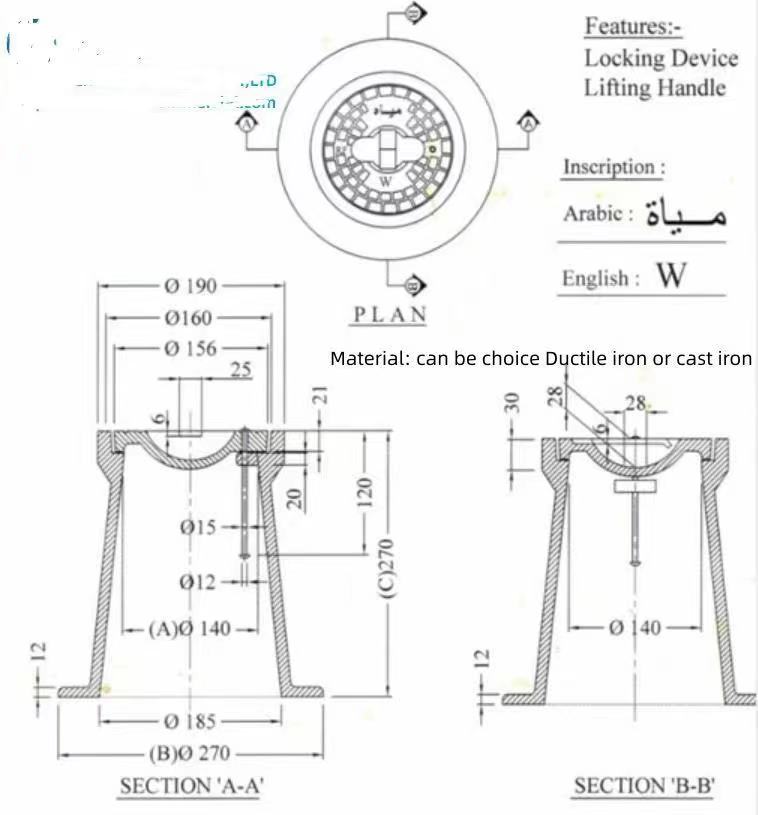

Links

Safety is another paramount concern for manhole cover companies. A poorly fitted or damaged cover can pose serious risks to pedestrians and vehicles. Companies invest in rigorous testing standards and quality assurances to ensure their products meet safety regulations. Furthermore, features such as anti-slip surfaces and reflective markings are being integrated into designs to enhance visibility and safety, especially in poorly lit areas.